Filter frame used for conventional chip cleaner

A chip conveyor, conventional technology, applied in the direction of metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., to achieve excellent filtering effect, high filtering precision, and solve the effect of low filtering precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

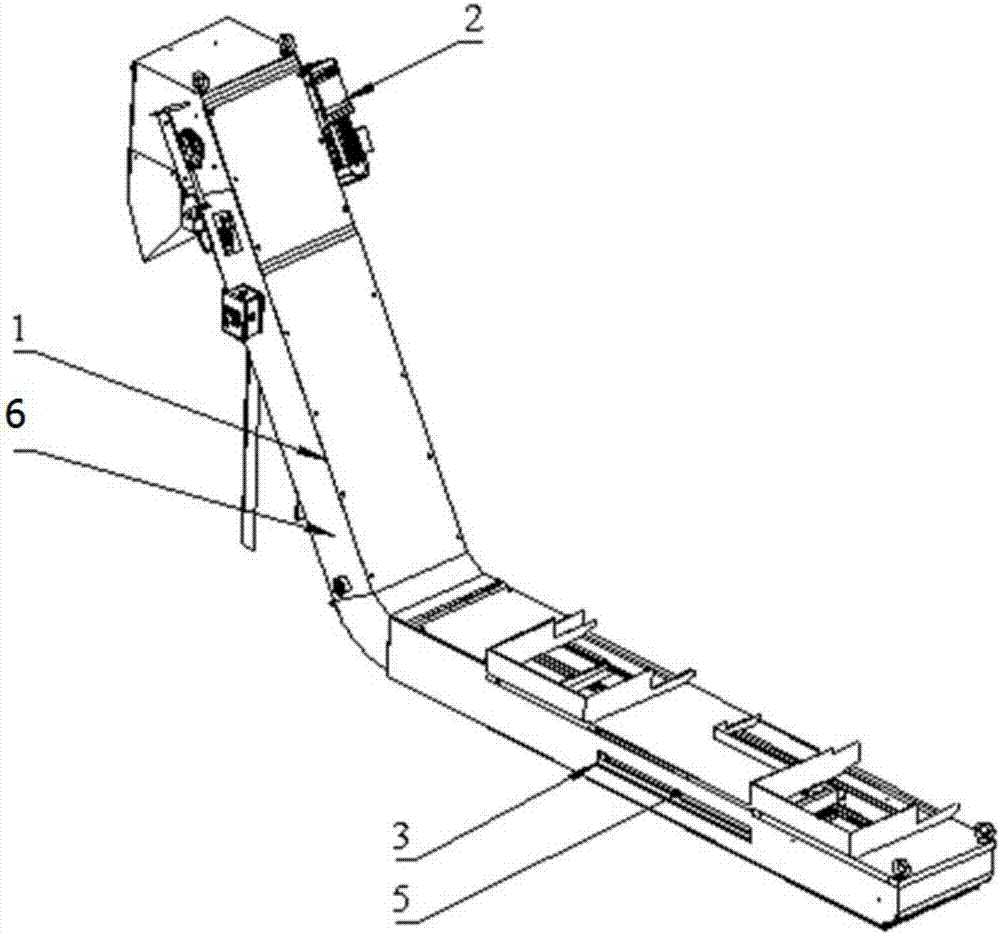

[0029] Example 1, such as Figure 1-6 Shown:

[0030] A filter frame for a conventional chip conveyor, comprising at least one filter frame 3 and at least one filter screen plate 8 with a thickness of 0.5mm-0.6mm; the filter screen plate 8 is matched and installed in the filter frame 3, and the filter screen A number of filter holes are arranged on the plate 8, and the filter holes are formed by array etching by photolithography or chemical milling, and the filter screen plate 8 includes an opening upper part 9 and an opening lower part 10; the structure of the filter holes includes a single cone structure, Straight pore structure and double-cone pore structure, wherein the double-cone pore structure includes an upper filter hole and a lower filter hole, the upper filter hole is located at the upper part 9 of the opening, the lower filter hole is located at the lower part 10 of the opening, and the upper filter hole and the lower filter hole The large ends of the tapered hole...

