Wood-burning granule furnace

A pellet and wood-burning technology, applied in the field of intelligent wood-burning pellet stoves, can solve the problems of unstable hot air flow, inability to estimate and evaluate the long-term use of fuel, and easy failure and misjudgment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

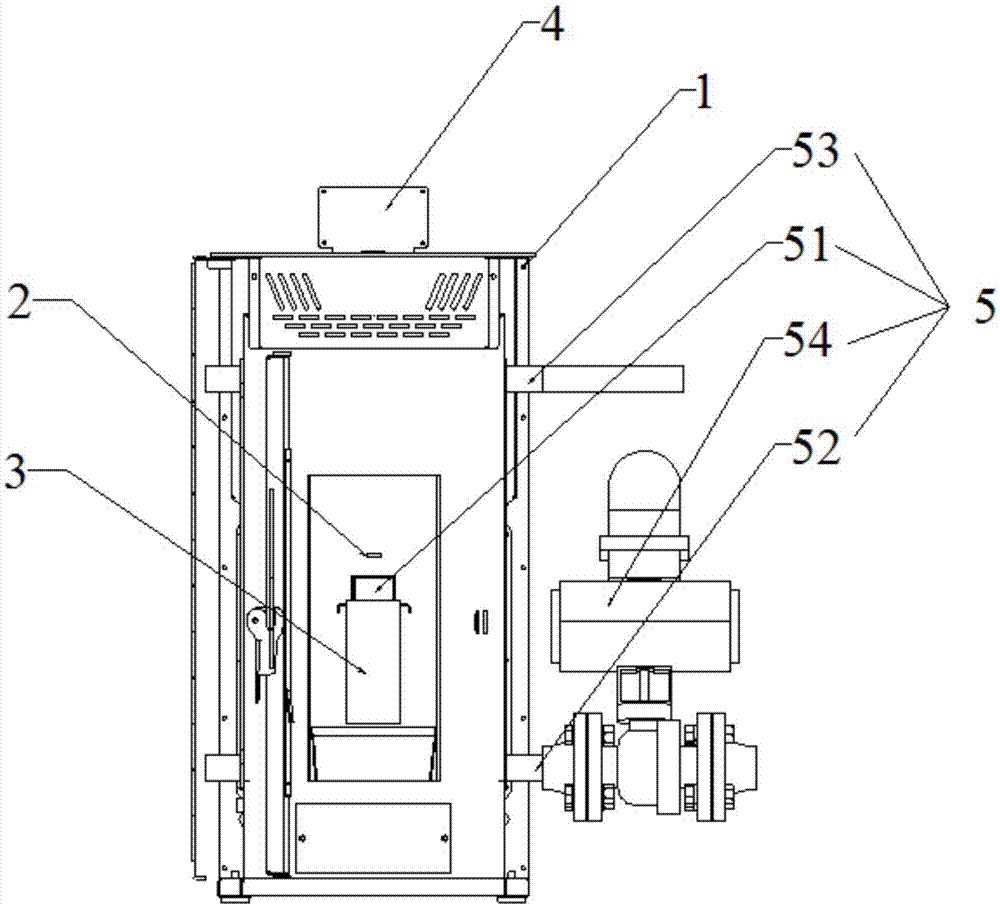

[0077] like figure 1 As shown, the present invention provides a wood-burning pellet stove, comprising:

[0078] Feeding device 2: set inside the casing 1, including a hopper 21 fixed on the upper part of the inside of the casing 1 and a conveyor belt 22 arranged directly below the hopper 21, a charging cover 23 is provided above the hopper 21, and a feeding cover 23 is provided at the bottom of the hopper 21. There is a switch 24; Figure 13 As shown, the conveyor belt 22 includes a first conveying area 221, a second conveying area 222 and a third conveying area 223 connected in sequence, the first conveying area 221 is arranged horizontally, and its entrance is located directly below the outlet of the hopper 21, The second transmission area 222 and the first transmission area 221 are set at an angle of 135-160°, the third transmission area 223 and the second transmission area 222 are set at an angle of 90-120°, and the second transmission area 222 and the third transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com