Composite activated iron tailing sand auxiliary cementing material and preparation method thereof

A technology for assisting cementitious materials and iron tailings sand, applied in cement production and other directions, can solve the problems of single process, low efficiency and poor activation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

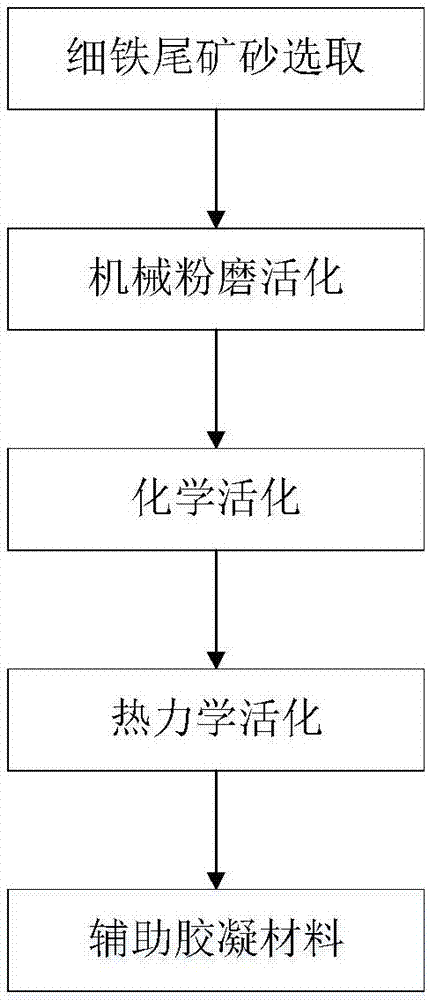

[0026] A preparation method for composite activated iron tailings auxiliary cementitious material, comprising the following steps,

[0027] Step 1. Selection of fine iron tailings: select SiO 2 Iron tailings with a content of 65% to 85% are screened with a square hole sieve, and fine iron tailings with a particle size of 0.075mm to 0.6mm are selected as activation targets to prepare auxiliary cementitious materials;

[0028] Step 2, mechanical grinding and activation: using a cement ball mill, the ball-to-material ratio is 3:1 to 8:1, and the grinding time is 1h to 3h, mechanically grinding the iron tailings to obtain primary activated iron tailings;

[0029] Step 3, chemical activation: adding Na 2 SiO 3 or Na 2 CO 3 Alkali metal silicate or carbonate chemical additives for chemical activation, the blending ratio of chemical additives is 0.5% to 3% of the content of the primary activated iron tailings to obtain secondary activated iron tailings;

[0030] Step 4. Thermody...

Embodiment 2

[0033] Choose SiO 2 The iron tailings with a content of 65% to 85% are screened with a square hole sieve, and the fine iron tailings with a particle size of 0.075mm to 0.6mm are selected as the activation target. First, a cement ball mill is used for mechanical grinding. The ball-to-material ratio is 3:1, and the grinding time is 3 hours to obtain primary activated iron tailings; then add 2% Na in the primary activated iron tailings 2 CO 3 Carry out chemical activation to obtain secondary activated iron tailings; finally, mix the secondary activated iron tailings with slag powder at a ratio of 2:1, and continue thermal activation treatment at 750°C for 3 hours to obtain the final composite activated iron tailings sand auxiliary glue condensate material.

Embodiment 3

[0035] Choose SiO 2The iron tailings with a content of 65% to 85% are screened with a square hole sieve, and the fine iron tailings with a particle size of 0.075mm to 0.6mm are selected as the activation target. First, a cement ball mill is used for mechanical grinding. The ball-to-material ratio is 6:1, and the grinding time is 1.5 hours to obtain primary activated iron tailings; then add 1% Na in the primary activated iron tailings 2 SiO 3 Carry out chemical activation to obtain secondary activated iron tailings; finally, mix the secondary activated iron tailings with limestone powder at a ratio of 1:1, and continue thermal activation treatment at 600°C for 2.5 hours to obtain the final composite activated iron tailings auxiliary sand gelling material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com