Manufacturing method for diamond and resin combined grinding block and diamond and resin combined grinding block

A manufacturing method and a grinding block technology, which are applied in the manufacture of tools, abrasives, grinding devices, etc., can solve the problems of unstable service life, wear scars, and poor sharpness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

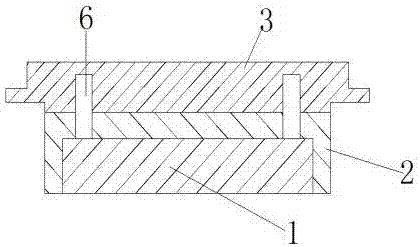

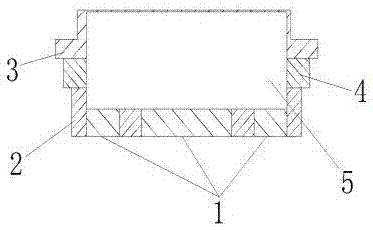

[0047] Embodiment 1: In this embodiment, the unsaturated polyester resin is selected as 196 o-phthalic general-purpose unsaturated polyester resin, and the manufacturing method of the diamond resin combined with the abrasive block includes the following manufacturing steps:

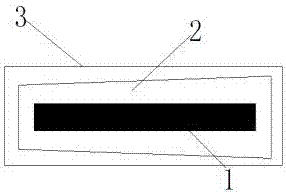

[0048] Making a diamond alloy grinding block 1;

[0049] Make resin bond 2;

[0050] Casting resin bond 2 to fix diamond alloy grinding block 1;

[0051] Among them, the steps of making the diamond alloy grinding block 1 include: batching, grinding, cold pressing, installing graphite molds, and hot pressing;

[0052] Diamond alloy grinding block 1 ingredients: get the following raw materials by weight percentage, iron powder 30%, copper powder 22%, nickel powder 1%, carbonyl iron powder 3%, phosphorus iron powder 3%, zinc powder 1%, aluminum powder 3%, 1% lead powder, 1% chromium powder, 1% diamond;

[0053] Diamond alloy grinding block 1 Grinding: The above raw materials are fully stirred and mixed an...

Embodiment 2

[0066] Embodiment 2: In this embodiment, the unsaturated polyester resin is selected as 191 orthophthalene general-purpose unsaturated polyester resin, and the manufacturing method of the diamond resin combined with the abrasive block includes the following manufacturing steps:

[0067] Make resin bond 2;

[0068] Making a diamond alloy grinding block 1;

[0069] Casting resin bond 2 to fix diamond alloy grinding block 1;

[0070] Wherein, the steps of making the resin bond 2 include: batching, mixing and proportioning curing agent;

[0071] Resin binder 2 ingredients: get the following raw materials in weight percentages, alumina powder 20%, quartz sand 20%, magnesium oxide 4%, white corundum 15%, talcum powder 8%, grinding block powder 60%, diamond 6%;

[0072] Resin binder 2 mixing: fully stir and mix the above raw materials;

[0073] Resin binder 2 proportioning curing agent: mix the raw materials with the following curing agent by weight percentage, 2% of 191 ophthalmi...

Embodiment 3

[0085] Embodiment three: In the present embodiment, the unsaturated polyester resin is selected as 196 o-phthalic general-purpose unsaturated polyester resin, and the manufacturing method of the diamond resin combined with the abrasive block includes the following manufacturing steps:

[0086] Making a diamond alloy grinding block 1;

[0087] Make resin bond 2;

[0088] Casting resin bond 2 to fix diamond alloy grinding block 1;

[0089] Among them, the steps of making the diamond alloy grinding block 1 include: batching, grinding, cold pressing, installing graphite molds, and hot pressing;

[0090] Diamond alloy grinding block 1 ingredients: get the following raw materials by weight percentage, iron powder 38%, copper powder 30%, nickel powder 3%, carbonyl iron powder 6%, phosphorus iron powder 6%, zinc powder 4%, aluminum powder 6%, 2% lead powder, 2% chromium powder, 3% diamond;

[0091] Diamond alloy grinding block 1 Grinding: The above raw materials are fully stirred a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com