Method for determining best hole distributing mode for permeability increasing of carbon dioxide phase change cracking coal seam

A carbon dioxide and fracturing technology that is used in earth-moving drilling, wellbore/well components, production fluids, etc., and can solve problems such as single-hole measurement radius interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the described embodiments.

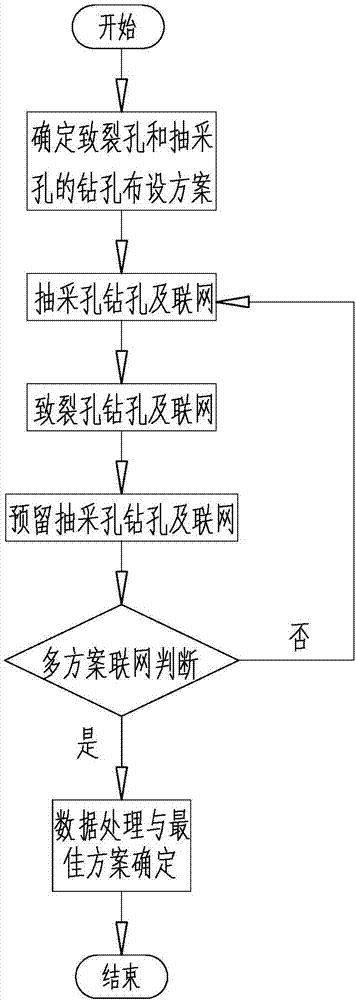

[0025] see figure 1 , figure 2 , a method for determining the optimal pore layout method for increasing permeability of carbon dioxide phase change fracturing coal seams, comprising the following steps:

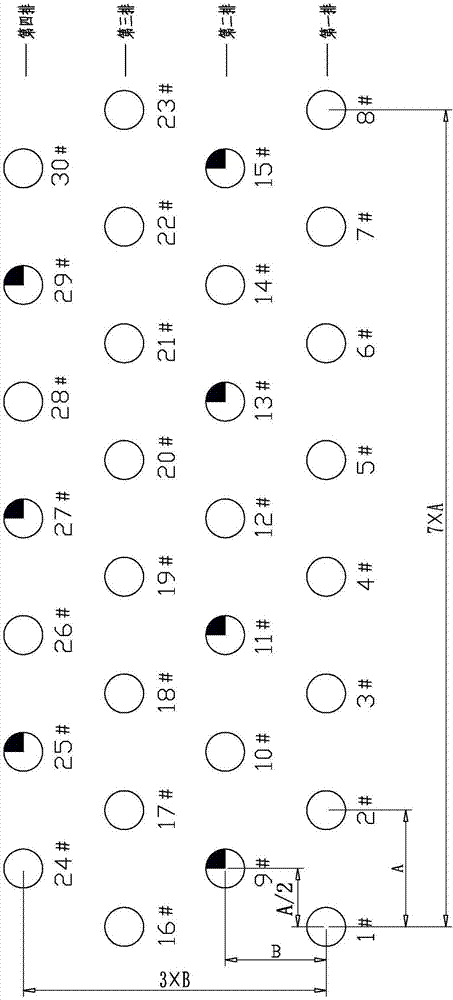

[0026] The first step is to determine multiple layout schemes for fracturing holes and drainage holes: four drilling schemes are arranged according to different hole spacings of 3m, 5m, 7m and 9m, and the four schemes are arranged in order of spacing from small to large They are named Scheme 1, Scheme 2, Scheme 3 and Scheme 4; the drill holes in the four schemes are arranged in 4 rows at equal intervals, and the hole spacing A in the same row is 3m, 5m, 7m and 9m respectively, as figure 2As shown, they are named as the first row, the second row, the third row and the fourth row fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com