Preparation method of q390kz anti-seismic hot-rolled h-shaped steel for steel structure

A Q390KZ, H-beam technology, applied in the field of metallurgical materials, can solve the problems of no seismic H-beam formulation and research, unable to fully check the deformation force mode, etc., to achieve strong economic and social benefits, small fluctuation range, good welding performance and the effect of low temperature impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

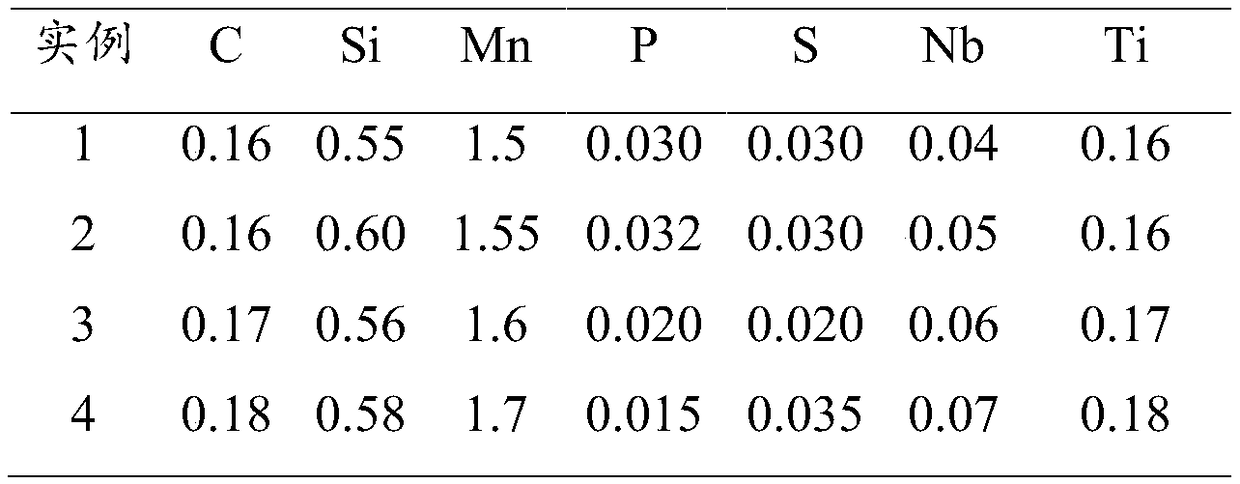

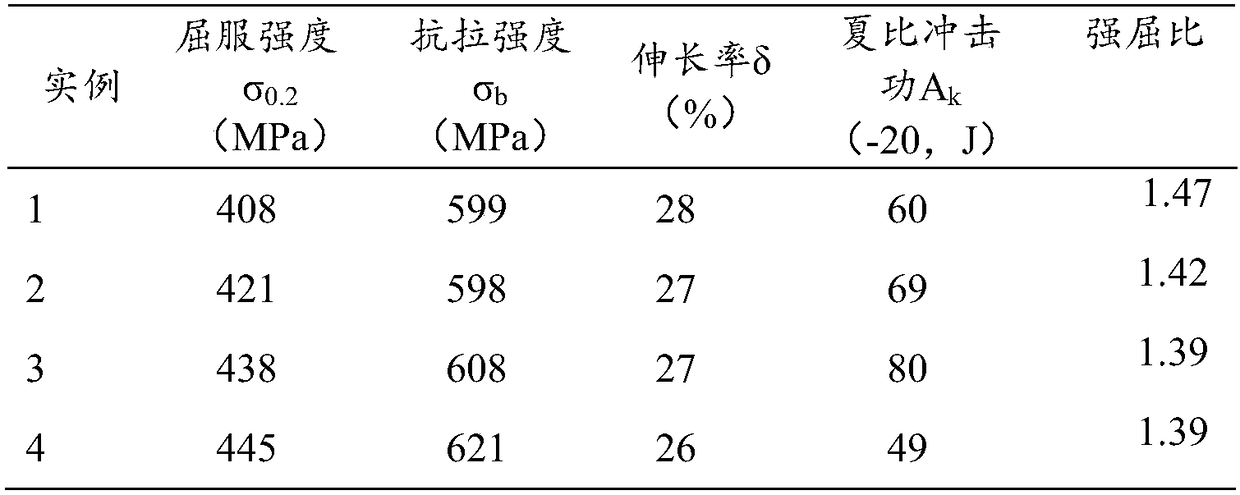

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be described in detail below with reference to exemplary implementations. Example embodiments may, however, be embodied in many forms and should not be construed as limited to the embodiments set forth herein; rather, these embodiments are provided so that this disclosure will be thorough and complete, and will fully convey the concept of example embodiments to those skilled in the art.

[0017] From the perspective of sustainable social development, the traditional production methods of brick-concrete and reinforced concrete structures can no longer meet the needs of building development, and the steel structure system has the advantages of facilitating the realization of standardization, componentization, industrialization, integration of production and operation, and energy saving. , water-saving, land-saving, material-saving, reusable and other characteristics, fully demonstrates the charm of "conservation-oriente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com