A method for extracting 1-deoxynojirimycin from silkworm excrement

A technology of deoxynojirimycin and silkworm sand, applied in the direction of organic chemistry and the like, can solve problems such as unfavorable industrial production, high cost of raw materials, cumbersome process, etc., and achieves the benefits of large-scale industrial production, avoiding cumbersome and high costs, and fully and rationally utilizing The effect of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

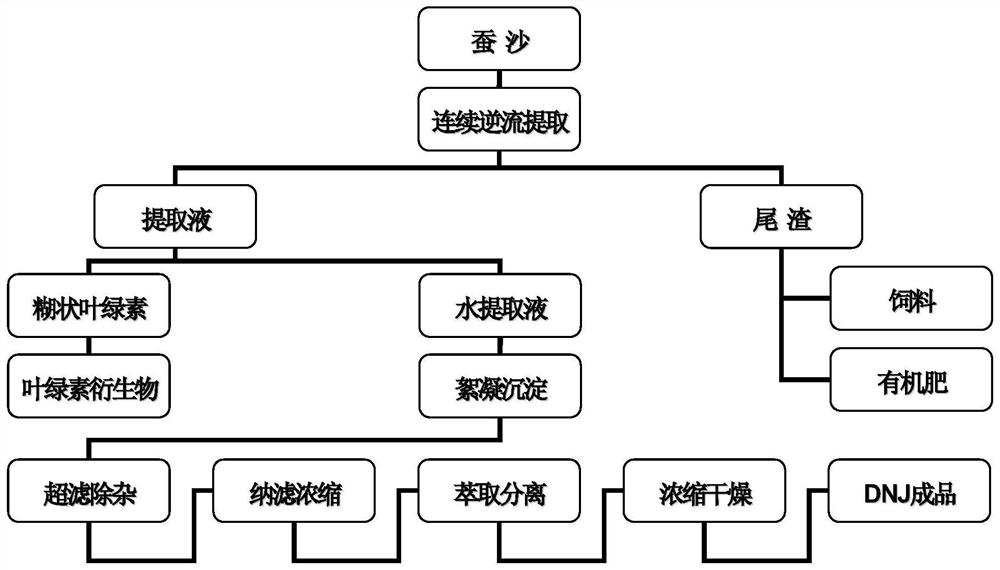

[0030] A method for the industrial production of 1-deoxynojirimycin by silkworm excrement, comprising the following steps:

[0031] a. Continuous countercurrent extraction: take a certain quality of silkworm excrement, dry cleaning, remove iron nails, stones, glass, dust, soil and other impurities, add water to moisten evenly, make the silkworm excrement moisture content 35%, enter continuous countercurrent Extractor, the temperature is controlled at 35-45 ° C, and the ethanol is continuously extracted in countercurrent for 1 hour to obtain the first extract, the first extract is concentrated under reduced pressure and the ethanol is recovered to obtain the second extract, and the second extract is cooled The silkworm excrement extract and the pasty mixture are separated and obtained, the pasty mixture is used for preparing chlorophyll derivatives, and the silkworm excrement extract is used for preparing 1-deoxynojirimycin.

[0032] b. Flocculation and precipitation: take 50 c...

Embodiment 2

[0038] A method for the industrial production of 1-deoxynojirimycin by silkworm excrement, comprising the following steps:

[0039] a. Continuous countercurrent extraction: take a certain quality of silkworm excrement, dry clean it, remove iron nails, stones, glass, dust, soil and other impurities, add water to moisten it evenly, make the silkworm excrement moisture content 45%, enter continuous countercurrent flow Extractor, the temperature is controlled at 35-45°C, and the ethanol is continuously extracted in countercurrent for 2 hours to obtain the first extract, the first extract is concentrated under reduced pressure and the ethanol is recovered to obtain the second extract, and the second extract is cooled The silkworm excrement extract and the pasty mixture are separated and obtained, the pasty mixture is used for preparing chlorophyll derivatives, and the silkworm excrement extract is used for preparing 1-deoxynojirimycin.

[0040]b. Flocculation and precipitation: tak...

Embodiment 3

[0046] A method for the industrial production of 1-deoxynojirimycin by silkworm excrement, comprising the following steps:

[0047] a. Continuous countercurrent extraction: Take a certain quality of silkworm excrement, dry clean it to remove iron nails, stones, glass, dust, soil and other impurities, add water to moisten it evenly, make the silkworm excrement moisture content 30%, and enter continuous countercurrent flow Extractor, the temperature is controlled at 35-45°C, and the ethanol is continuously extracted in countercurrent for 1.5 hours to obtain the first extract, the first extract is concentrated under reduced pressure and the ethanol is recovered to obtain the second extract, and the second extract is cooled The silkworm excrement extract and the pasty mixture are separated and obtained, the pasty mixture is used for preparing chlorophyll derivatives, and the silkworm excrement extract is used for preparing 1-deoxynojirimycin.

[0048] b. Flocculation and precipita...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com