Blade preparation method and blade

A technology for blades and installation parts, which is applied to earth movers/shovels, construction, etc. It can solve problems such as difficulty, large investment in mass production, and irreversibility, and achieve stable mechanical properties, excellent comprehensive performance, and reduced installation costs. effect of number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

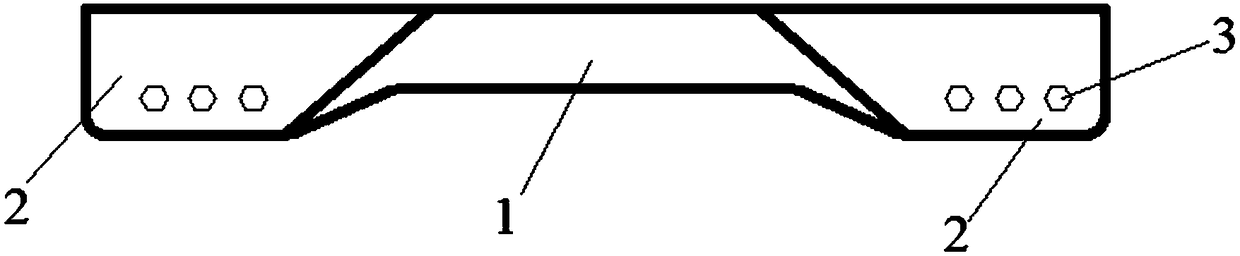

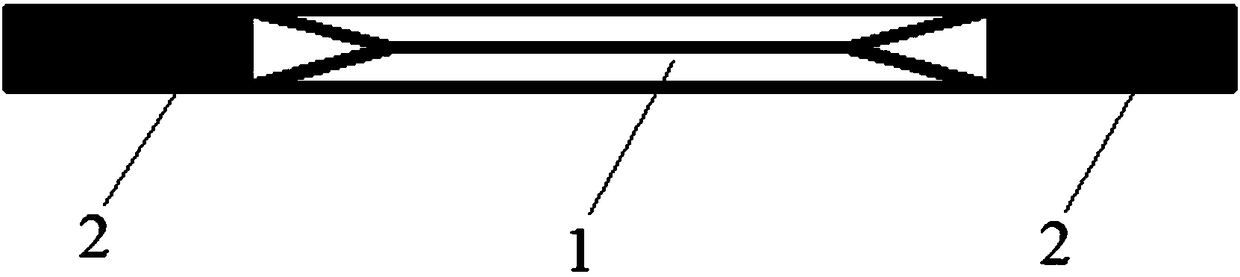

[0025] According to an aspect of the present invention, there is provided a method for preparing a blade, including:

[0026] Smelting high-purity alloys as raw materials, and processing the raw materials into blade blanks;

[0027] Pre-open mounting holes for the blade blanks to obtain semi-finished blades;

[0028] Forging and rolling of semi-finished blades to obtain finished blades;

[0029] Finish machining the mounting holes on the finished blade to obtain the blade;

[0030] Among them, the high-purity alloy contains: vanadium, chromium, boron, carbon, nickel, manganese, titanium, boron, and iron. The composition design used in the high-purity alloy is (wt%): vanadium: 0.016-0.019, chromium: 0.014- 0.017, boron: 0.001-0.002, carbon: 0.22-0.25, nickel: 0.0017-0.0019, manganese: 1.11, titanium: 0.0013-0.0021, cobalt: 0, molybdenum: 0, the balance is iron and unavoidable impurities.

[0031] Specifically, the purity of the blade blank is ensured by smelting alloy in a certain propor...

Embodiment 1

[0035] High-purity alloys are smelted through a vacuum furnace. Among them, the high-purity alloys contain: vanadium, chromium, boron, carbon, nickel, manganese, titanium, boron, and iron. The composition of the high-purity alloy is designed as (wt%): Vanadium: 0.016, chromium: 0.017, boron: 0.002, carbon: 0.22, nickel: 0.0017, manganese: 1.12, titanium: 0.0021, cobalt: 0, molybdenum: 0, the balance is iron and inevitable impurities.

[0036] Smelting high-purity alloys as raw materials, and processing the raw materials into blade blanks;

[0037] Pre-open mounting holes for the blade blanks to obtain semi-finished blades;

[0038] Forging and rolling of semi-finished blades to obtain finished blades;

[0039] Finish machining the mounting holes on the finished blade to obtain the blade.

Embodiment 2

[0041] High-purity alloys are smelted through a vacuum consumable furnace. Among them, the high-purity alloys contain vanadium, chromium, boron, carbon, nickel, manganese, titanium, boron, and iron. The high-purity alloys are designed with the following composition (wt%): Vanadium: 0.019, Chromium: 0.014, Boron: 0.001, Carbon: 0.25, Nickel: 0.0019, Manganese: 1.13, Titanium: 0.0013, Cobalt: 0, Molybdenum: 0, the balance is iron and inevitable impurities.

[0042] Smelting high-purity alloys as raw materials, and processing the raw materials into blade blanks;

[0043] Pre-open mounting holes for the blade blanks to obtain semi-finished blades;

[0044] Forging and rolling of semi-finished blades to obtain finished blades;

[0045] Finish machining the mounting holes on the finished blade to obtain the blade.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com