Comprehensive high-performance bearing grinding burn inspection and judgment method

A grinding burn and determination method technology, applied in the direction of material magnetic variable, etc., can solve the problem of low detection rate of bearing raceway grinding burn, achieve production quality and use reliability guarantee, improve detection rate, and promote production The effect of technical ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

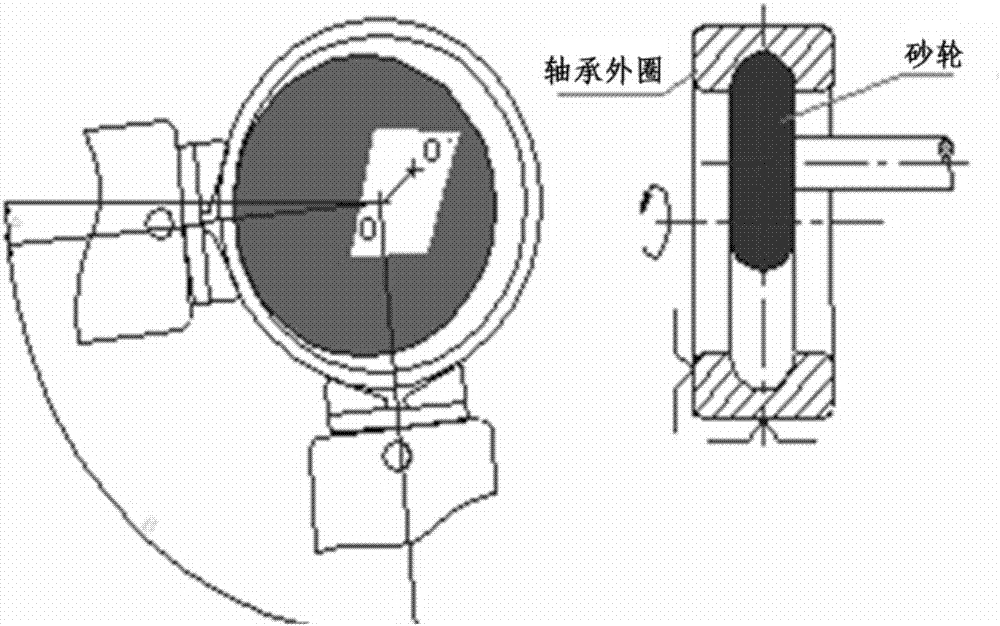

[0015] Specific implementation mode one: combine figure 1 To illustrate this embodiment, a high-performance bearing grinding burn comprehensive inspection and determination method described in this embodiment is realized through the following steps:

[0016] Step 1. In the production process, use single acid instead of mixed acid to inspect the outer ring of the bearing;

[0017] Step 2. Develop burn atlas;

[0018] Step 3: Carry out grinding burn inspection on the finished parts through the magnetoelastic instrument;

[0019] Step four, physical and chemical analysis and judgment.

[0020] In step 4, when both the pickling inspection and the magnetoelasticity test are judged to be abnormal, and further understanding of the degree of burn is required, the sample can also be cut and observed through a metallographic microscope. There are obvious differences, the bright white color is the quenching burn, and the black is the tempering burn. Usually the burn layer has a certai...

specific Embodiment approach 2

[0021] Specific implementation mode two: combination figure 1 To illustrate this embodiment, in step 1 of the method for comprehensive inspection and determination of high-performance bearing grinding burns described in this embodiment, the steps of using single acid instead of mixed acid in the production process to inspect the bearing steel ring are as follows:

[0022] Step 1 (1), degreasing: use a mixed solution with anhydrous carbonic acid content of 2.5-3.5%, trisodium phosphate content of 2.5-3.5%, sodium hydroxide content of 1-2%, and water glass content of 0.2-0.3% Clean the parts, the cleaning temperature is 75 ℃ ~ 85 ℃, and the cleaning time is 3 minutes;

[0023] Step 1 (2), continuous water film inspection: make the surface of the part completely wet, and within 30 seconds of visual observation, it is qualified if there is no water film on the surface of the part;

[0024] Step 1 (3), hydrochloric acid impregnation: impregnate the parts with a hydrochloric acid s...

specific Embodiment approach 3

[0030] Specific implementation method three: the burn atlas is formulated in step 2 to facilitate comparison and identification during the inspection process, sort out and classify the appearance, degree, and distribution position of the ground burnt parts, and formulate the atlas of pickled burnt parts, and take parts after pickling Compare with the map topography to ensure that the burned parts are effectively identified and avoid misjudgments and missed judgments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com