Overspeed electronic load system

An electronic load and control system technology, applied in the direction of power supply testing, measurement of electrical variables, improvement of basic electrical components, etc., can solve the problem that resistance boxes and electronic loads cannot meet requirements, cannot meet load switching speed requirements, and mechanical switch switching speed is slow. and other problems, to achieve the effect of fast switching speed, fast speed, and fast current response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and examples, so as to fully understand and implement the process of how to apply technical means to solve technical problems and achieve technical effects in the present invention. It should be noted that, as long as there is no conflict, each embodiment and each feature in each embodiment of the present invention can be combined with each other, and the formed technical solutions are all within the protection scope of the present invention.

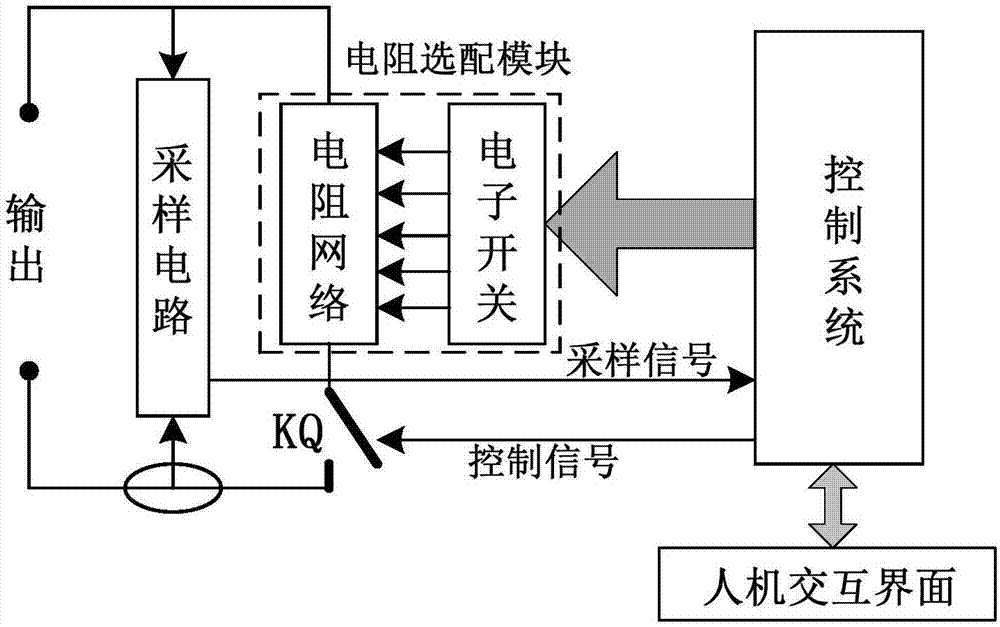

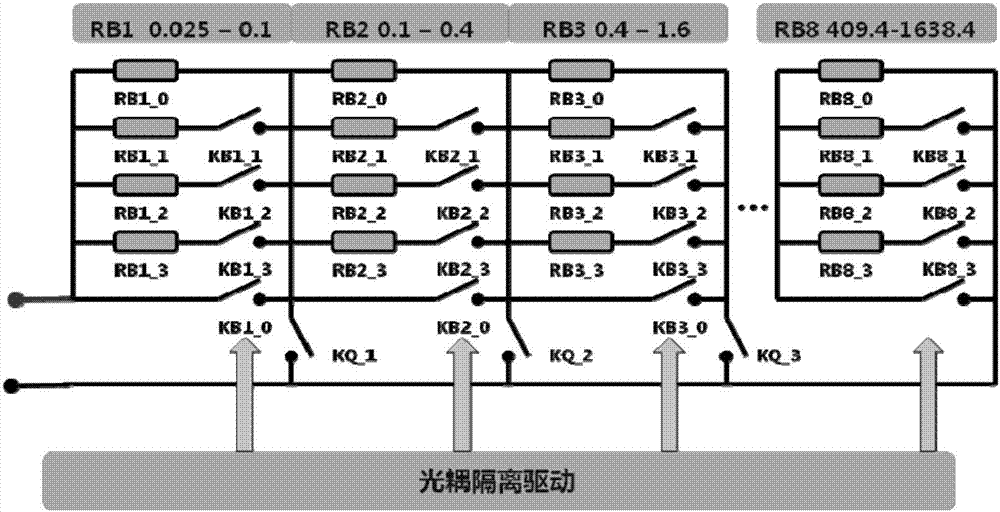

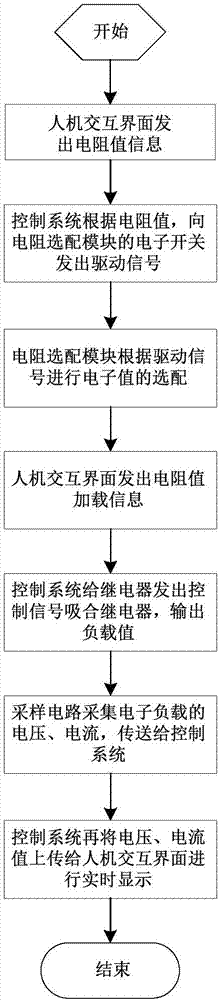

[0022] figure 1 It is a block diagram of the patented electronic load system of the present invention. As shown in the figure, an ultra-fast electronic load system mainly includes a human-computer interaction interface, a control system, a resistance matching module, a sampling circuit, and an output port. The human-computer interaction interface is connected with the control system, and transmits data betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com