Tire assembly static and couple balance deviation compensation identifier oil supply device

A technology of force couple balance and supply device, which is applied in mechanical equipment, engine components, engine lubrication, etc., can solve the problems of difficult installation and use, difficult flow, uneven grease in the balancing machine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

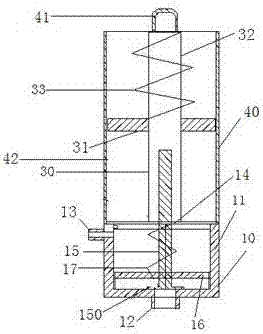

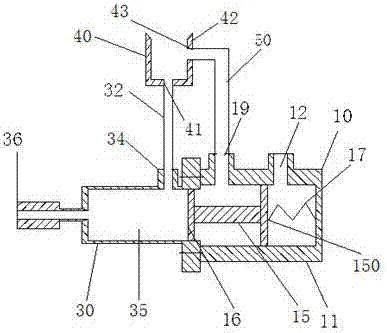

[0021] see figure 2 , the tire assembly static and force couple balance deviation compensation mark fuel supply device of the present invention includes an oil tank 40 with an oil tank cavity 42 provided with a discharge port 41, a cavity 11 containing a power supply pump, and an air inlet 12 , piston ring 150, piston rod 15, piston 16 and return spring 17 of the feed power pump 10, and a feed mechanism 30 comprising an oil delivery pipe 32. Depend on figure 2 It can be seen that the oil tank cavity 42 of the oil tank 40 is equipped with an oil agent (not shown in the figure), which is a separate structure from the feed power pump cavity 11 of the feed power pump 10, and the oil tank cavity 42 The discharge port 41 is located at the lower end of the oil tank cavity 42, the left end of the feed power pump cavity 11 of the feed power pump 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com