Circular weaving machine warp carding board threading apparatus

A technology of circular looms and threaders, which is applied to circular looms, looms, textiles, etc., can solve the problems of working efficiency of using threading pieces alone, and the inability to hook threads with ordinary threading pieces, so as to save procedures and repeat procedures, The effect of increasing economic benefits and increasing work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

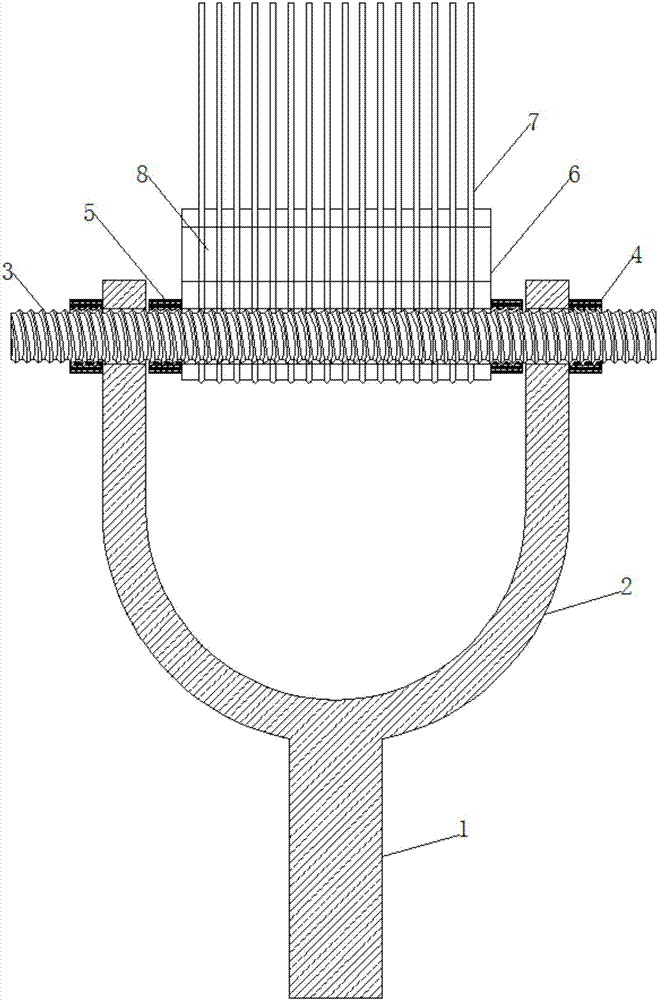

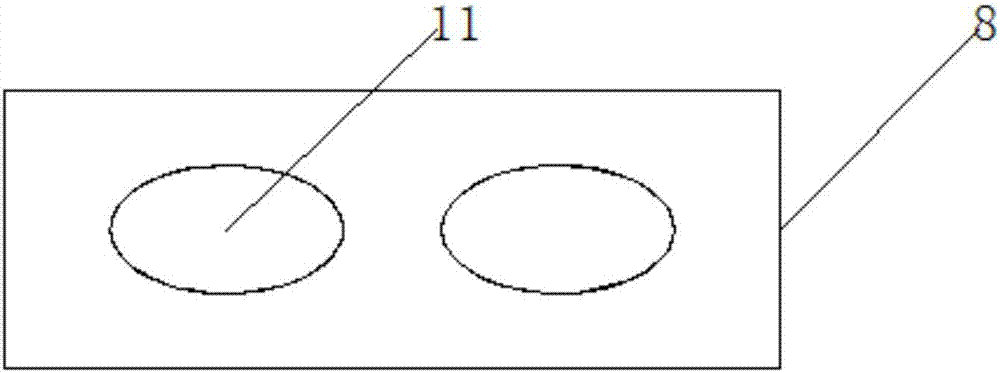

[0026] Please refer to Figure 5 , the two sets of connecting holes of the U-shaped bracket 2 are connected with the threaded rods 3 through the outer fixing nuts 4, the gasket 8 is sleeved on the two threaded rods 3 through the two second elliptical fixing holes 11, and the gasket 8 and the A threading piece 7 is clamped between the spacers 8, and the angle between the threading piece 7 and the threaded rod 3 is 15-30 degrees. The fixing method of this threading piece 7 is to squeeze and increase friction.

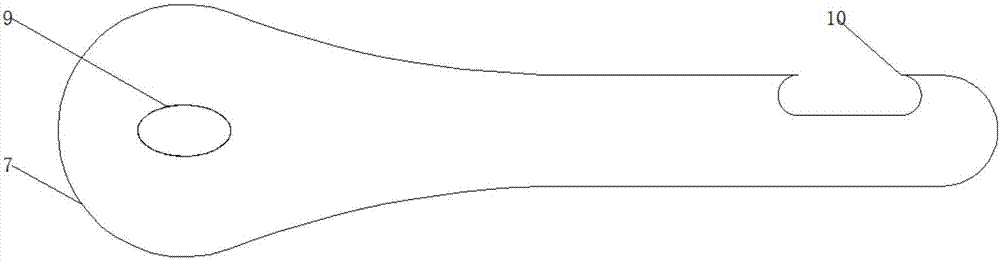

[0027] In summary, the present invention provides a semi-elliptical hook groove 10 on the threading piece 7, so that the threading piece 7 can not only top the thread but also be free, so that the threading piece 7 integrates the functions of hooking the thread and top thread into one One body makes the threading piece 7 more convenient when working, does not need to use foreign objects to hook the line, saves accessories, thereby saving expenses and increasing economic b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com