Ammonia gas automatic-supplying method of solid ammonia system heated by using engine waste heat

A heating method and engine technology, applied in engine components, combustion engines, machines/engines, etc., can solve problems such as the inability to meet large endurance, and achieve the effect of simple and easy heating solution, time saving, and improved continuation ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

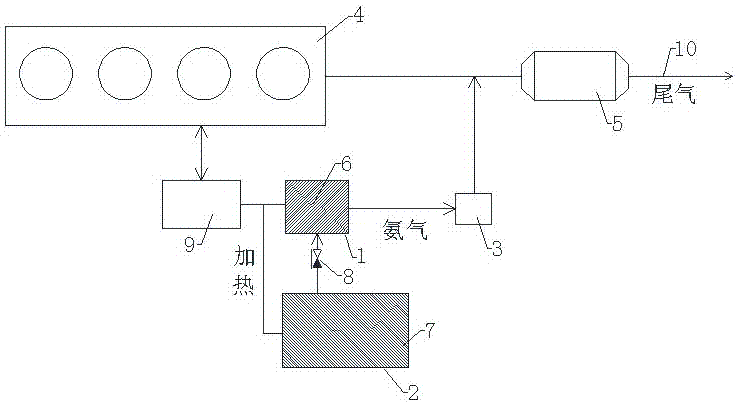

[0036] Use the exhaust gas of the engine to heat the main container 1 of the ammonia storage material, the exhaust temperature is usually between 150°C and 350°C, and the exhaust gas flow into the ammonia storage material container is controlled through one of the heating units 9—the exhaust gas three-way valve , heat the ammonia storage material 6 in the main container to desorb and release ammonia gas; control the pressure P1 in the main container 1 of the ammonia storage material to reach the working pressure between 1.2 and 3 bar; when P1 is greater than 1.2 bar, the reducing agent metering control unit DCU 3 according to the pressure The ammonia pressure value in the container detected by the sensor, after confirming that the state satisfies the working conditions, calculates the amount of ammonia gas required for emission treatment of NOx according to the engine operating parameters (speed, fuel consumption, etc.) transmitted by the engine ECU, and performs metered injecti...

Embodiment 2

[0042] Use the exhaust gas of the engine to heat the main container 1 of the ammonia storage material. The exhaust temperature is usually between 150°C and 350°C. The exhaust gas three-way valve is controlled by the heating unit 9 to control the flow of the exhaust gas into the ammonia storage material container, and the main heating The ammonia storage material 6 in the container desorbs and releases ammonia gas; the pressure P1 in the main container 1 of the ammonia storage material is controlled to reach the working pressure between 1.2 and 3 bar; when P1 is greater than 1.2 bar, the reducing agent metering control unit DCU3 The ammonia pressure value in the container, after confirming that the state meets the working conditions, calculates the amount of ammonia gas required to meet the emission and treatment of NOx according to the engine operating parameters (speed, fuel consumption, etc.) transmitted by the engine ECU, and injects the ammonia gas in a metered manner. The ...

Embodiment 3

[0047] like Figure 1-2 As shown, the ammonia storage material main container heating unit 9 uses a vehicle-mounted power supply electric heater to heat the ammonia storage material main container 1. When the heating temperature is higher than 50°C, the material in the ammonia storage material main container 1 begins to desorb after being heated. Release ammonia gas; the heating power is selected according to the size of the container, the power is between 200W~1000, and the heating temperature is controlled within 200°C, so that the ammonia storage material 6 in the main container of the ammonia storage material main container 1 releases ammonia gas quickly, and the ammonia gas in the container The pressure P1 reaches the controlled working pressure between 1.2 and 3bar; when P1 is greater than 1.2bar, the reducing agent metering control unit DCU3 confirms that the state meets the working conditions according to the ammonia pressure value in the container detected by the press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com