Tail gas particle purifier of diesel engine

A technology of exhaust particles and purifiers, which is applied in the direction of machines/engines, exhaust treatment, mechanical equipment, etc., can solve the problems of vehicle compressed air pressure drop, affect driving safety, and inconvenient debugging, and achieve convenient on-site debugging and accurate judgment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

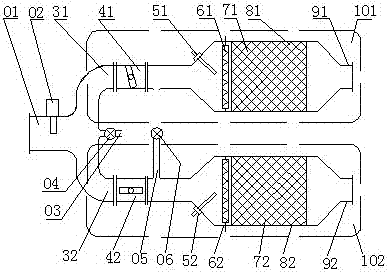

[0014] The embodiment of the diesel engine exhaust particulate purifier of the present invention will now be described in conjunction with the accompanying drawings. The exhaust particulate purifier includes an intake pipe 01 connected to the exhaust pipe of the diesel engine, and two sets of sub-purifiers 101 and 102 connected to the intake pipe 01. The device 101 includes a housing 81, one end of the housing is provided with a sub-intake pipe 31, and the other end of the housing is provided with an exhaust pipe 91. The sub-intake pipe 31 is equipped with a disc valve 41, and the housing A ceramic filter 71 for filtering exhaust gas particles is housed, an electric heater 61 for igniting particles is housed in front of the ceramic filter, and a temperature sensor 51 for measuring heating temperature is provided in front of the electric heater; the sub-purifier 102 includes a shell Body 82, sub-intake pipe 32, exhaust pipe 92, disc valve 42, ceramic filter 72, electric heater 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com