Distiller and process of using same to extract fatty acids from vegetable pitch

A distiller and heater technology, applied in the chemical industry, can solve problems such as asphalt flow failure and heater failure, and achieve the effects of facilitating heat transfer, improving efficiency, and increasing heat exchange rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiments of the present invention will be described in detail below in conjunction with the drawings.

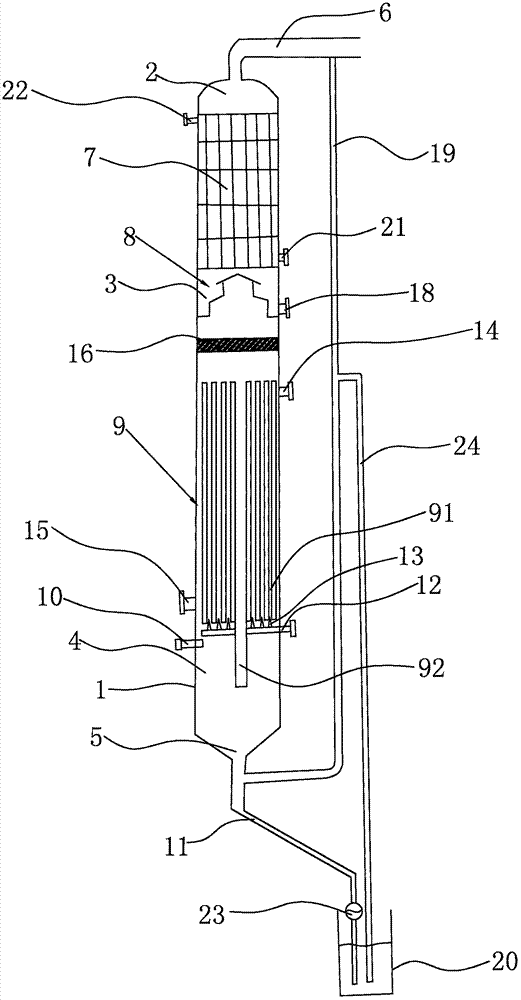

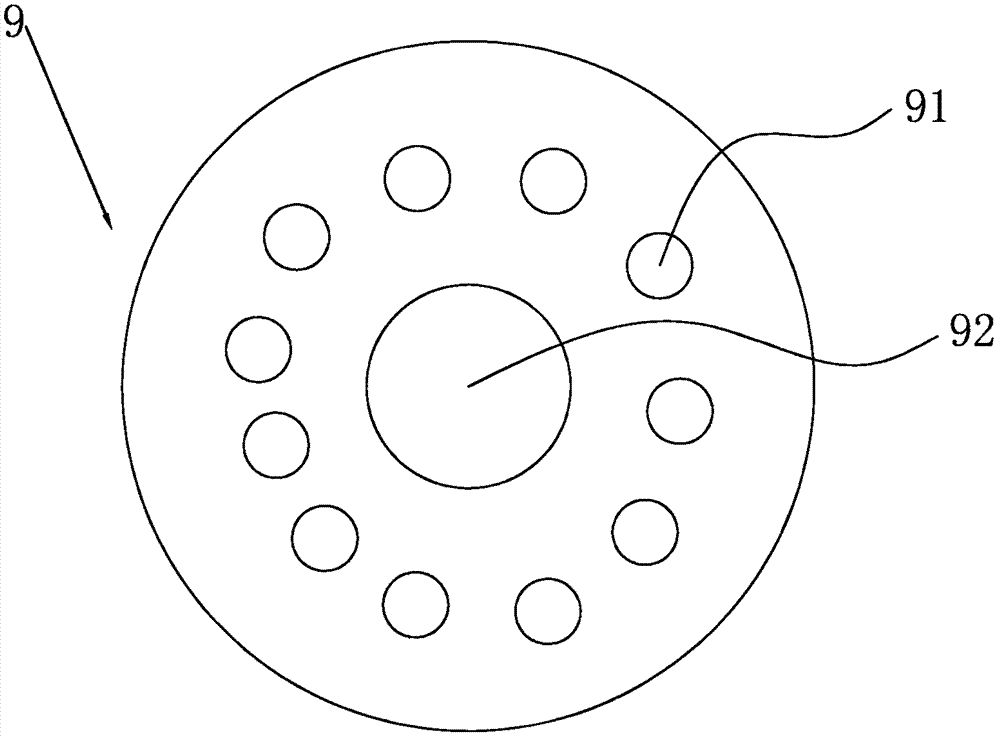

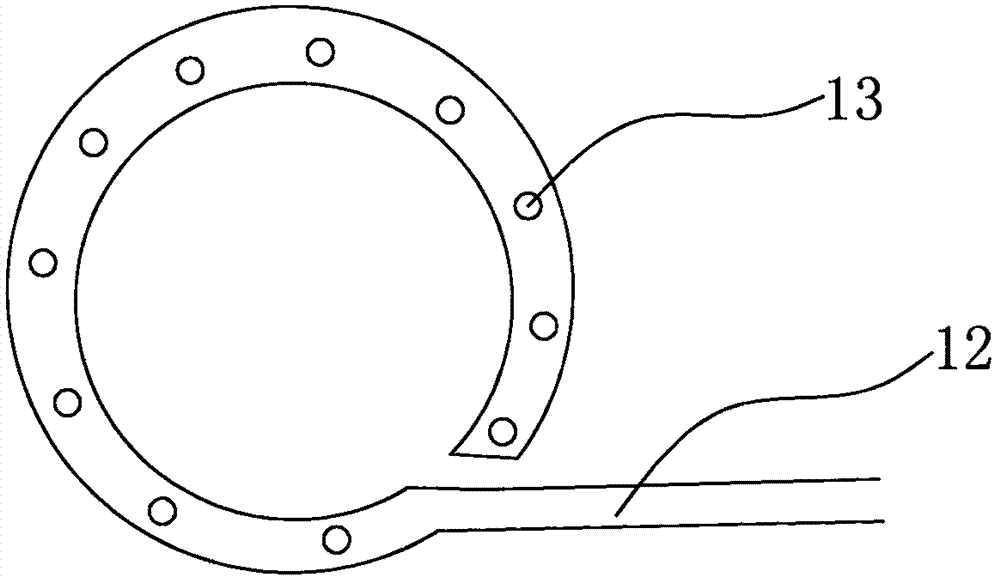

[0028] Such as Figure 1 ~ Figure 4 The shown steam vacuum distiller for extracting fatty acids from vegetable pitch includes a closed shell 1, which is roughly cylindrical. From top to bottom in the shell 1 are vacuuming zone 2, cooling zone (not marked on the figure), condensate recovery zone 3, evaporation zone (not marked on the figure), feeding zone 4, and discharging zone 5. The vacuuming zone 2 is located at the top of the shell 1, and a vacuum tube 6 is arranged on the top of the shell 1. The vacuum tube 6 is connected with an external vacuuming system, and the air pressure in the shell is evacuated to less than 2 mmHg through the vacuuming system. A condenser 7 is arranged in the cooling zone, and the condenser is used to condense the gas discharged from the evaporation zone. The condenser 7 is water-cooled. A cooling water inlet pipe 21 and a w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com