Composition with open cell ceramics for 3D printing preparation and using method thereof

A technology of 3D printing and microporous ceramics, applied in the field of 3D printing materials, can solve the problem of not being able to obtain ceramics with open micropores, and achieve the effects of good market application prospects, low manufacturing costs, and simple preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following specific examples will be used to further describe the present invention in detail, but should not be construed as any limitation to the protection content of the present invention.

[0029] 1. Preparation of a composition with open microporous ceramics for 3D printing

[0030] Preparation of ceramic slurry A for 3D printing: Ceramic powder, water, dispersant, binder, unsaturated ethylenic monomer, polyene crosslinking agent, and ammonium persulfate are respectively 20-60%, 20- 60%, 0.2%-4%, 0.5%-10%, 3%-20%, 0.1-4% and 0.1-2% are prepared as ceramic slurry A for 3D printing.

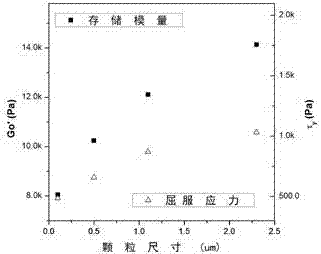

[0031] According to the change of the proportion of different raw materials in the ceramic slurry A for 3D printing of the present invention, the properties of the ceramic slurry A for 3D printing will have certain changes, and the specific changes are mainly from the fluidity of the printable ceramic slurry A and the printability of the ceramic slurry A. The formability of the cer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com