Desiccated coconut laver egg roll and manufacturing method thereof

A technology of egg rolls and shredded coconut, which is applied in baking, dough processing, baked food, etc., can solve the problems of single variety and taste, and achieve the effect of uniform thickness, complete appearance and uniform color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

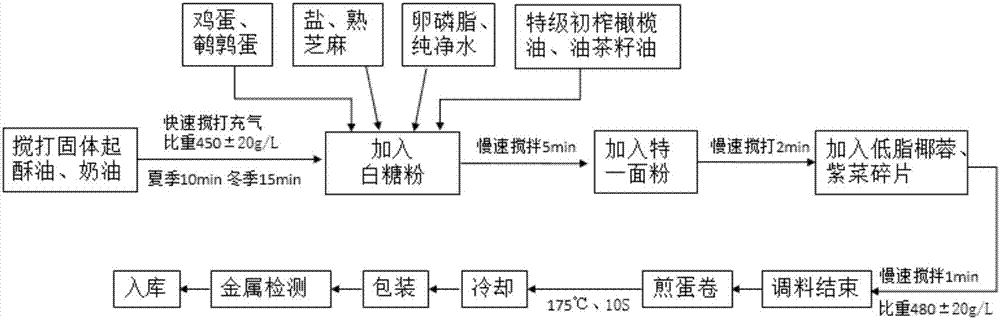

Method used

Image

Examples

Embodiment 1

[0027] The formula used for the egg rolls in this example includes by weight percentage: 27.5% special flour, 9% low-fat shredded coconut, 14% solid shortening, 5% butter, 15% eggs, 4% quail eggs, and 19% white sugar , Laver fragments 1.5%, camellia oil 1.1%, extra virgin olive oil 1.5%, lecithin 0.4%, cooked sesame 1%, edible salt 0.5%, drinking water 0.5%.

[0028] The production method of egg roll in the present embodiment is:

[0029] (1) Grinding powdered sugar: crush the white granulated sugar and pass through a 18-mesh sieve, and take the white granulated sugar under the sieve for later use;

[0030] (2) Sesame frying: fry the black sesame after removing impurities and washing in a wok with a stirring device;

[0031] (3) Beating: Put solid shortening and butter into a horizontal mixer, first stir at 20rpm for 2 minutes until the oil is stirred into a paste without obvious agglomeration, then stir and inflate at 70rpm until the slurry becomes a density of 450± 20g / L g...

Embodiment 2

[0035]The formula used for the egg rolls in this example includes, by weight percentage: 26% special flour, 8% low-fat shredded coconut, 16% solid shortening, 5.1% cream, 12% eggs, 7% quail eggs, and 20% white sugar , Laver fragments 1.2%, camellia oil 1.2%, extra virgin olive oil 1.2%, lecithin 0.4%, cooked sesame 0.9%, edible salt 0.5%, drinking water 0.5%.

[0036] The production method of egg rolls in the present embodiment is the same as in Example 1.

Embodiment 3

[0038] The formula used for the egg rolls in this example includes by weight percentage: 25% special flour, 7% low-fat shredded coconut, 18% solid shortening, 4% cream, 14% eggs, 6% quail eggs, and 20.3% white sugar , laver fragments 0.8%, camellia oil 1.5%, extra virgin olive oil 1%, lecithin 0.3%, cooked sesame 1.1%, edible salt 0.5%, drinking water 0.5%.

[0039] The production method of egg rolls in the present embodiment is the same as in Example 1.

[0040] Effect example

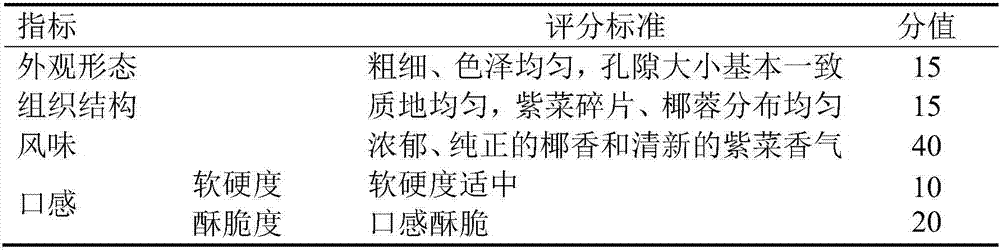

[0041] For the egg rolls of Examples 1 to 3, sensory evaluation was carried out by 15 experienced egg roll professionals, and the appearance, structure, local flavor, and mouthfeel (hardness, crispness) indicators of the egg rolls were evaluated. And the weights (based on a full score of 100 points) are as described in Table 1:

[0042] Table 1 Sensory scoring criteria

[0043]

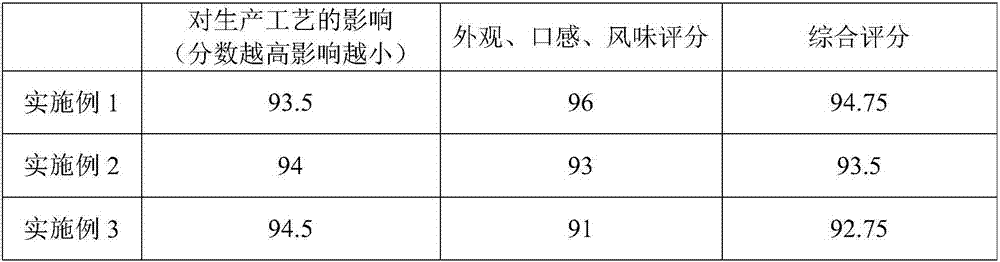

[0044] According to the sensory evaluation standard, the sensory evaluation results of Examples 1-3 are as shown in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com