Preparation method of doped polysiloxanes sol antireflection film based on interface modification

A technology of polysiloxane sol and anti-reflection film, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problem that the surface hardness of the anti-reflection film is not high enough, the scratch resistance is poor, and the performance and life of the product are affected and other problems, to achieve the effect of orderliness and low packing density, anti-reflection effect, and increase surface hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

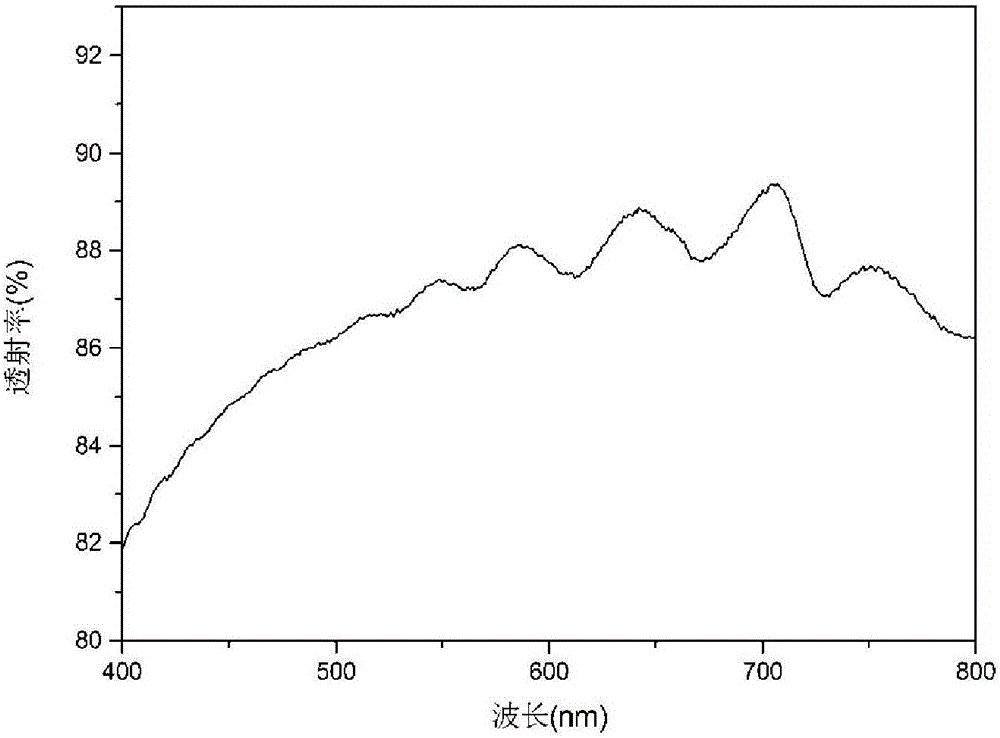

Embodiment 1

[0036] (1) Configure SiO 2 Sol: Alkaline SiO was prepared from tetraethyl orthosilicate, absolute ethanol, deionized water and ammonia water as raw materials 2 Sol, wherein the molar ratio of ethyl orthosilicate: absolute ethanol: deionized water: ammonia water is 1:45:3:0.1. Preparation of basic SiO 2 The method of sol is: after magnetically stirring the ethyl orthosilicate absolute ethanol solution for 3-10 minutes, add the solution of absolute ethanol, deionized water and ammonia water dropwise to the ethyl orthosilicate absolute ethanol solution, and continue After magnetic stirring for 2 h, seal and age at room temperature for 5 d.

[0037] (2) SiO 2 Sol modification treatment: Alkaline SiO 2 The sol is modified by polysiloxane modification technology to obtain a coating solution. Doped with polysiloxane and SiO 2 The volume ratio of the sol was 8%.

[0038](3) Clean the glass substrate, immerse the cleaned glass substrate in the sol, pull it after soaking for 30s,...

