Gradient separation and comprehensive utilization method of active ingredient of puffball

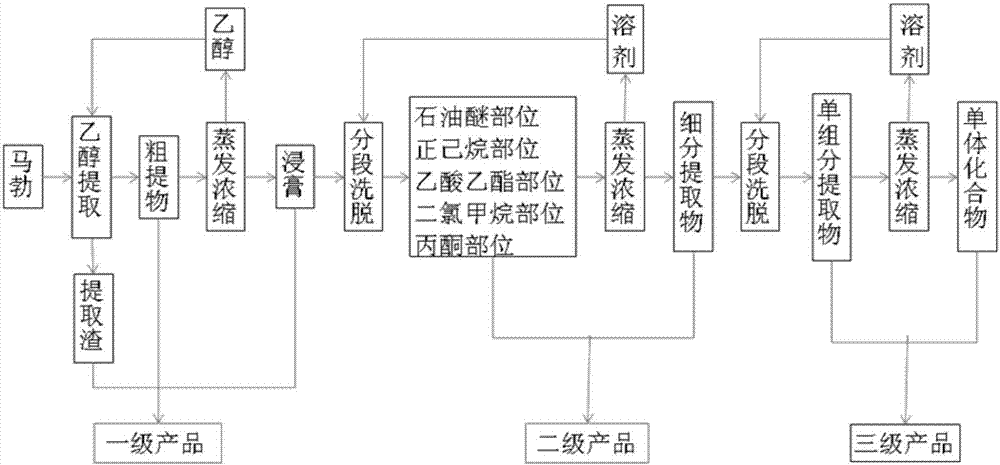

An active ingredient and gradient technology, which is applied in the field of gradient separation and comprehensive utilization of puffball active ingredients, can solve the problems of complex extraction process, high waste material and high comprehensive cost, and achieves high separation efficiency, high comprehensive benefit and simple preparation method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Put 132g of puffball into a 5L four-neck round bottom flask, add 2.6L of absolute ethanol, install a reflux condenser, a thermometer, mechanically stir, heat to 60°C under stirring, and keep the temperature for 2 hours. Suction filtration while hot, and repeat the above operation for the filter residue, and carry out the second and third extractions. The obtained filtrate was concentrated with a rotary evaporator to obtain 2.3 g of extract, and the evaporated solvent was recovered and recycled. After the filter residue is dried, the remaining 130g is used as organic fertilizer.

Embodiment 2

[0034] Put 277g of puffball into a 5L four-neck round bottom flask, add 2.8L of absolute ethanol, install a reflux condenser, a thermometer, mechanically stir, heat to 70°C under stirring, and keep the temperature for 2 hours. Suction filtration while hot, and repeat the above operation for the filter residue, and carry out the second and third extractions. The obtained filtrate was concentrated with a rotary evaporator to obtain 4.8 g of extract, and the evaporated solvent was recovered and recycled. After the filter residue is dried, the remaining 273g is used as organic fertilizer.

Embodiment 3

[0036] Put 219g of puffball into a 5L four-necked round bottom flask, add 4L of absolute ethanol, install a reflux condenser, a thermometer, mechanically stir, heat to 65°C under stirring, and keep the temperature for 2 hours. Suction filtration while hot, and repeat the above operation for the filter residue, and carry out the second and third extractions. The obtained filtrate was concentrated with a rotary evaporator to obtain 3.9 g of extract, and the evaporated solvent was recovered and recycled. After the filter residue is dried, the remaining 216g is used as organic fertilizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com