Domestic sewing-machine mechanical-clutch electric mechanical-clutch motor

A mechanical clutch and sewing machine technology, applied in sewing equipment, sewing machine components, sewing machine control devices, etc., can solve the problems of motor temperature rise and motor service life reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

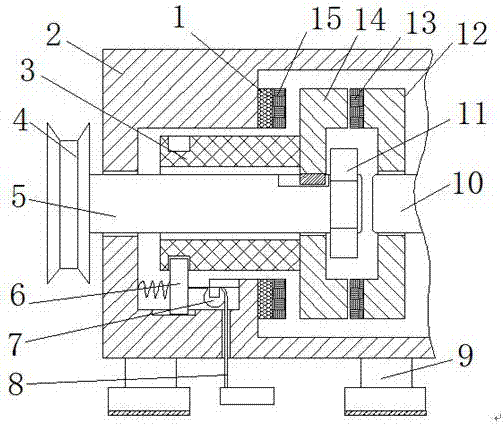

[0013] A household sewing machine mechanical clutch electromechanical clutch motor, comprising a motor casing 2, the bottom plate of the motor casing 2 is fixedly connected with a support seat 9, and the bottom side of the support seat 9 is fixedly connected with a shock absorbing pad, which effectively reduces the vibration of the motor. 2 is provided with an installation chamber, and the motor casing 2 is provided with a first installation groove communicating with the installation chamber. An installation hole is provided on the inner wall of one side of the first installation groove, and a rotating shaft 5 is arranged in the first installation groove, and one end of the rotating shaft 5 passes through The installation hole is fixedly sleeved with a pulley 4, the end of the rotating shaft 5 away from the pulley 4 extends into the installation cavity, the extension end of the rotating shaft 5 is threaded to the limit nut 11, and the end of the rotating shaft 5 close to the lim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com