Wet type dust collection device for wood dust

A wet dust removal and dust technology, applied in the combined device, the use of liquid separation agent, the separation of dispersed particles, etc., can solve the problems of increasing equipment control ability, and achieve the effect of improving efficiency, simple structure and easy manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

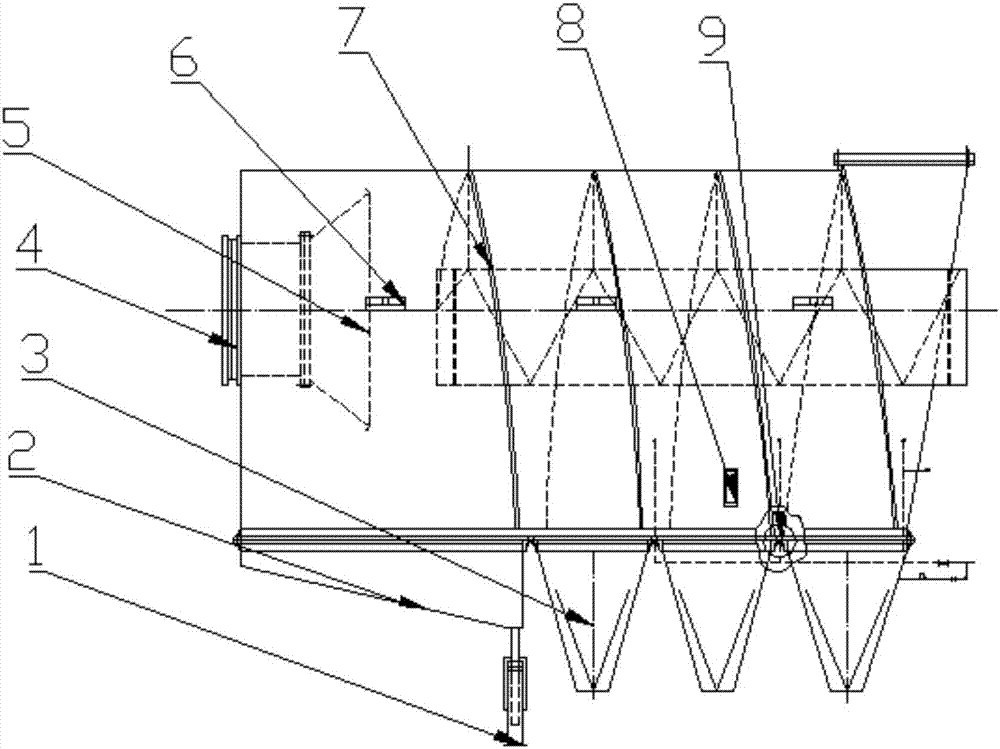

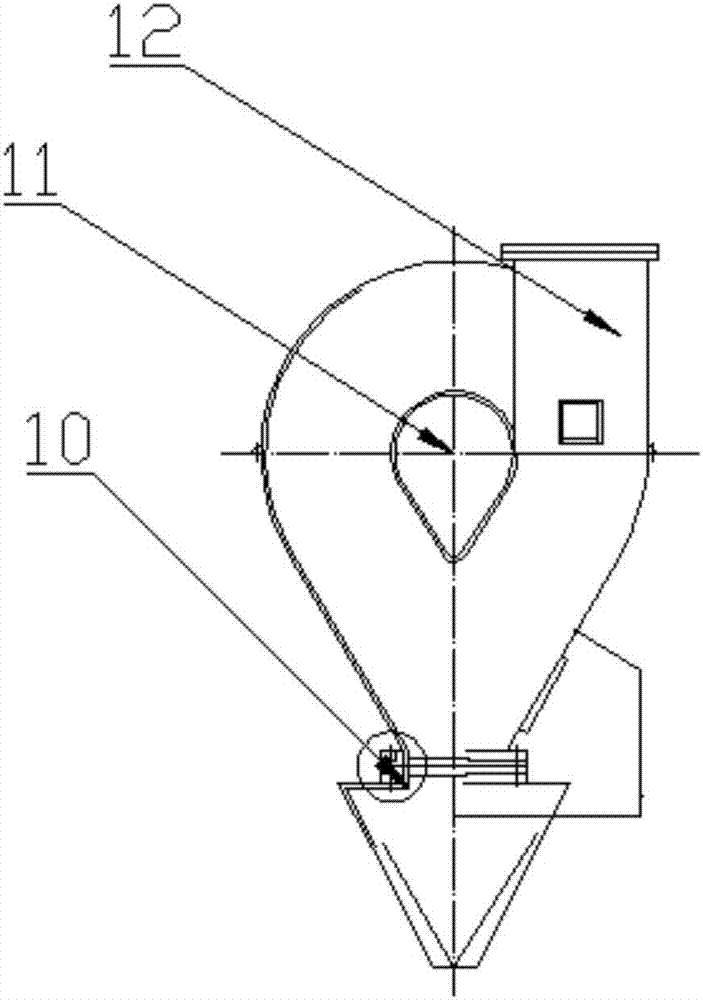

[0015] The present invention will be further described below in conjunction with accompanying drawing:

[0016] Such as Figure 1-Figure 2 As shown, a wet dust removal device for wood dust includes ash discharger 1, exhaust fan 5, spiral deflector 7 and water adder 10, and a mortar bucket 2 is communicated with the top of the ash discharger 1, which can collect and Dust is regularly discharged. The mortar hopper 2 is equipped with a plurality of air outlets 3 inside, which can extract dust. An agitator 4 is installed on the outer side of the upper end of the air outlet 3, which can carry out agitation, transportation and diversion of dust. The inside of the agitator 4 is connected There is the exhaust fan 5, which can play the role of drafting. The inside of the exhaust fan 5 is equipped with a water film 6, which can further filter dust. For diversion, a water gauge 8 is installed at the lower end of the spiral deflector 7, which can detect the amount of internal water. A sp...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap