Easy-stripped pressure-sensitive adhesive for stamping protecting film and preparation method for easy-stripped pressure-sensitive adhesive

An easy-peeling, pressure-sensitive adhesive technology, applied in the field of pressure-sensitive adhesives, can solve problems such as scratches on the surface of stamping products, insufficient cohesion of pressure-sensitive adhesives, and reduced service life of molds, achieving high shear strength and impact resistance. Practicality and ease of handling, not easy to slip or break the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

[0037] Embodiments 1-4: An easy-peelable pressure-sensitive adhesive for stamping protective film, consisting of the following components in parts by weight:

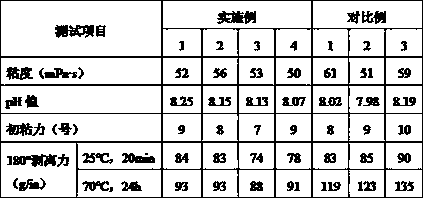

[0038] Table 1

[0039]

[0040] Wherein, the initiator in embodiment 1 is ammonium persulfate, and buffering agent is sodium bicarbonate; The initiator in embodiment 2 is ammonium persulfate, and buffering agent is sodium bicarbonate; The initiator in embodiment 3 is persulfuric acid Potassium, buffering agent is sodium carbonate; Initiator among the embodiment 4 is potassium persulfate, buffering agent is ammonium bicarbonate.

[0041] The preparation method of the easy-peeling pressure-sensitive adhesive for stamping protective film comprises the following steps:

[0042] S1. 25% of the total weight of butyl acrylate, 25% of the total weight of 2-ethylhexyl acrylate, 25% of the total weight of methyl methacrylate, 25% of the total weight of acrylic acid, and 25% of the total weight of hydroxyethyl acrylate 25% o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com