Biaxial flexible photovoltaic tracking bracket

A flexible and photovoltaic technology, applied in the support structure of photovoltaic modules, photovoltaic modules, photovoltaic power generation, etc., can solve the problems of high cost, high cost, bearing maintenance, etc., and achieve the effect of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

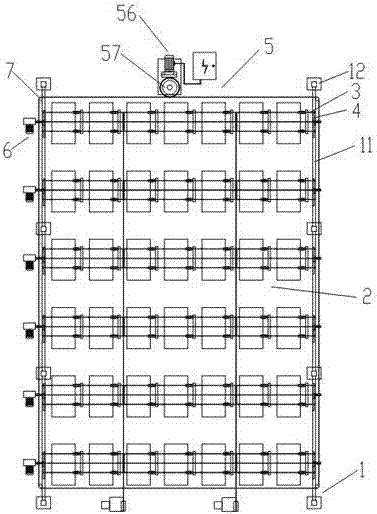

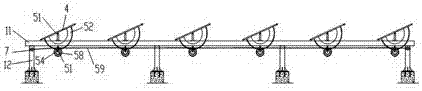

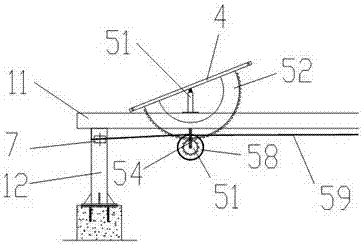

[0034] figure 1 , figure 2 and Figure 7 A specific embodiment of the present invention is shown: a biaxial flexible photovoltaic tracking bracket 1, including a bracket 1 body, the bracket 1 is used to install and fix solar panels 21, and the bracket 1 is horizontally equipped with multiple sets of solar panel groups 2, and the solar energy The battery panel group 2 is arranged on at least two steel wire ropes 3, and the two ends of the steel wire ropes 3 are provided with struts 4, and the struts 4 are turned over relative to the support 1 along the axis of the solar panel group 2, and the support 1 is provided with a driving strut 4 to rotate The overturning mechanism 5; the solar panel group 2 is composed of a plurality of solar panel groups, one end of the solar panel 21 is hinged relative to the steel wire rope 3, and the other end i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com