Solid propellant and preparation method and application thereof

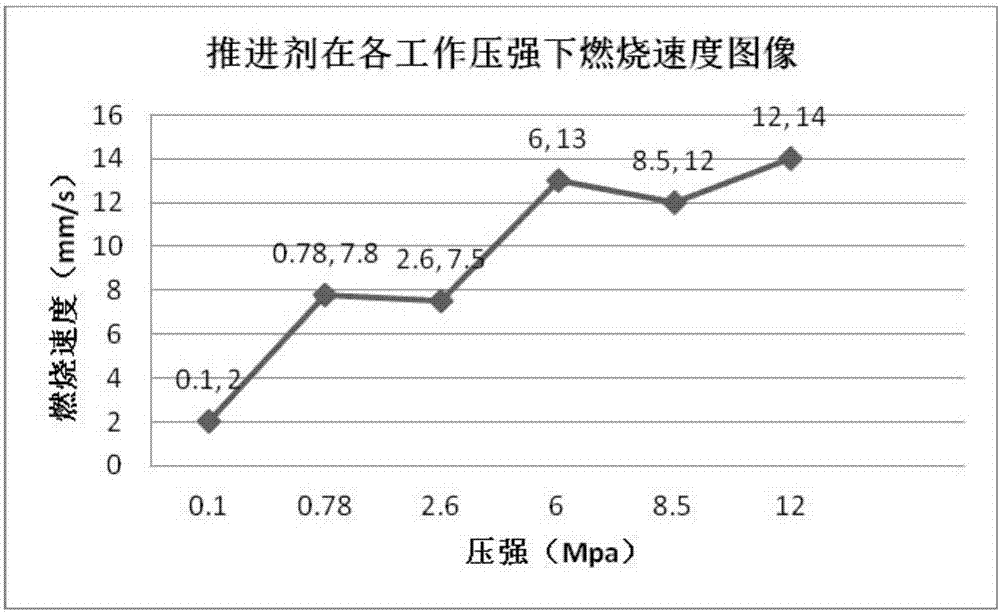

A solid propellant and reducing agent technology, which is applied in the direction of offensive equipment, compressed gas generation, non-explosive/non-thermal agent components, etc., can solve the problems of difficult preparation, high risk, high cost, etc., and achieve the preparation method The effect of safety and convenience, risk reduction and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

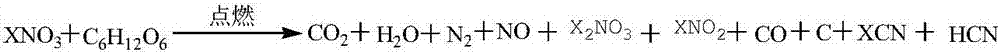

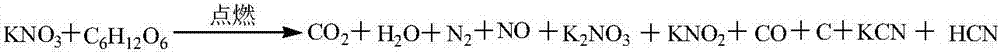

[0025] The solid propellant of the present embodiment is composed of the following mass percentage components: oxidant potassium nitrate: 62%, reducing agent glucose: 35%, particle diameter is 200 mesh catalyst ferric oxide powder: 2%, dehydrating agent stearic acid: 1 %.

[0026] The preparation method is: take solvent water with 30% glucose mass at room temperature, dissolve the glucose part in the water, heat the mixture at a constant temperature to 143°C, add potassium nitrate after the glucose is complete, stir well after adding the material, and keep the heating temperature until the water is completely Evaporate to dryness, add catalyst and dehydrating agent, stir well, then vacuum degas for 20 minutes to remove internal air bubbles, cool to 85°C, place in a mold and pressurize to 0.9MPa, open the mold when it is completely cooled to room temperature, and obtain a solid propellant .

[0027] The above-mentioned solid propellant is used as fuel for civilian small-sized ...

Embodiment 2

[0036] The solid propellant of the present embodiment is composed of the following mass percentage components: oxidant potassium nitrate: 61%, reducing agent glucose: 35%, particle diameter is 200 mesh catalyst ferric oxide powder: 3%, dehydrating agent stearic acid: 1 %.

[0037] The preparation method is: take solvent water with 30% glucose mass at room temperature, dissolve the glucose part in the water, heat the mixture at a constant temperature to 143°C, add potassium nitrate after the glucose is complete, stir well after adding the material, and keep the heating temperature until the water is completely Evaporate to dryness, add catalyst and dehydrating agent, stir well, then vacuum degas for 20 minutes to remove internal air bubbles, cool to 85°C, place in a mold and pressurize to 0.9MPa, open the mold when it is completely cooled to room temperature, and obtain a solid propellant .

[0038] The above-mentioned solid propellant is used as fuel for civilian small solid ...

Embodiment 3

[0042] The solid propellant of the present embodiment is composed of the following mass percentage components: oxidant potassium nitrate: 63%, reducing agent glucose: 35%, particle diameter is 200 mesh catalyst ferric oxide powder: 1%, dehydrating agent stearic acid: 1% %.

[0043] The preparation method is: take solvent water with 30% glucose mass at room temperature, dissolve the glucose part in the water, heat the mixture at a constant temperature to 143°C, add potassium nitrate after the glucose is complete, stir well after adding the material, and keep the heating temperature until the water is completely Evaporate to dryness, add catalyst and dehydrating agent, stir well, then vacuum degas for 20 minutes to remove internal air bubbles, cool to 85°C, place in a mold and pressurize to 0.9MPa, open the mold when it is completely cooled to room temperature, and obtain solid propulsion agent.

[0044] The above-mentioned solid propellant is used as fuel for civilian small so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com