Automatic-zooming laser cleaning head device and cleaning method thereof

A technology of laser cleaning and automatic zooming, applied in cleaning methods and appliances, chemical instruments and methods, optics, etc., can solve problems such as failure to reach, uneven cleaning, and inhalation of metal dust by workers, and meet the requirements of reducing technical proficiency , Avoid poor cleaning effect and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

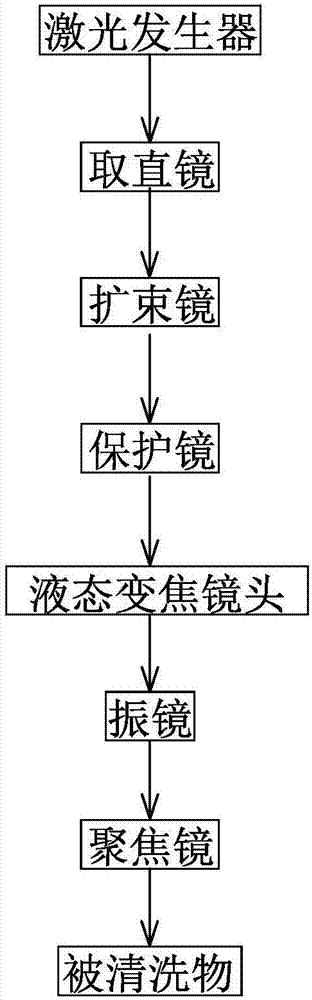

[0018] Such as figure 1 As shown in , an automatic zoom laser cleaning head device includes a laser generator, and the rear side of the laser generator is sequentially provided with a straightening mirror, a protective mirror and a vibrating mirror along the traveling direction of the beam. A beam expander is arranged between the mirrors, a liquid zoom lens is arranged between the protection mirror and the vibrating mirror, and a focusing mirror is arranged on the rear side of the vibrating mirror along the traveling direction of the light beam.

[0019] In the master's degree thesis of the Institute of Precision Engineering of Chung Hsing University published in July 1998 - the research on the value of the variable focus liquid lens module driven by low ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com