Thin multi-layer absorption core body and preparing method thereof

An absorbent core and multi-level technology, applied in the field of sanitary products, can solve the problems of the overall structure being too thick, not thin enough, destroying forest resources, etc., and achieve the effect of improving utilization rate, small weight and thin thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

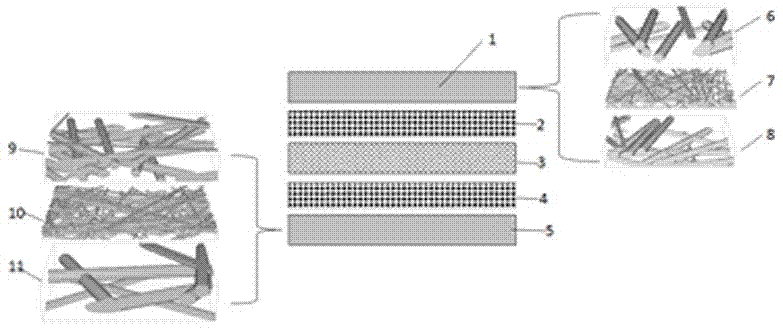

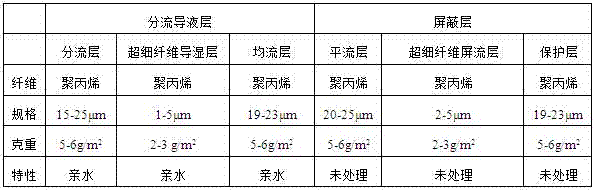

[0031] The fluffy fiber layer adopts 45g / m 2 The hot-air fluffy non-woven fabric, the first polymer absorption layer and the second polymer absorption layer are made of 20-mesh superabsorbent resin, and the shunt liquid-guiding layer and shielding layer are shown in Table 1.

[0032] Table 1

[0033]

[0034] Preparation steps:

[0035] 1. The polypropylene filament fiber layer prepared by the spunbond method, the polypropylene ultrafine fiber layer prepared by the melt blown method and the polypropylene filament fiber layer prepared by the spunbond method are stacked together in turn, and sent to the hot rolling mill for internal determination. Form multi-layer non-woven fabrics, the temperature of the upper roll of the hot rolling mill is 134 °C, and the temperature of the lower roll of the hot rolling mill is 131 °C;

[0036] 2. Use a glue spraying machine to spray 0.35 g / m on the fine fiber surface (equal flow layer) of the multi-level non-woven fabric after hydrophil...

Embodiment 2

[0041] The fluffy fiber layer adopts 45g / m 2 The hot air fluffy non-woven fabric, the first polymer absorption layer and the second polymer absorption layer adopt 25 mesh superabsorbent resin, and the shunt liquid guide layer and shielding layer are shown in Table 2.

[0042] Table 2

[0043]

[0044] Preparation steps:

[0045] 1. The polypropylene filament fiber layer prepared by the spun-bonding method, the polypropylene ultra-fine fiber layer prepared by the melt-blown method and the polypropylene filament fiber layer prepared by the spun-bonding method are stacked together, and sent to a hot rolling mill for shaping. Multi-layer non-woven fabric, the temperature of the upper roll of the hot rolling mill is 144°C, and the temperature of the lower roll of the hot rolling mill is 138°C;

[0046]2. The hydrophilic polypropylene filament fiber layer prepared by spunbonding the low-melt index hydrophilic masterbatch and the polypropylene masterbatch with a melt index of 35...

Embodiment example 3

[0052] The fluffy fiber layer adopts 45g / m 2 The hot-air fluffy non-woven fabric, the polymer layer adopts 23 mesh super absorbent resin, and the shunt liquid-guiding layer and shielding layer are shown in Table 3.

[0053] table 3

[0054]

[0055] Preparation steps:

[0056] 1. The polypropylene filament fiber layer prepared by the spunbond method, the polypropylene ultrafine fiber layer prepared by the melt blown method and the polypropylene filament fiber layer prepared by the spunbond method are stacked together in turn, and sent to the hot rolling mill for internal determination. Form multi-level non-woven fabrics, the temperature of the upper roll of the hot rolling mill is 139°, and the temperature of the lower roll of the hot rolling mill is 143°;

[0057] 2. The distribution layer (air-through non-woven fabric) prepared by the 35 μm low-melting point sheath-core fiber layer, the melt-blown polypropylene superfine fiber layer and the flow equalization layer (air-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com