Embodiment 2

[0043] Example 2, such as Figure 1-6 Shown:

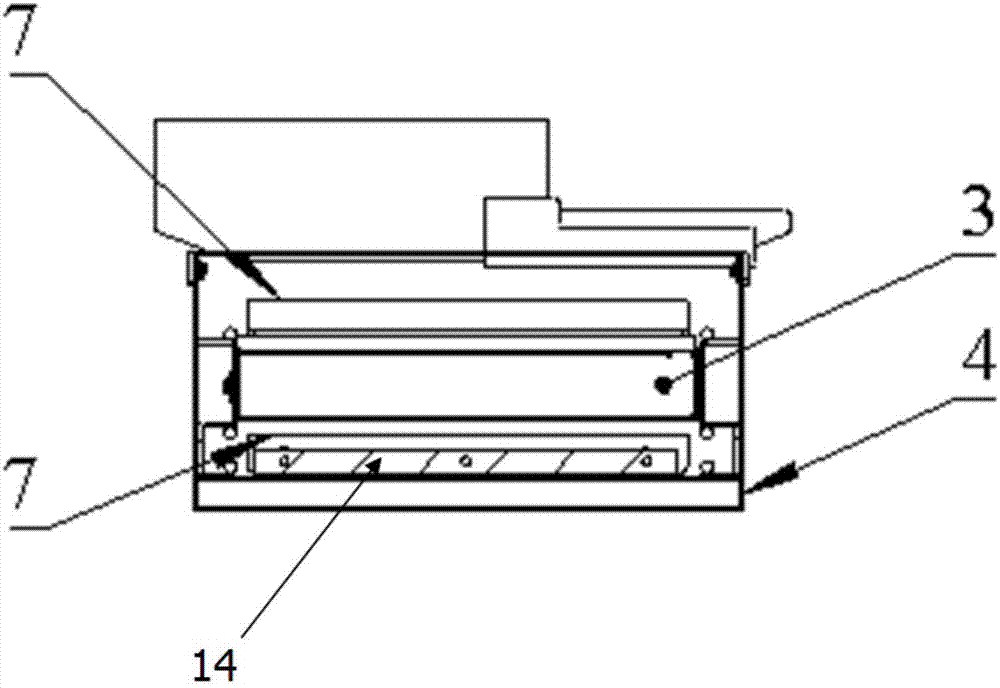

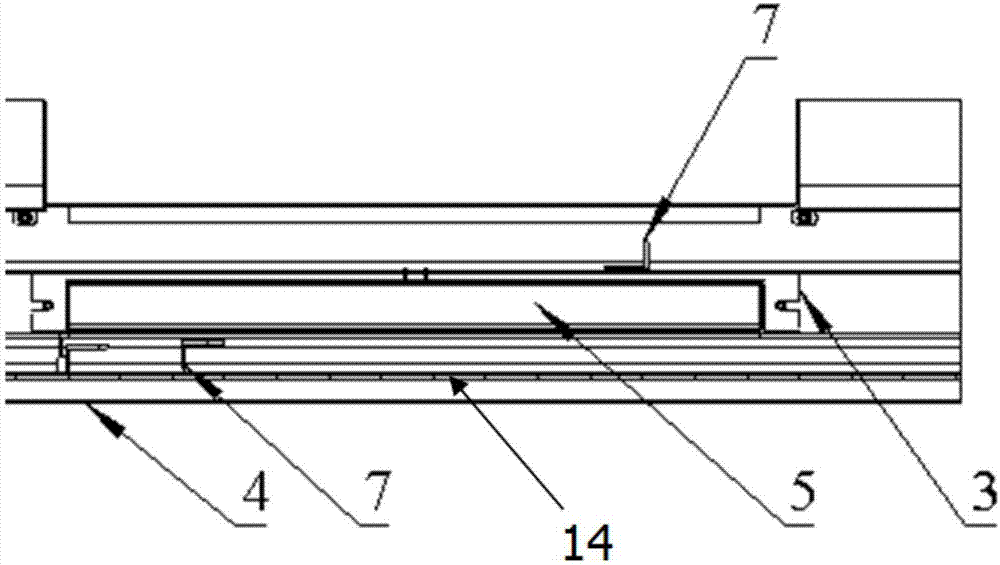

[0044] figure 1 It is an axonometric view of the chip conveyor body 1 of the present invention. In the figure, 3 is a filter frame. The chip conveyor body 1 also includes a liquid outlet 5, and the liquid outlet 5 conveys the cutting fluid filtered by the filter frame 3. exist figure 2 In , it is shown that a filter frame 3 is arranged inside the chain 14, that is, between the upper part and the lower part of the chain 14, for filtering cutting fluid. By placing the filter frame 3 inside the chain 14, the filter frame 3 is protected from large chips. There can be one or more filter frames 3 connected to the same chip conveyor inside the chip conveyor body 1, and the number of filter frames is determined according to the required flow rate, the amount of cutting fluid used and the frequency of cleaning. For example, if a large amount of cutting fluid is required, the number and size of filter frames 3 should be increased. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com