Vertical drilling machine cooling device for lug-hole boring of transmission shaft flange fork

A vertical drilling machine and cooling device technology, which is applied to metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of difficult heat dissipation, complex processing technology, difficult workpiece processing, etc., and achieve cooling Good effect, flexible bending, accelerated cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further specifically described below through embodiments and in conjunction with the accompanying drawings.

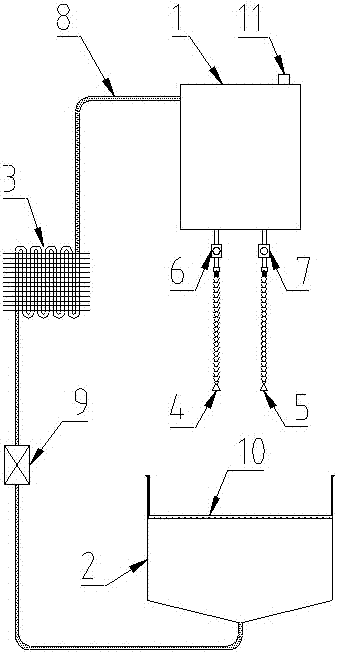

[0019] Such as figure 1 As shown, the present invention provides a cooling device for a vertical drilling machine for drilling the lug holes of the fork of the drive shaft, including a cooling liquid storage tank 1, a cooling liquid recovery bucket 2, a cooler 3 and a control system. The coolant storage tank 1 is used to store the low-temperature coolant after natural cooling. Specifically, the coolant storage tank 1 is a relatively closed box structure to ensure the relative purity of the coolant. During specific implementation, the coolant can be stored The box 1 is suspended on the vertical drilling machine, or independently supported by a bracket on the ground near the processing site. The coolant recovery bucket 2 is used to collect the high-temperature coolant flowing down from the processing part, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com