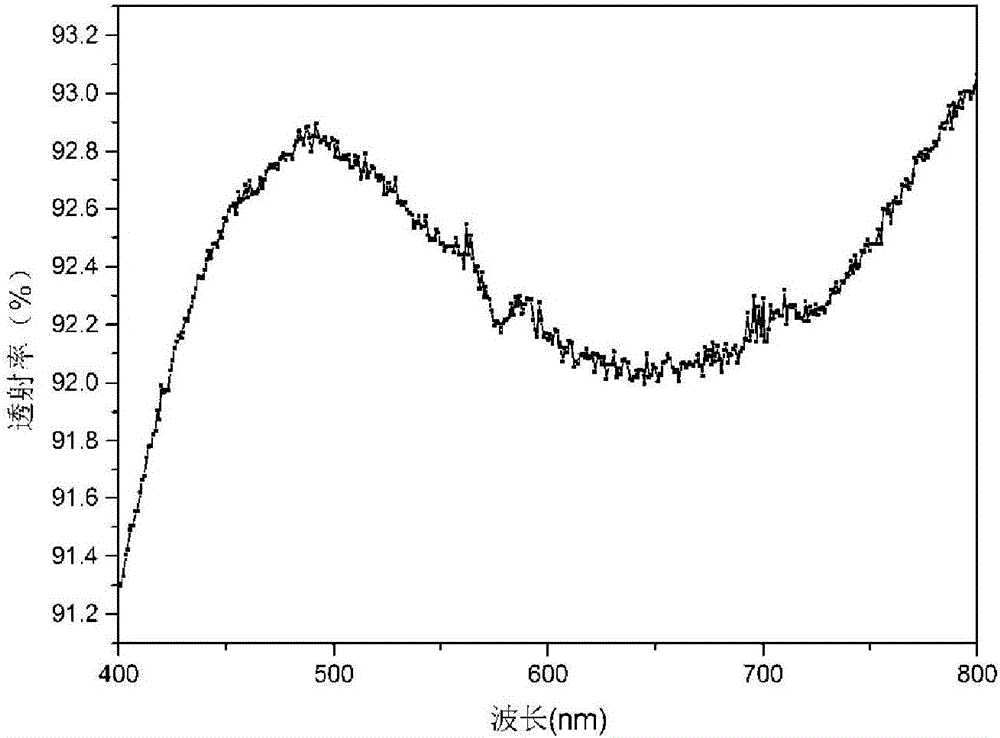

Embodiment 2

[0044] (1) Configure SiO 2 Sol: Alkaline SiO was prepared from tetraethyl orthosilicate, absolute ethanol, deionized water and ammonia water as raw materials. 2 Sol, wherein the molar ratio of ethyl orthosilicate: absolute ethanol: deionized water: ammonia water is 1:60:8:0.1. Preparation of basic SiO 2 The method of sol is: after magnetically stirring the ethyl orthosilicate absolute ethanol solution for 3-10 minutes, add the solution of absolute ethanol, deionized water and ammonia water dropwise to the ethyl orthosilicate absolute ethanol solution, and continue After magnetically stirring until uniform, seal and age at room temperature for 5 days.

[0045] (2) SiO 2 Sol modification treatment: Alkaline SiO 2 The sol is modified by polysiloxane modification technology to obtain a coating solution. Doped with polysiloxane and SiO 2 The volume ratio of the sol was 12%.

[0046] (3) Clean the glass substrate, immerse the cleaned glass substrate in the sol, pull it after ...

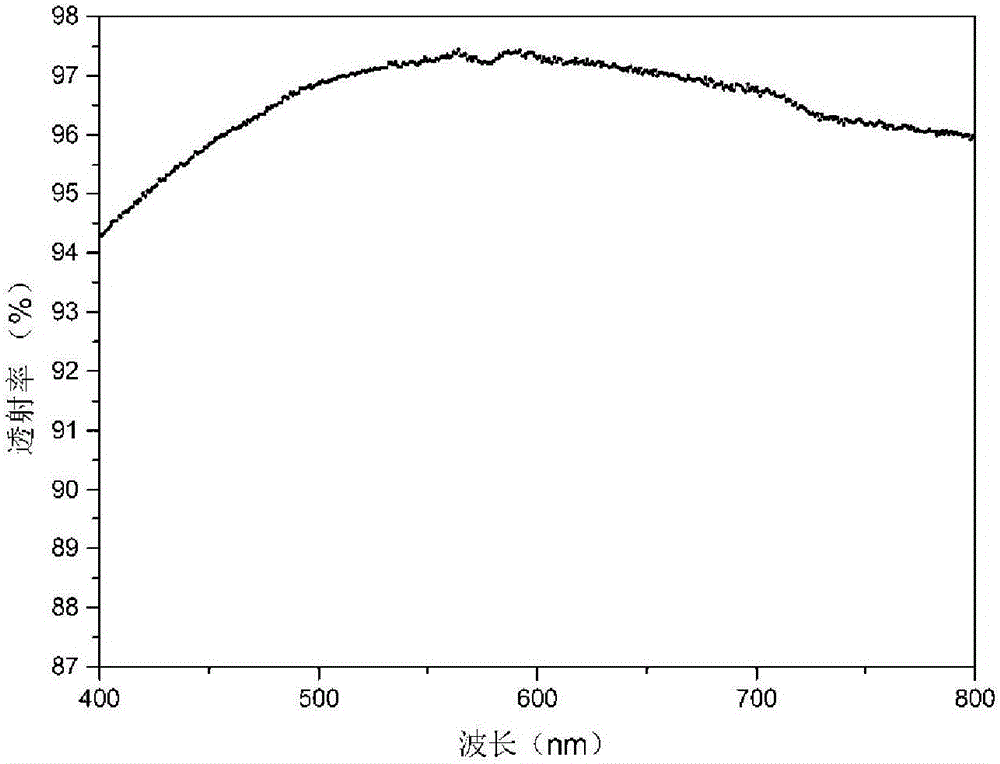

Embodiment 3

[0052] (1) Configure SiO 2 Sol: Alkaline SiO was prepared from tetraethyl orthosilicate, absolute ethanol, deionized water and ammonia water as raw materials. 2 Sol, wherein the molar ratio of ethyl orthosilicate: absolute ethanol: deionized water: ammonia water is 1:80:1:0.1. Preparation of basic SiO 2 The method of sol is: after magnetically stirring the ethyl orthosilicate absolute ethanol solution for 3-10 minutes, add the solution of absolute ethanol, deionized water and ammonia water dropwise to the ethyl orthosilicate absolute ethanol solution, and continue After magnetically stirring until uniform, seal and age at room temperature for 5 days.

[0053] (2) SiO 2 Sol modification treatment: Alkaline SiO 2 The sol is modified by polysiloxane modification technology to obtain a coating solution. Doped with polysiloxane and SiO 2 The volume ratio of the sol was 2%.

[0054] (3) Clean the glass substrate, immerse the cleaned glass substrate in the sol, pull it after s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com