An intelligent control system for wood-burning pellet stove

An intelligent control system, particle technology, applied in the direction of combustion control, household stove/stove, combustion method, etc., can solve problems such as breakdown, wrong judgment of residual material, insufficient torque, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

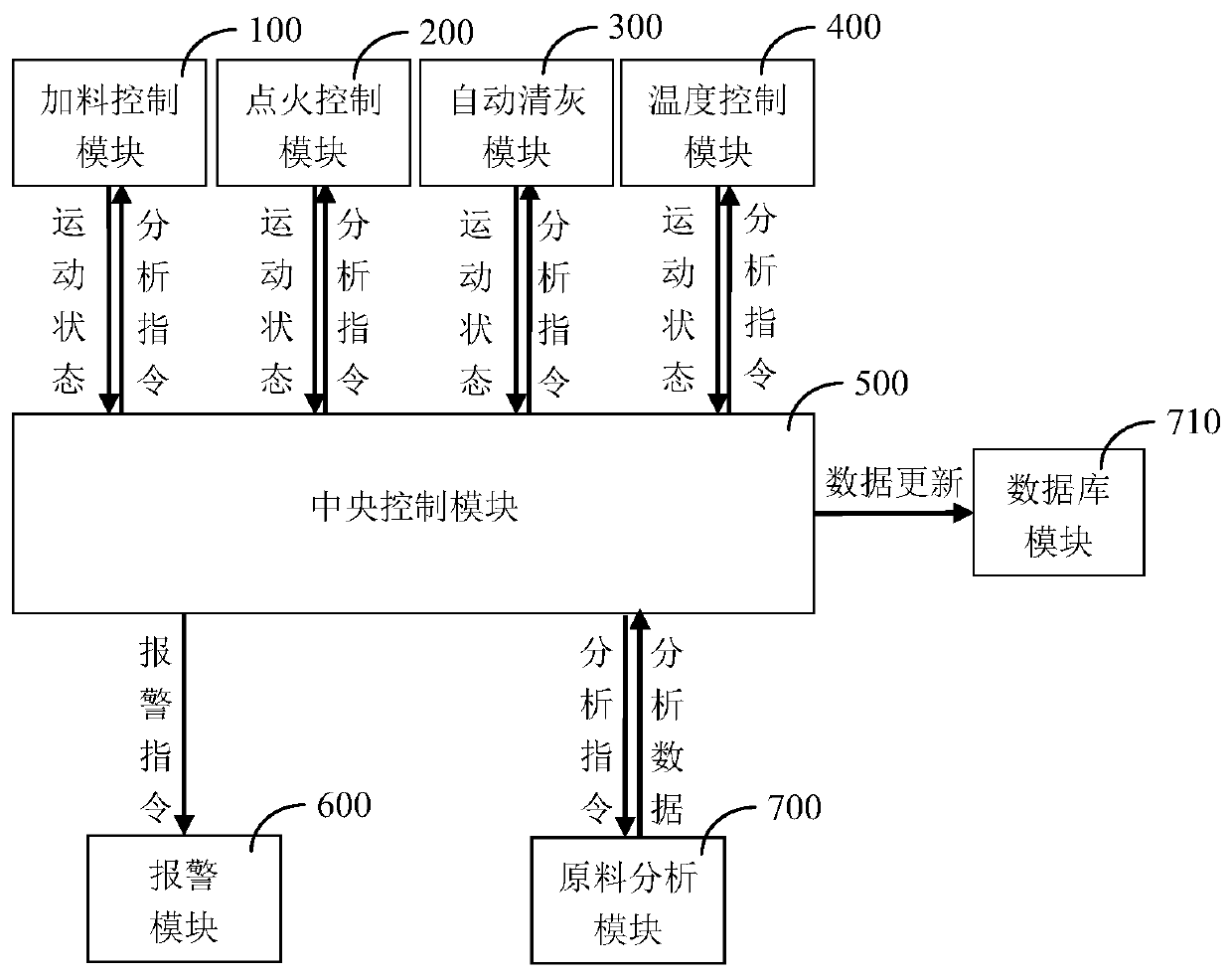

[0080] Such as figure 1 As shown, the present invention provides an intelligent control system for a wood-burning pellet stove, comprising:

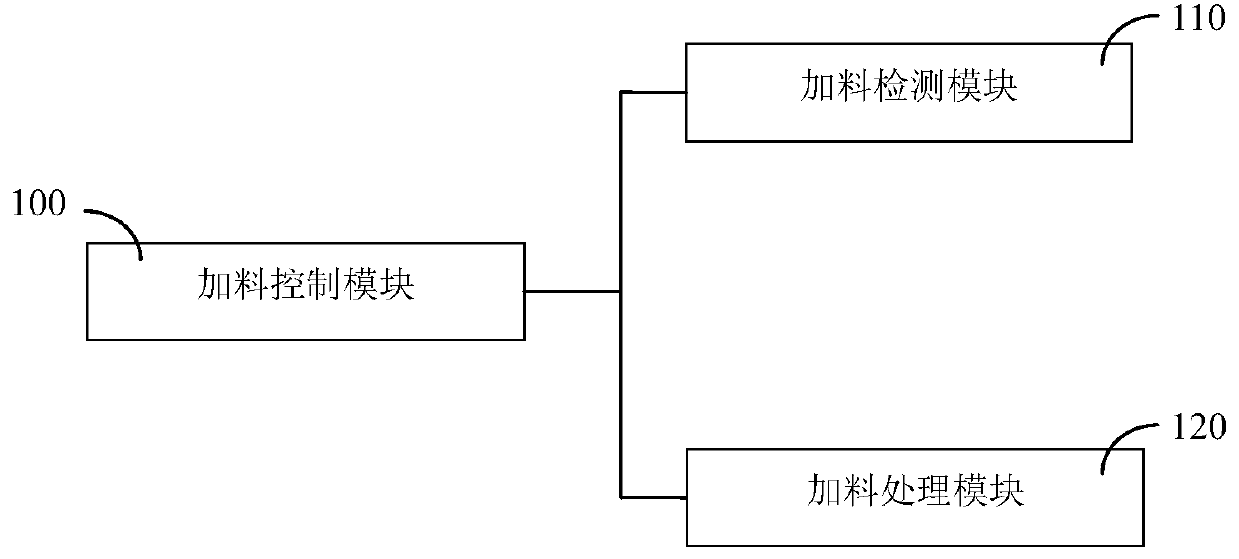

[0081] Feeding control module 100: used to detect the residual amount of wood pellet raw materials in the combustion chamber 21 and generate raw material residual information, used to control the operation of the feeding device according to the raw material residual information, and used to transmit the operating status data of the feeding device to the central The control module 500 is used to receive the raw material control instruction sent by the central control module 500; figure 2 As shown, further includes:

[0082] Feeding detection module 110: used to detect the remaining amount of wood pellet raw materials in the combustion chamber 21 and generate raw material residue information, and transmit the raw material residue information to the feeding processing module 120; the feeding detection module 110 uses a weighing sensor;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com