Maritime self-propelled wellhead installing operation device

A self-propelled and operational technology, applied in isolation devices, boreholes/well components, fire prevention equipment, etc., can solve problems such as fierce fire, strong heat radiation, and damage to wellhead control devices, so as to ensure equipment operation safety and improve mechanization degree, the effect of reducing the surface temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

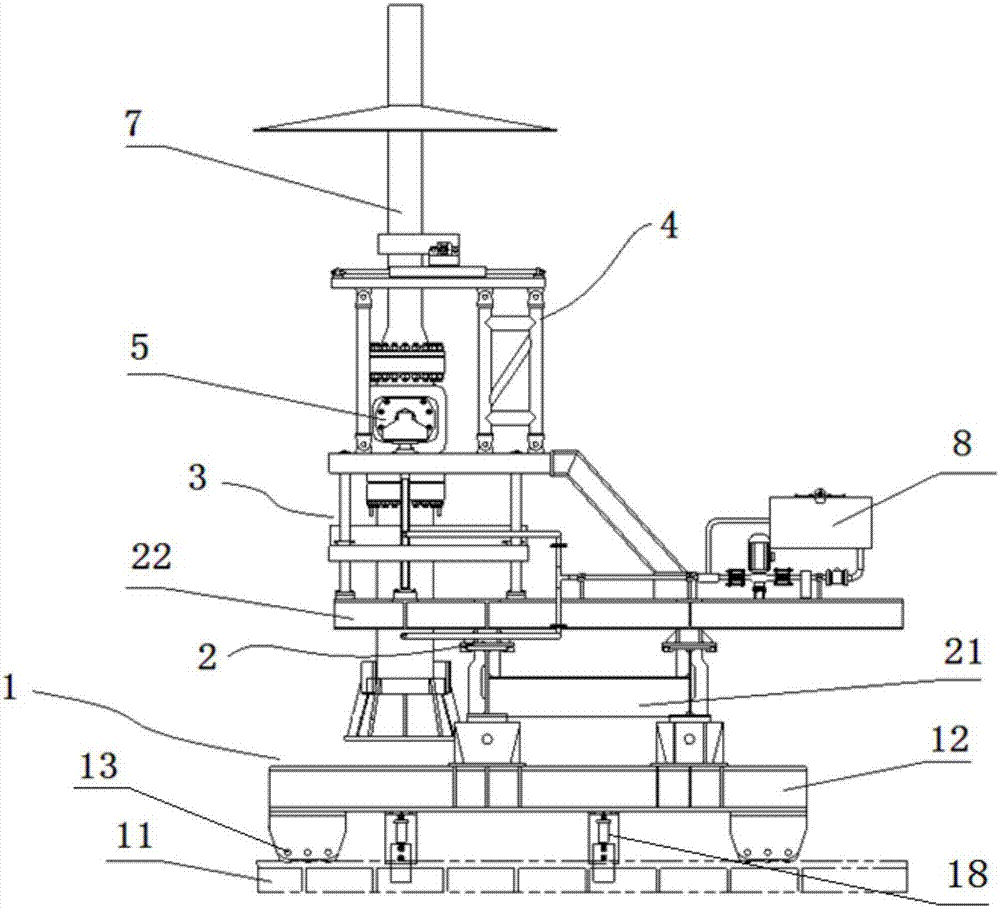

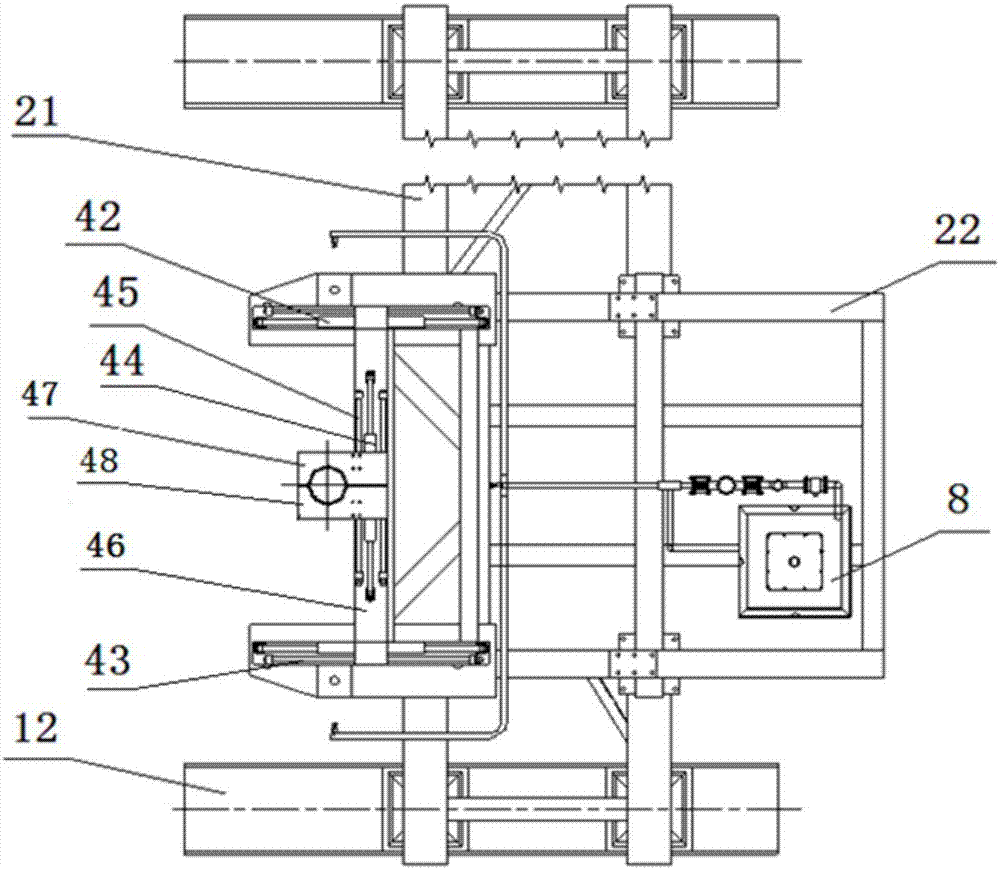

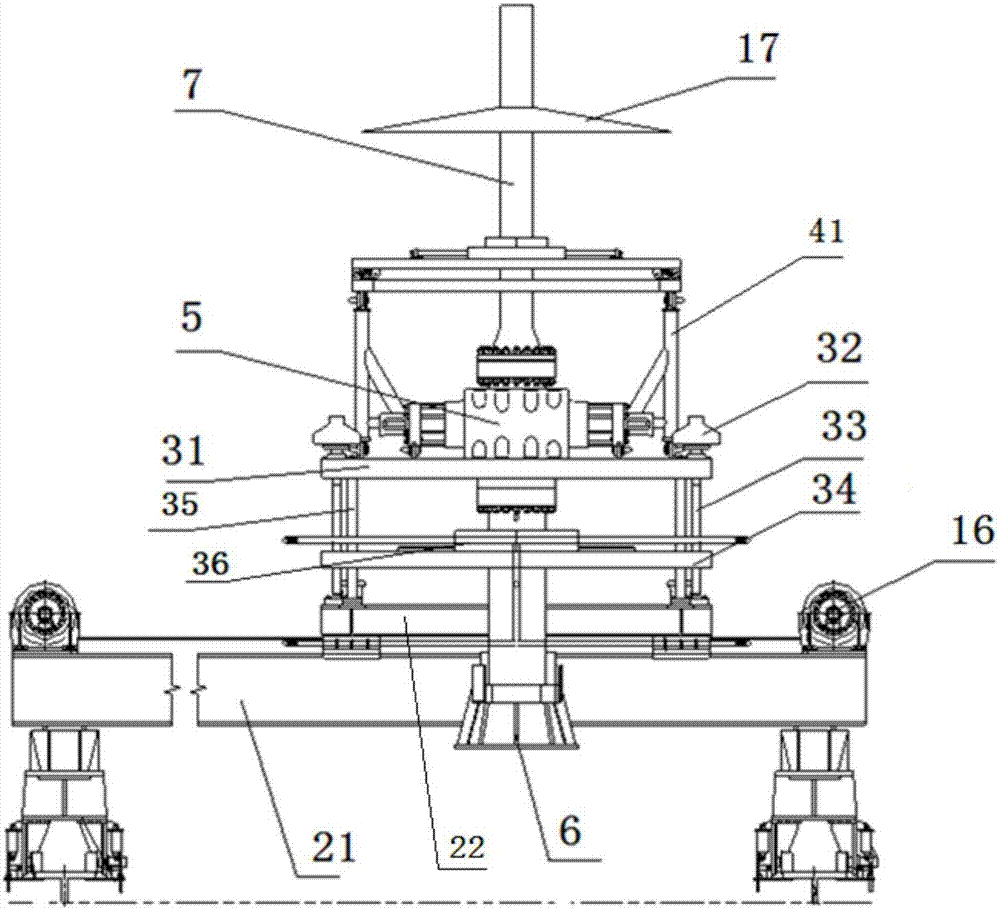

[0020] Such as Figure 1~4 As shown, the present invention provides a self-propelled offshore wellhead operation device, which includes a sliding system, a wellhead centering mechanism and a cooling system;

[0021] The sliding system includes an X-direction sliding system 1 and a Y-direction sliding system 2. The X-direction sliding system 1 includes a platform slide rail 11, a sliding leg 12 and a sliding mechanism 13. The platform slide rails located on both sides of the wellhead 11 are provided with sliding legs 12 respectively, and the sliding legs 12 are slidably connected to the platform slide rail 11 through the sliding mechanism 13; the Y-direction sliding system 2 includes a support 21 and a base 22, and the support 21 overlaps the On the sliding leg 12, the base 22 slides along the length direction of the support 21 and is connected above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com