Pressure-relieving type hydraulic cutter capable of completing multi-layer cutting at a time

A multi-layer cutting and pressure relief technology, applied in the direction of wellbore/well components, earthwork drilling and production, etc., can solve the problem that mechanical cutting technology cannot meet the complex underwater conditions in deep sea, low cutting efficiency, lack of cutting completion and accurate judgment of cutting accidents and other problems, to achieve the effect of large opening angle of the blade, simple structure of the cutter, and less wearing parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

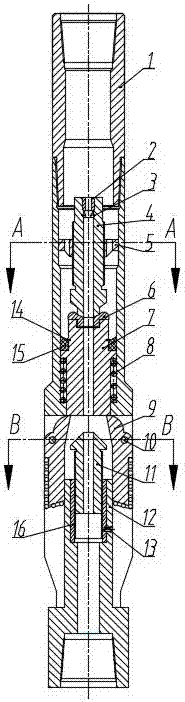

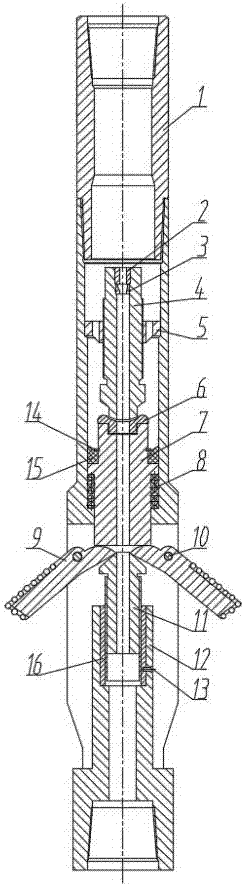

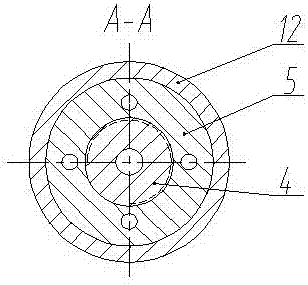

[0014] According to the drawings, the pressure-relieving hydraulic cutter that completes multi-layer cutting at one time is mainly composed of an upper joint, a nozzle, an O-ring, an upper center body, a limit block, a contact head, a piston, a spring, a sealing colloid, Retaining ring, blade, pin shaft, lower center body, threaded sleeve, limit screw, cutter body, is characterized in that the tool as a whole is composed of upper joint 1 and cutter body 12 through threaded connection, and the interior is composed of upper center body 4, limit block 5, piston 7, blade 9, and lower center body 11; Placed in the cutter body 12 through clearance fit; the piston 7 is cross-shaped, the upper end of the piston 7 is in contact with the upper center body 4 through a special contact head 6, the lower end of the piston 7 is always in contact with the blade 9, and the spring 8 is placed on the piston 7 In the cavity between the cutter body 12, the piston 7 is placed in the cutter body 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com