Blasting type building fireproof composite panel

A composite board and construction technology, which is applied in the field of building composite boards, can solve the problems of being unable to effectively extinguish fires, and achieve the effects of avoiding blockage, avoiding deliquescence, and increasing air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

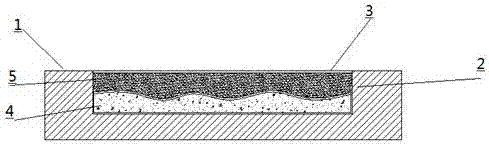

[0016] This embodiment provides a fire-proof composite panel for blasting buildings, which includes a body 1, a housing chamber 2 is provided in the body 1, and an air outlet 21 is opened on the top of the housing chamber 2, and the air outlet 21 is covered with a metal cover sheet 3 ; The bottom of the accommodation chamber 2 is provided with an expansion bag 4 wrapped with latex film, and the expansion bag 4 is filled with sodium bicarbonate powder; between the expansion bag 4 and the cover plate 3 is filled with an ABC fire extinguishing dry powder layer 5 .

[0017] Further, the cover sheet is embedded in the accommodation cavity; the cover sheet is in interference fit with the accommodation cavity.

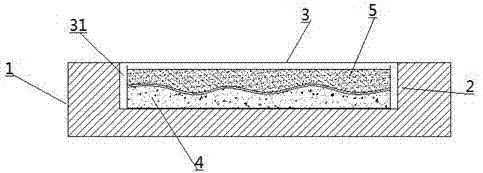

[0018] In another embodiment, such as figure 2 A plurality of metal conductive sheets 31 extend from the inner side of the cover sheet, and the conductive sheets 51 are wedged between the expansion bag 4 and the accommodating cavity 2 . In this embodiment, the conductive sh...

Embodiment 2

[0020] This embodiment provides a fireproof composite board for a blasting building, the structure of which is consistent with that of Embodiment 1.

[0021] In particular, the accommodating cavity of this embodiment is also filled with superabsorbent resin powder and activated carbon powder, and the mass ratio of superabsorbent resin, activated carbon powder and sodium bicarbonate powder is 0.2:1:7. In this embodiment, the superabsorbent resin powder is an acrylate superabsorbent resin.

Embodiment 3

[0023] This embodiment provides a fireproof composite board for a blasting building, the structure of which is consistent with that of Embodiment 2. Particularly, the accommodating cavity described in the present embodiment is also filled with a stabilizer, and the stabilizer includes 4 parts of nano-gold rods and 13 parts of nano-titanium dioxide by mass; the mass ratio of the stabilizer and sodium bicarbonate powder is 1: 700. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com