Wearing influencing factor tester of yarn in porcelain eye position

A technology of influencing factors and testers, applied in the direction of testing wear resistance, using repetitive force/pulse force to test the strength of materials, instruments, etc., to achieve the effect of convenient operation and high test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

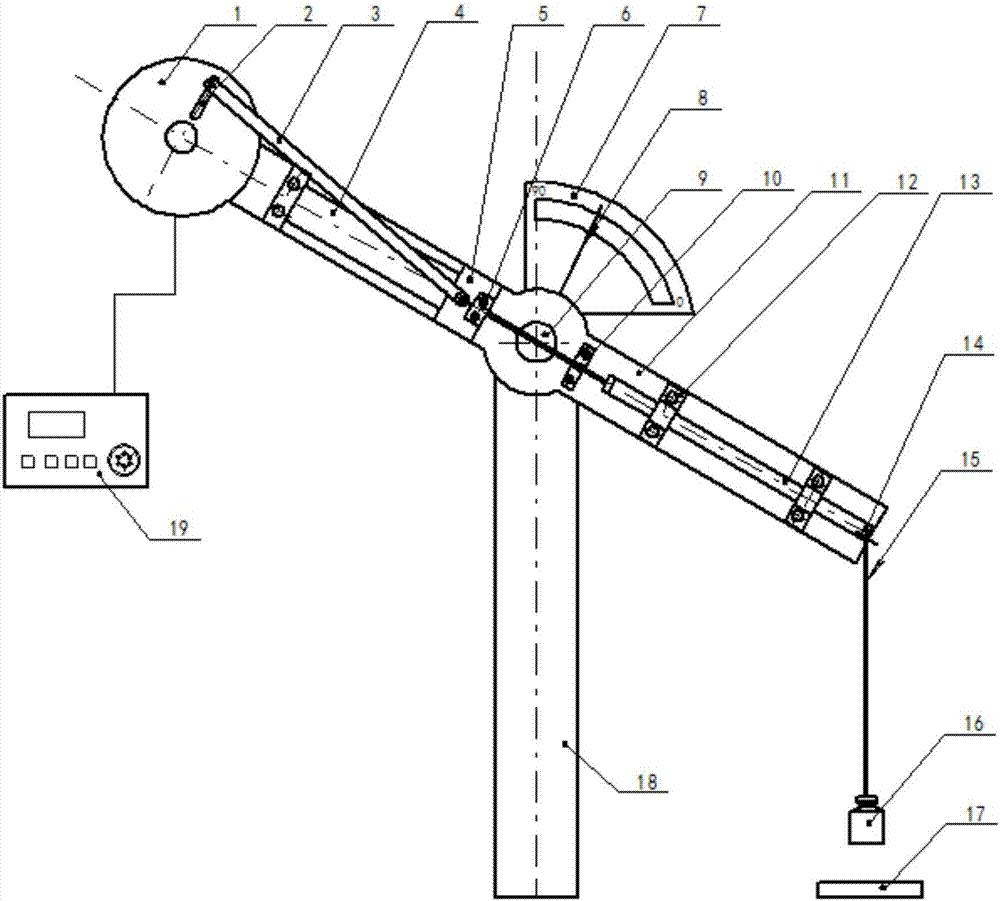

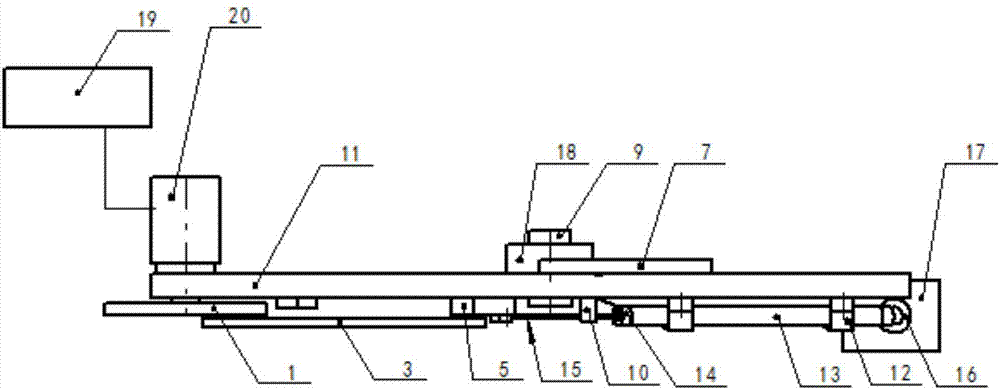

Method used

Image

Examples

Embodiment 1

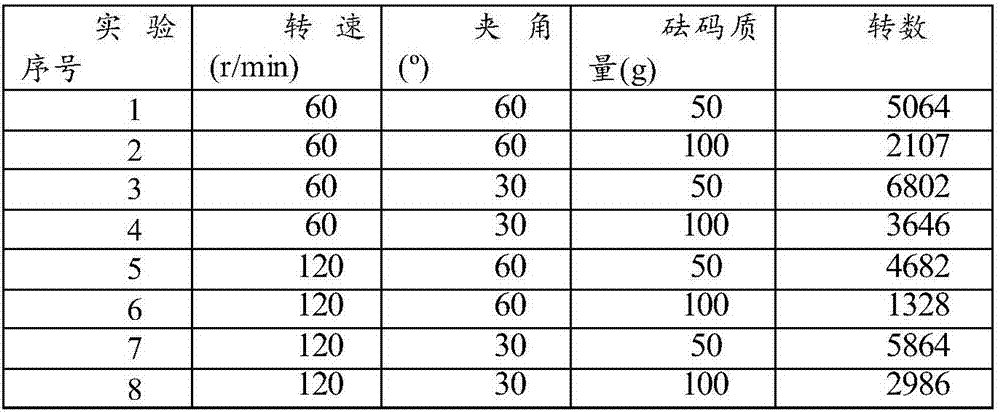

[0031] Embodiment 1: The yarn is fixed on the tester, and by changing the motor speed, the angle between the axis of the hollow tube and the yarn to be tested, and the weight of the weight, the number of revolutions of the motor when the yarn is broken under different conditions is recorded.

[0032] Step 1: Fix one end of the 3K carbon fiber multifilament to the upper end of the slider, pass through the hollow tube and connect with the weight. The aperture of the porcelain eye is 5mm, the yarn friction length is 5cm, and the material is ceramic.

[0033] Step 2: Adjust the speed controller, the angle pointer and the weight of the weight. When the carbon fiber fracture occurs at the friction position with the porcelain eye, it is recorded as a valid sample, and record the number of revolutions on the display of the number of revolutions at this time. See Table 1.

[0034] Table 1 Friction performance test of 3K carbon fiber multifilament ceramic eye

[0035]

Embodiment 2

[0036] Embodiment 2: The yarn is fixed on the tester, the revolution control button is set, and the yarn wear resistance test is carried out by changing the motor speed, the angle between the hollow tube axis and the yarn to be tested, and the weight of the weight. After the yarn is rubbed, the yarn strength test is carried out, and the strength damage rate of the yarn is calculated.

[0037] Step 1: Fix one end of the 3K carbon fiber multifilament to the upper end of the slider, pass through the hollow tube and connect with the weight. The aperture of the porcelain eye is 5mm, the yarn friction length is 5cm, and the material is ceramic.

[0038] Step 2: Adjust the speed controller, angle pointer and weight weight, set the number of rotation control button to 100 rpm, and perform a strength test on the original carbon fiber multifilament and the sample after friction. The breaking strength of the original carbon fiber multifilament is 171N. The original carbon fiber multifil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com