Preparation method of smooth porous surface of glass

A porous surface and glass surface technology, applied in the direction of coating, etc., can solve the problems of high cost and difficult operation of single-layer polystyrene microspheres, and achieve the effect of low cost, excellent liquid repellency and good self-cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

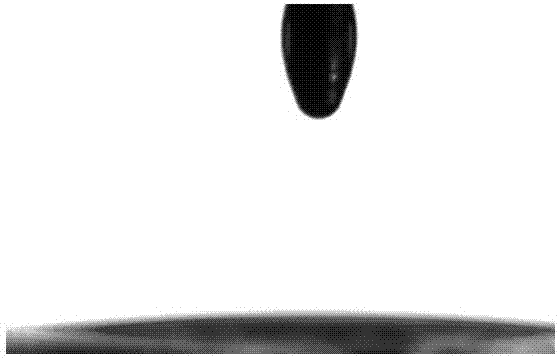

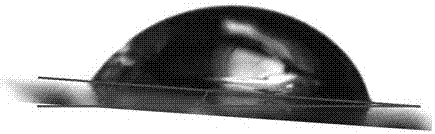

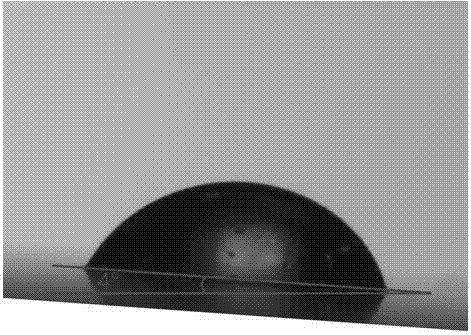

Image

Examples

Embodiment 1

[0021] Embodiment 1: a kind of preparation method of smooth porous surface of glass, concrete steps are:

[0022] (1) Pre-treatment: use 99% acetone and distilled water to clean the glass ultrasonically in order to remove dust and oil on the glass surface;

[0023] (2) Pretreatment: at a temperature of 80°C, place the pretreated glass in step (1) in a sodium hydroxide solution for 3 hours and take it out, then rinse it with distilled water, and dry it; the concentration of sodium hydroxide is 0.2mol / L; Sodium hydroxide solution etches a layer to multi-layer micro-nano structure on the glass surface;

[0024] (3) Surface modification: Soak the glass pretreated in step (2) in 1H,1H,2H,2H-perfluorodecyltriethoxysilane for 6 hours, take it out, and dry it;

[0025] (4) Pouring coating: Place the surface-modified glass in step (3) in a homogenizer, pour and coat the glass surface with a lubricating liquid (the lubricating liquid is perfluoropolyether lubricating oil) to obtain a ...

Embodiment 2

[0028] Embodiment 2: a kind of preparation method of smooth porous surface of glass, concrete steps are:

[0029] (1) Pre-treatment: use 99% acetone and distilled water to clean the glass ultrasonically in order to remove dust and oil on the glass surface;

[0030] (2) Pretreatment: At a temperature of 70°C, place the pretreated glass in step (1) in a sodium hydroxide solution for 9 hours and take it out, then rinse it with distilled water, and dry it; the concentration of sodium hydroxide is 0.15mol / L;

[0031] (3) Surface modification: Soak the glass pretreated in step (2) in 1H,1H,2H,2H-perfluorodecyltriethoxysilane for 7 hours, take it out, and dry it;

[0032] (4) Pouring coating: Place the surface-modified glass in step (3) in a homogenizer, pour and coat the glass surface with a lubricating liquid (the lubricating liquid is perfluoropolyether lubricating oil) to obtain a smooth porous surface of the glass, wherein The spin coating speed is 5000r / min;

[0033] The op...

Embodiment 3

[0034] Embodiment 3: a kind of preparation method of smooth porous surface of glass, concrete steps are:

[0035] (1) Pre-treatment: use 99% acetone and distilled water to clean the glass ultrasonically in order to remove dust and oil on the glass surface;

[0036] (2) Pretreatment: at a temperature of 60°C, place the pretreated glass in step (1) in a sodium hydroxide solution for 15 hours and take it out, then rinse it with distilled water, and dry it; the concentration of sodium hydroxide is 0.1mol / L;

[0037] (3) Surface modification: Soak the glass pretreated in step (2) in 1H,1H,2H,2H-perfluorodecyltriethoxysilane for 8 hours, take it out, and dry it;

[0038] (4) Pouring coating: Place the surface-modified glass in step (3) in a homogenizer, pour and coat the glass surface with a lubricating liquid (the lubricating liquid is perfluoropolyether lubricating oil) to obtain a smooth porous surface of the glass, wherein The spin coating speed is 6000r / min;

[0039] The op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com