Comprehensive treatment device of cement rotary kiln flue gas

A cement rotary kiln and comprehensive treatment technology, which is applied in combined devices, waste heat treatment, dispersed particle filtration, etc., to achieve high denitrification efficiency, ingenious structure, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

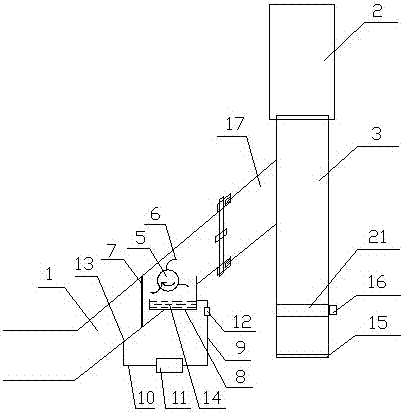

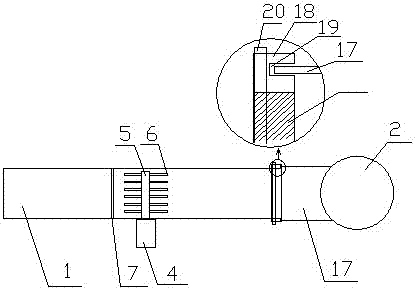

[0022] As shown in the figure, a cement rotary kiln flue gas comprehensive treatment device according to the present invention includes a waste gas inlet pipe 1, a denitrification device, a dust removal device, a waste gas outlet pipe 2, and a dust removal bag 3. The waste gas inlet pipe 1 is inclined. Set upwards, the denitration device includes a motor 4, a rotating shaft 5, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap