Continuous production device of powdered and granulated polyphosphate fertilizer

A technology of polyphosphate and production equipment, which is applied in the direction of magnesium bisphosphate fertilizer, alkaline orthophosphate fertilizer, magnesium phosphate fertilizer, etc. It can solve the problems that are not conducive to continuous product extraction and cannot achieve continuous large-scale production. , to achieve the effect of overcoming the difficulty of continuous discharge, large production capacity and strong chelating ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

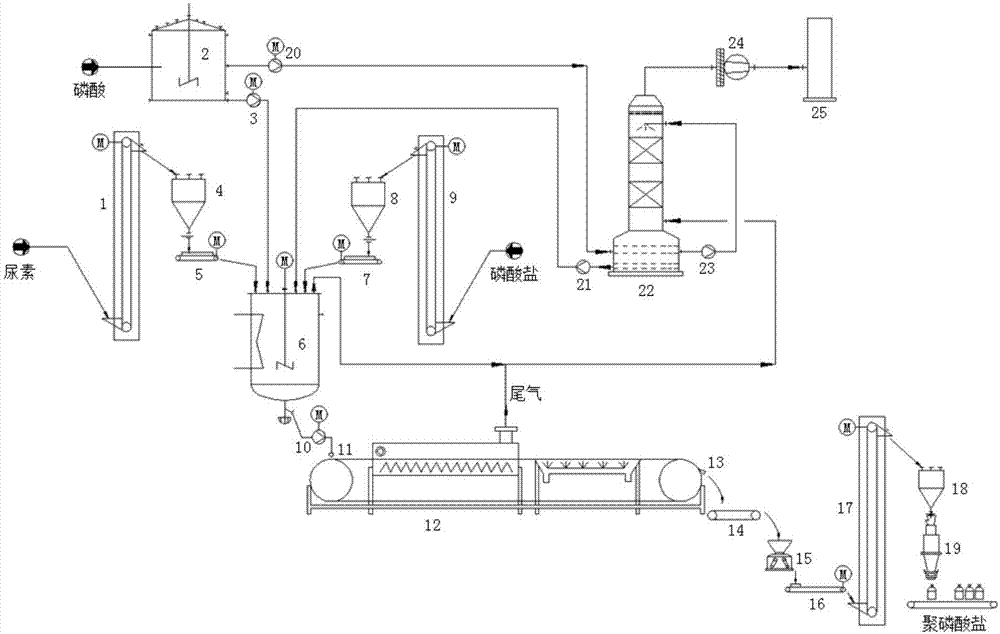

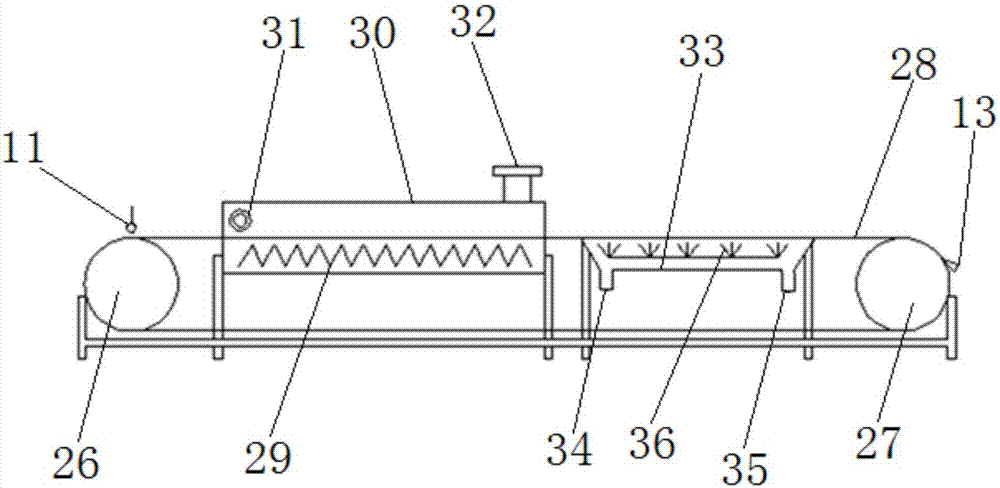

[0042] like figure 1 A continuous production device for powdery polyphosphate fertilizer shown, the device includes a urea delivery unit, a phosphoric acid delivery unit, a phosphate delivery unit, and a pre-loading unit connected to the urea delivery unit, the phosphoric acid delivery unit and the phosphate delivery unit respectively. The polymerizer 6, the belt polymerizer 12 connected to the prepolymerizer 6, the tail gas treatment unit and the post-treatment unit connected to the prepolymerizer 6 and the belt polymerizer 12 respectively, are composed of a urea delivery unit and a phosphoric acid delivery unit respectively. , urea, phosphoric acid, and phosphate transported by the phosphate delivery unit are mixed in the prepolymerizer 6 and prepolymerized to obtain a fluid viscous material, which is sequentially heated, polymerized, and cooled in the belt polymerizer 12 solidified, and then crushed in the post-processing unit to obtain powdery polyphosphate fertilizer.

...

Embodiment 2

[0054] Utilize the concrete steps of device continuous production powdery potassium polyphosphate fertilizer in embodiment 1 to be:

[0055] 1) Pre-polymerization: Add phosphoric acid, potassium dihydrogen phosphate and urea to the pre-polymerizer 6 respectively, and react at 60°C for 10 minutes to obtain a viscous material with proper fluidity;

[0056] 2) thermal polymerization and cooling: adding the viscous material to the belt polymerizer 12 equipped with a heating zone and a cooling zone at a uniform speed, and then heating, polymerizing, cooling and solidifying in sequence to obtain a solid material;

[0057] 3) Crushing: After the solid material is broken, powdery potassium polyphosphate fertilizer can be obtained.

Embodiment 3

[0059] Utilize the concrete steps of device continuous production powder calcium polyphosphate fertilizer in embodiment 1 to be:

[0060] 1) Pre-polymerization: Add phosphoric acid, calcium dihydrogen phosphate and urea to the pre-polymerizer 6 respectively, and react at 140°C for 2 minutes to obtain a viscous material with proper fluidity;

[0061] 2) thermal polymerization and cooling: adding the viscous material to the belt polymerizer 12 equipped with a heating zone and a cooling zone at a uniform speed, and then heating, polymerizing, cooling and solidifying in sequence to obtain a solid material;

[0062] 3) Crushing: After the solid material is broken, powdery calcium polyphosphate fertilizer can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com