Pixel structure and liquid crystal display panel

A technology of pixel structure and substrate substrate, applied in nonlinear optics, instruments, optics, etc., can solve the problems of light leakage of the gate line of the curved liquid crystal display, affecting the pixel charging rate, etc., to improve display performance, voltage stability, The effect of increasing the aperture ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In order to solve the above-mentioned technical problems existing in the prior art, an embodiment of the present invention provides a pixel structure.

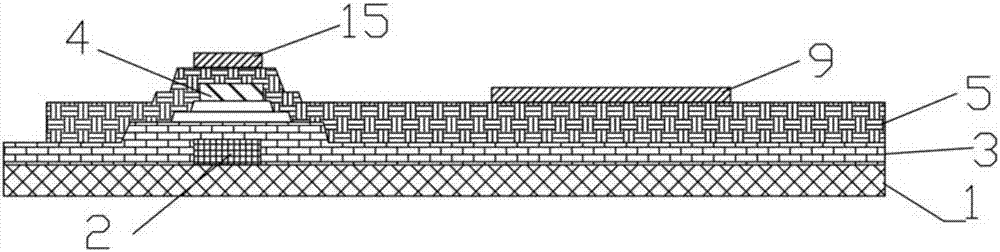

[0038] figure 1 A schematic cross-sectional structure diagram of a pixel structure according to Embodiment 1 of the present invention is shown. figure 2 show figure 1 A top view of the pixel structure shown in .

[0039] refer to figure 1 and figure 2 The pixel structure of this embodiment includes a base substrate 1 , a first metal layer 2 , a first insulating layer 3 , a transparent electrode layer, a second metal layer 4 and a second insulating layer 5 .

[0040] Specifically, the first metal layer 2 is formed on the base substrate 1 , and the first metal layer 2 includes a pattern of gate lines 13 . The first insulating layer 3 is formed on the first metal layer 2 . The second metal layer 4 is formed on the first insulating layer 3 . The second metal layer 4 includes a pattern of data lines 14 . The second...

