Combined steel bridge deck slab based on bonded steel fiber concrete and paving method of combined steel bridge deck slab

A technology of steel fiber concrete and steel bridge deck, which is applied in bridges, buildings, bridge parts, etc., can solve the problems of insufficient durability of orthotropic steel bridge deck pavement, achieve good combination effect and reduce thickness , The effect of reducing the amplitude of fatigue stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

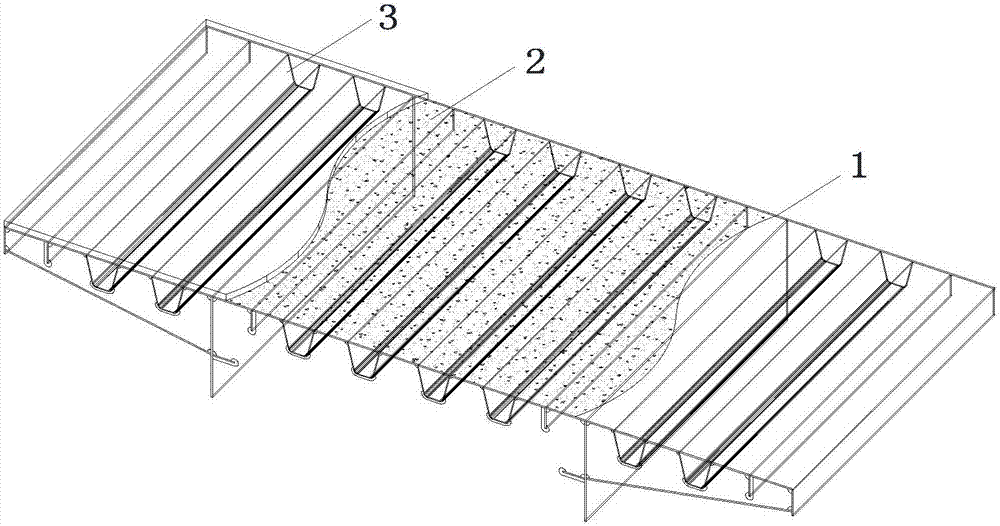

[0049] see figure 1 , The combined steel bridge deck based on bonded steel fiber concrete in this embodiment is composed of a steel cover plate 1, an adhesive layer 2, and an ultra-high performance steel fiber concrete 3. The thickness of the steel cover plate 1 of the present embodiment is 16mm, and the bonding layer 2 is made up of the epoxy resin glue layer and the silica sand embedded in the epoxy resin glue layer, and the thickness of the bonding layer 2 is 6mm. The resin glue is Sika 30 epoxy resin glue, and the silica sand with a particle size of 4-6mm is embedded in the 4mm epoxy resin glue layer to improve the friction coefficient of the bonding section and ensure the combination effect of the bonding layer 2. The bonding layer 2 is covered with cast-in-place ultra-high-performance steel fiber concrete 3 with a thickness of 35mm, so that the thickness ratio of the cover plate to the bonding layer 2 and the pavement layer of ultra-high-performance steel fiber concrete ...

Embodiment 2

[0072] The combined steel bridge deck based on bonded steel fiber concrete in this embodiment is composed of a steel cover plate 1 , an adhesive layer 2 , and an ultra-high performance steel fiber concrete 3 . The thickness of the steel cover plate 1 is the same as that of the first embodiment, and the composition and thickness of the bonding layer 2 are the same as those of the first embodiment. at 1m 3 The ultra-high performance steel fiber reinforced concrete 3 is composed of the following mass ratio materials:

[0073]

[0074] In the above proportions, the models and specifications of cement, silica fume, standard sand, steel fiber, and water reducer are the same as in Example 1.

[0075] The preparation method of ultra-high performance steel fiber reinforced concrete 3 is the same as that of Example 1.

[0076] The paving method is the same as in Example 1, and a composite steel bridge deck based on bonded steel fiber concrete is paved.

Embodiment 3

[0078] The combined steel bridge deck based on bonded steel fiber concrete in this embodiment is composed of a steel cover plate 1 , an adhesive layer 2 , and an ultra-high performance steel fiber concrete 3 . The thickness of the steel cover plate 1 is the same as that of the first embodiment, and the composition and thickness of the bonding layer 2 are the same as those of the first embodiment. at 1m 3 The ultra-high performance steel fiber reinforced concrete 3 is composed of the following mass ratio materials:

[0079]

[0080] In the above proportions, the models and specifications of cement, silica fume, standard sand, steel fiber, and water reducer are the same as in Example 1.

[0081] The preparation method of ultra-high performance steel fiber reinforced concrete 3 is the same as that of Example 1.

[0082] The paving method is the same as in Example 1, and a composite steel bridge deck based on bonded steel fiber concrete is paved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com