Novel medical bandage

A bandage and a new type of technology, applied in the field of medical supplies, can solve the problems of difficulty in supporting and protecting, poor air permeability, affecting wound healing time, etc., and achieve the effects of easy availability, low production cost and strong functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

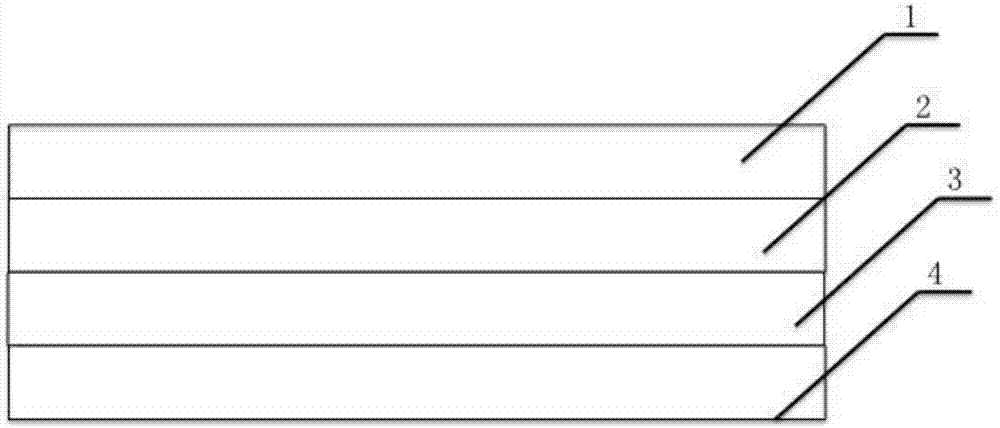

[0035] Such as figure 1 Shown, a kind of novel medical bandage comprises non-woven fabric layer 1, weft yarn layer 2, warp yarn layer 3 and polyurethane sponge layer 4, and each layer is closely connected.

[0036] The fibers in the weft yarn layer 2 are arranged in a cross shape.

[0037] The fibers in the warp layer 3 are crimped.

[0038] The non-woven fabric layer 1 comprises the following components: by weight components,

[0039] Polylactic acid: 60 parts

[0041] Flax fiber: 20 parts

[0042] Citric acid: 0.1 parts

[0043] Kaolin: 2 parts

[0044] Ethylene glycol: 2 parts

[0045] Diatomaceous earth: 2 parts.

[0046] Described weft yarn layer 2 comprises following components: by weight component,

[0047] Cotton fiber: 35 parts

[0048] Soy protein fiber: 45 servings

[0049] Flax fiber: 20 parts

[0050] Milk protein fiber: 35 servings.

[0051] Described warp yarn layer 3 comprises following components: by weight componen...

Embodiment 2

[0061] Such as figure 1 Shown, a kind of novel medical bandage comprises non-woven fabric layer 1, weft yarn layer 2, warp yarn layer 3 and polyurethane sponge layer 4, and each layer is closely connected.

[0062] The fibers in the weft yarn layer 2 are arranged in a cross shape.

[0063] The fibers in the warp layer 3 are crimped.

[0064] The non-woven fabric layer 1 comprises the following components: by weight components,

[0065] Polylactic acid: 68 parts

[0066] Chitin fiber: 24 parts

[0067] Flax fiber: 22 parts

[0068] Citric acid: 0.2 parts

[0069] Kaolin: 2 parts

[0070] Ethylene glycol: 3 parts

[0071] Diatomaceous earth: 2 parts.

[0072] Described weft yarn layer 2 comprises following components: by weight component,

[0073] Cotton fiber: 38 parts

[0074] Soy protein fiber: 47 servings

[0075] Flax fiber: 24 servings

[0076] Milk protein fiber: 35 servings.

[0077] Described warp yarn layer 3 comprises following components: by weight compo...

Embodiment 3

[0087] Such as figure 1 Shown, a kind of novel medical bandage comprises non-woven fabric layer 1, weft yarn layer 2, warp yarn layer 3 and polyurethane sponge layer 4, and each layer is tightly connected.

[0088] The fibers in the weft yarn layer 2 are arranged in a cross shape.

[0089] The fibers in the warp layer 3 are crimped.

[0090] The non-woven fabric layer 1 comprises the following components: by weight components,

[0091] Polylactic acid: 68 parts

[0092] Chitin fiber: 28 parts

[0093] Flax fiber: 28 servings

[0094] Citric acid: 0.2 parts

[0095] Kaolin: 3 parts

[0096] Ethylene glycol: 4 parts

[0097] Diatomaceous earth: 3 parts.

[0098] Described weft yarn layer 2 comprises following components: by weight component,

[0099] Cotton fiber: 40 parts

[0100] Soy protein fiber: 50 servings

[0101] Flax fiber: 28 servings

[0102] Milk protein fiber: 40 servings.

[0103] Described warp yarn layer 3 comprises following components: by weight comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com