Rectangular substrate integrated waveguide sharing cavity-based duplexer

A substrate-integrated waveguide and rectangular cavity technology, which is applied to waveguide devices, circuits, electrical components, etc., can solve the problems that cannot meet the needs of communication frequency band expansion, low integration of duplexers, and large volume, and achieve an excellent choice performance, size reduction, and low insertion loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

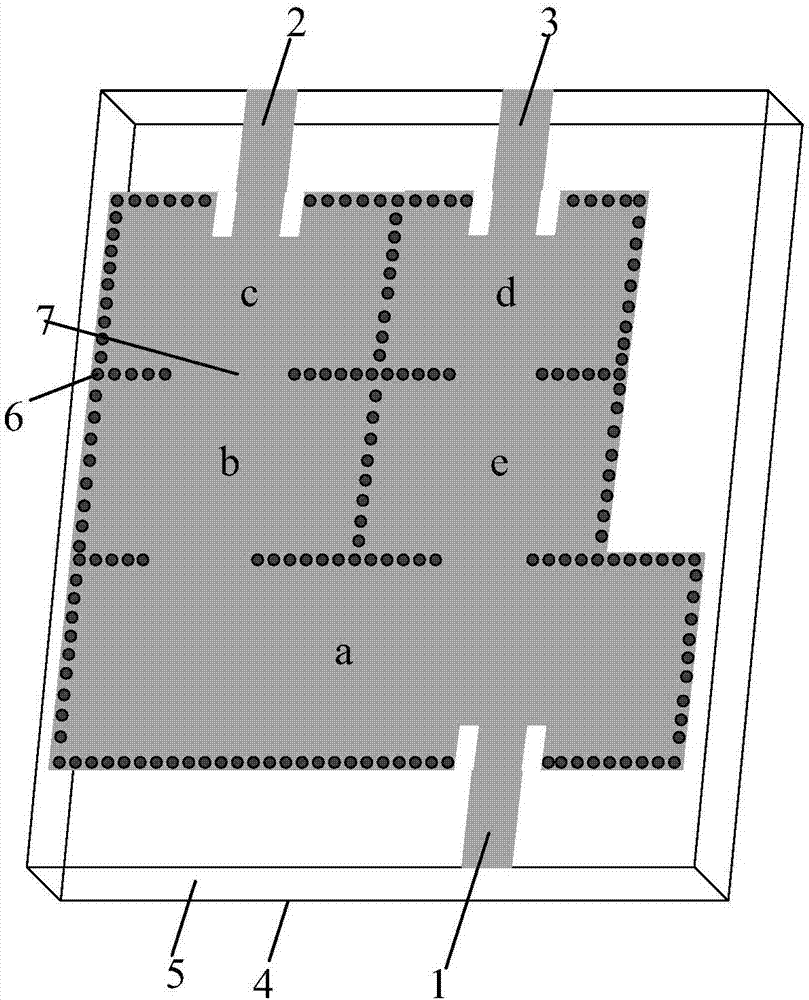

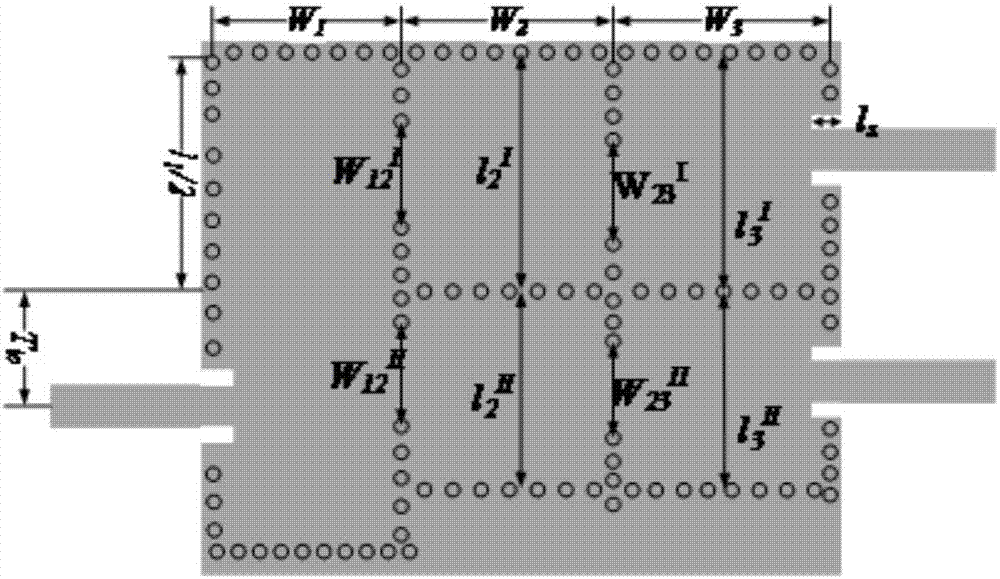

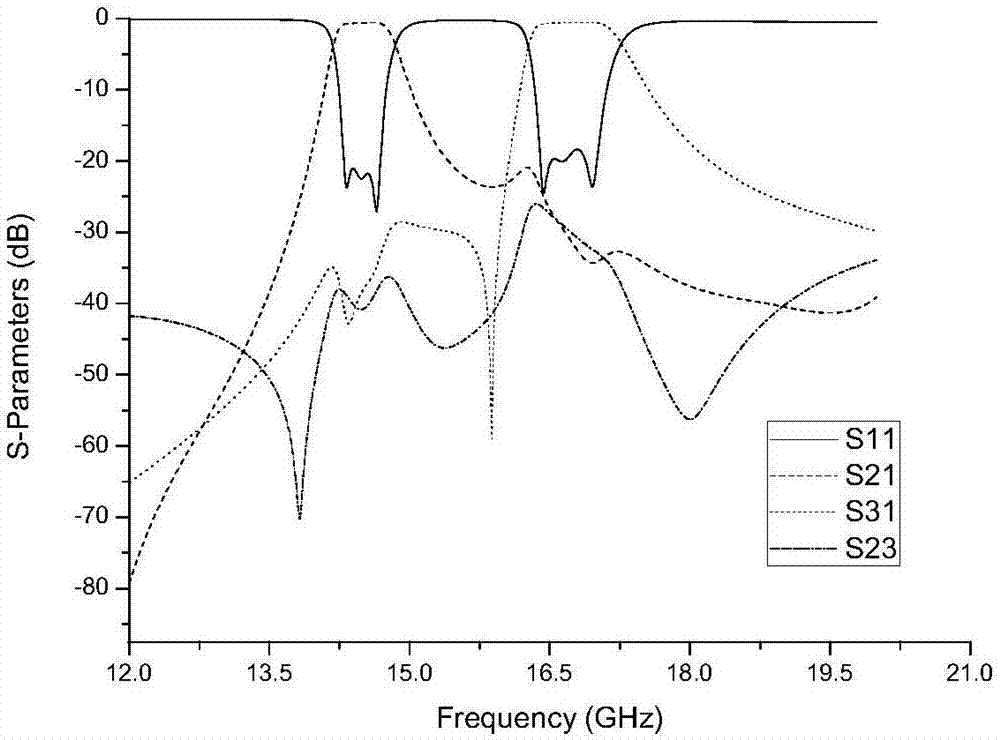

[0026] Such as figure 1 As shown, the present invention is based on a rectangular substrate integrated waveguide shared cavity duplexer, including a rectangular dielectric substrate 5, a metal ground layer 4 fully attached to the lower surface of the dielectric substrate 5, and metal attached to the upper surface of the dielectric substrate 5. Layer 3 also includes a plurality of metallized through holes 6 penetrating through the dielectric substrate 5 to connect the metal layer 3 and the ground layer 4;

[0027] The plurality of metallized through holes 6 enclose a rectangular common cavity a, a first low frequency rectangular cavity b and a first high frequency rectangular cavity e adjacent to a long side of the common cavity a, and the first low frequency rectangular cavity respectively b connected to the second low frequency rectangular cavity c and connected to the first high frequency rectangular cavity e and the second high frequency rectangular cavity d;

[0028] The first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com