Embodiment 2

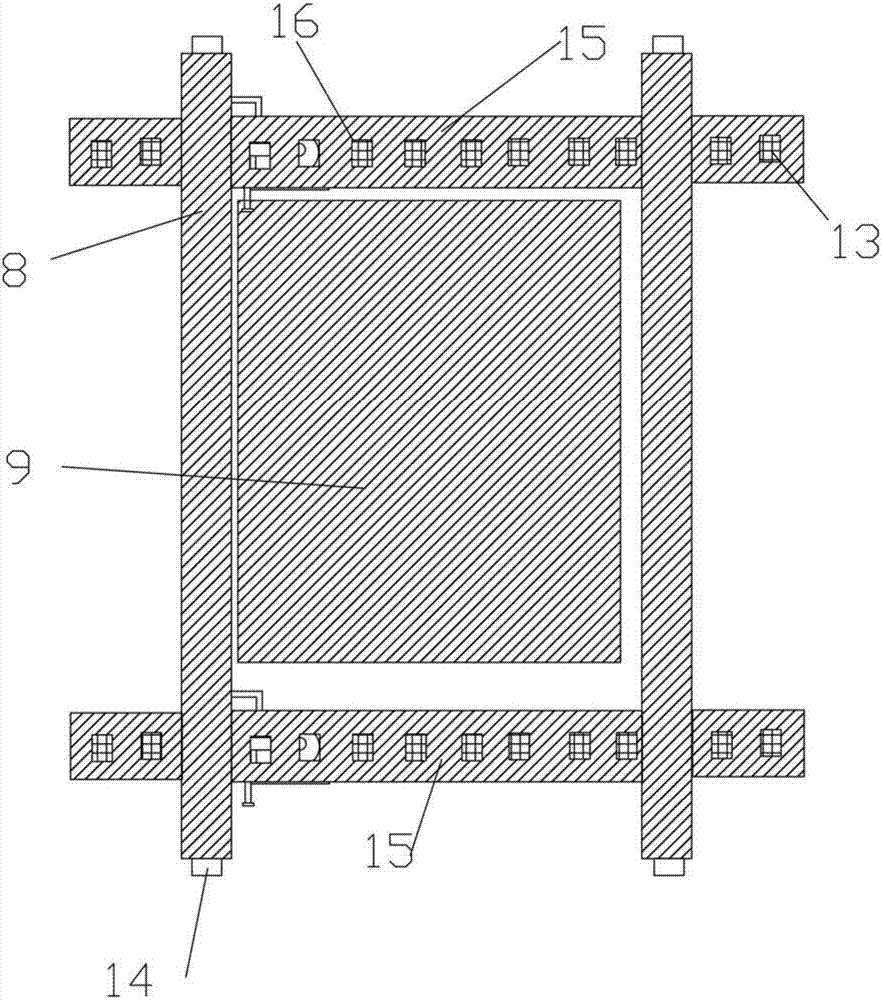

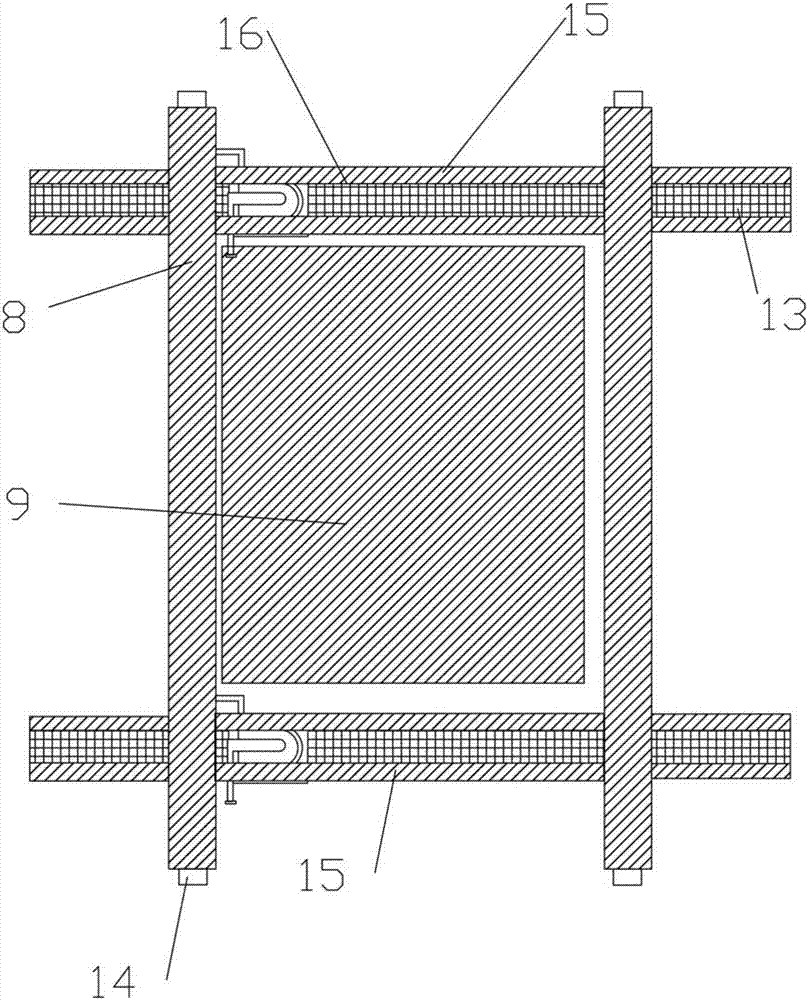

[0046] Correspondingly, image 3 A top view of a pixel structure according to a second embodiment of the present invention is shown. refer to image 3 In this embodiment, on the basis of the first embodiment, the structures of the color-resist layer 6 , the third insulating layer 7 and the transparent electrode layer of the pixel structure are limited.

[0047] Specifically, the color resist layer 6 is formed on the second insulating layer 5 to function as a light filter. The third insulating layer 7 is formed between the color resist layer 6 and the transparent electrode layer, and is used to insulate the color resist layer 6 from the transparent electrode layer. Meanwhile, the transparent electrode layer also includes the pattern of the second transparent electrode 8 , the projection of the second transparent electrode 8 on the second metal layer 4 covers the data line 14 , and the pixel electrode 9 is insulated from the second transparent electrode 8 .

[0048] Therefore...

Embodiment 3

[0055] Correspondingly, Figure 4 A schematic structural diagram of a liquid crystal display screen having the pixel structure of the first embodiment is shown.

[0056] refer to Figure 4 , the liquid crystal display in this embodiment is a liquid crystal display in PSVA mode, and the liquid crystal display is a curved liquid crystal display. The liquid crystal display screen includes a plurality of pixel structures in the first embodiment above.

[0057] The pixel structure of the liquid crystal display of the present invention further includes a liquid crystal layer 10 , a common electrode layer 11 , a color resist layer 6 and an upper glass substrate 12 .

[0058] An upper glass substrate 12 is formed above the transparent electrode layer, the color resist layer 6 is formed on the lower side of the upper glass substrate 12, a common electrode layer 11 is formed on the lower side of the color resist layer 6, and the liquid crystal layer 10 is arranged between the transpar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com