Trench gate RC-IGBT and preparation method thereof

A trench gate and trench technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as large reverse recovery peak current, reduced device conduction voltage drop, and uneven current distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

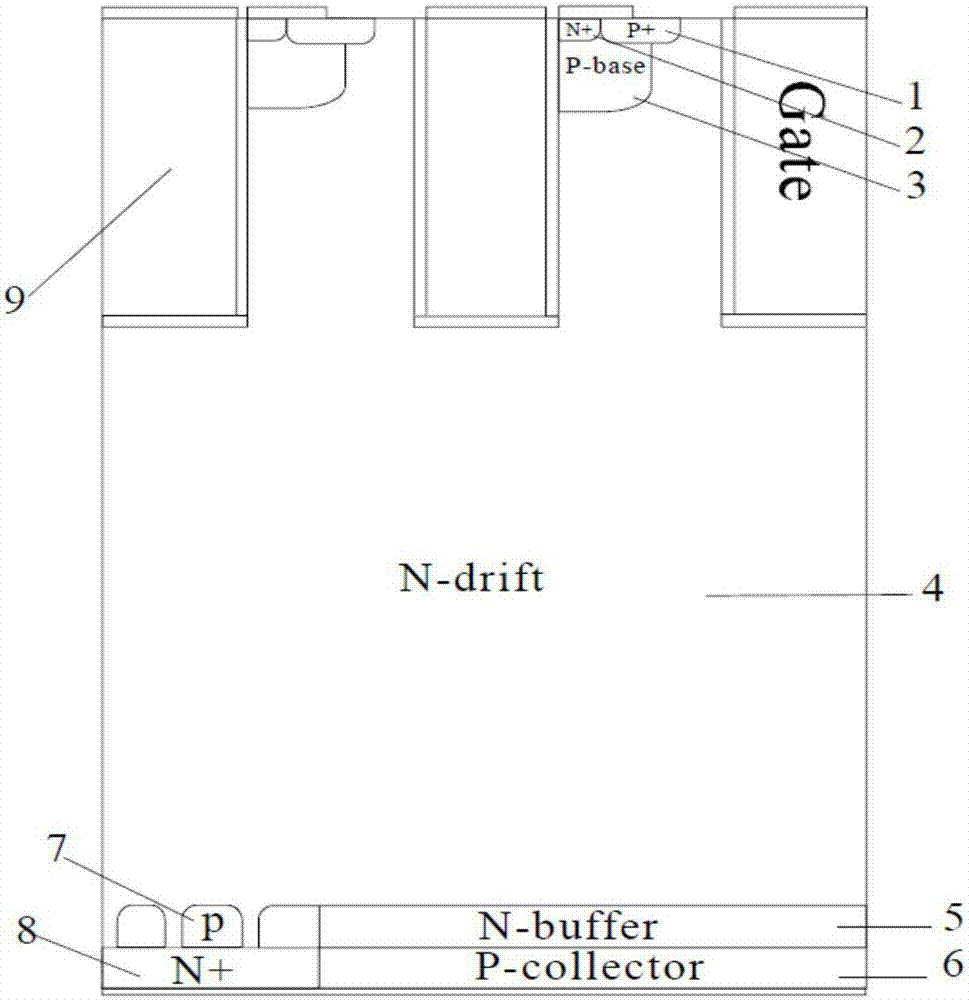

[0070] The present invention provides a trench gate RC-IGBT, such as image 3 shown, including N set sequentially from top to bottom + Emitter 2, P-base area 3, N - Layer 4, the upper surface of P-base area 3 is also provided with P + Emitter 1, P + Emitter 1 and N + Transmitters 2 arranged side by side, N - Several grooves 9 are etched on the upper surface of layer 4, and SiO 2 Gate Oxide, SiO 2 A polysilicon gate is deposited on the gate oxide layer, P + Emitter 1, N + The emitter 2 and the P-base region 3 are located on the same side of the trench 9, and the N + The side walls of the emitter 2 and the P-base region 3 are all in contact with the outer surface of the side wall of the trench 9, N - The back of layer 4 is provided with N buffer layer 5, and the back of N buffer layer 5 is provided with P + Collector 6, P + One side...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Groove width | aaaaa | aaaaa |

| Groove depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com