Blocky magnetic carpet and preparing method thereof

A magnetic and carpet technology, which is applied in the field of block magnetic carpets and its preparation, can solve the problems of hidden warpage indicators of carpets, difficulty in ensuring the dimensional stability of carpets, and affecting the effect of carpet paving, etc. Effects of warping and delamination, quick and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

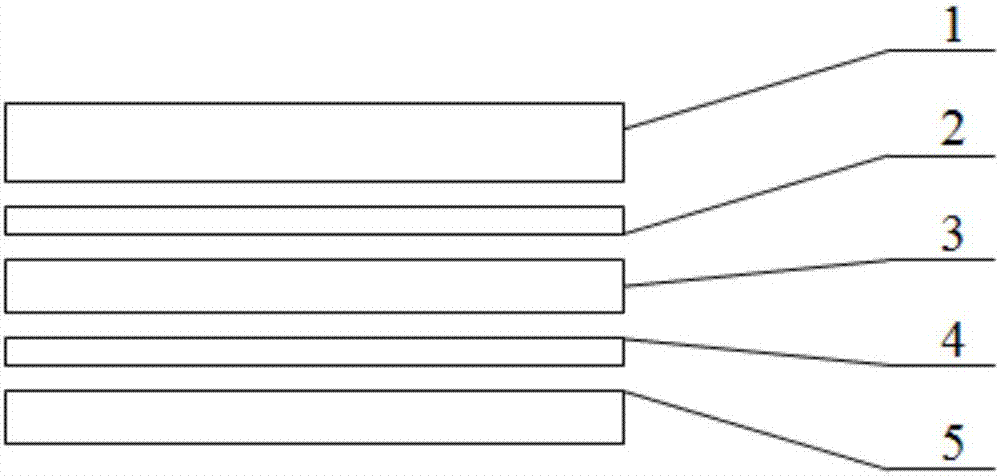

Method used

Image

Examples

Embodiment 1

[0034] The ethylene-vinyl acetate copolymer of 42 weight parts, the calcium carbonate (325 orders) of 45 weight parts, the auxiliary material of 2 weight parts, mix with the water of 12 weight parts, obtain the EVA glue for pre-coating, auxiliary material is penetration agent, Combination of dispersant, blowing agent and linking agent.

[0035] After foaming the obtained pre-coating with EVA glue, it is coated on the back side of the blank (wherein the blank is made by planting the tufted heads on the non-woven fabric), scraped off with a scraper, and placed in an oven for 150 ℃ for curing reaction and drying to obtain a pre-coated blank, the pre-coated layer is coated with a dry glue weight of 550 grams per square meter, and the width of the machine is 2.06 meters (corresponding to the width of the product 50 cm * 4 pieces) Require).

[0036] With the polyvinyl chloride paste resin of 10 weight parts, the plasticizer of 12 weight parts, the permanent magnetic powder of 21 we...

Embodiment 2

[0040] The ethylene-vinyl acetate copolymer of 43 parts by weight, the calcium carbonate (325 orders) of 42 parts by weight, the auxiliary material of 2 weight parts, mix with the water of 10 parts by weight, obtain the EVA glue for pre-coating, auxiliary material is penetration agent, Combination of dispersant, blowing agent and linking agent.

[0041] After the obtained pre-coating is foamed with EVA glue, it is coated on the back side of the blank (wherein the blank is made by planting the tufted pile on the non-woven fabric), scraped off with a scraper, and placed in an oven for 152 ℃ for curing reaction and drying to obtain a pre-coated blank, the pre-coated layer is coated with a dry glue weight of 500 grams per square meter, and the width of the machine is 2.05 meters (corresponding to the width of the product 50 cm * 4 pieces) Require).

[0042]With the polyvinyl chloride paste resin of 16 parts by weight, the plasticizer of 10 parts by weight, the permanent magnetic ...

Embodiment 3

[0046] The ethylene-vinyl acetate copolymer of 45 parts by weight, the calcium carbonate (325 orders) of 40 parts by weight, the auxiliary material of 2 parts by weight, mix with the water of 10 parts by weight, obtain the EVA glue for pre-coating, auxiliary material is penetration agent, Combination of dispersant, blowing agent and linking agent.

[0047] After the obtained pre-coating is foamed with EVA glue, it is coated on the back side of the blank (wherein the blank is made by planting the tufted pile on the non-woven fabric), scraped off with a scraper, and placed in an oven for 152 ℃ for curing reaction and drying to obtain a pre-coated blank, the pre-coated layer is coated with a dry glue weight of 570 grams per square meter, and the width of the machine is 2.045 meters (corresponding to the width of the product 50 cm * 4 pieces Require).

[0048] With the polyvinyl chloride paste resin of 10 weight parts, the plasticizer of 16 weight parts, the permanent magnetic po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetism | aaaaa | aaaaa |

| magnetism | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com