Surface anti-reflection light-emitting diode

A technology of light-emitting diodes and anti-reflection layers, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of reducing process controllability and yield, increasing process complexity, increasing product costs, etc., to improve current expansion effect, anti-reflection effect is remarkable, and the effect of good precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

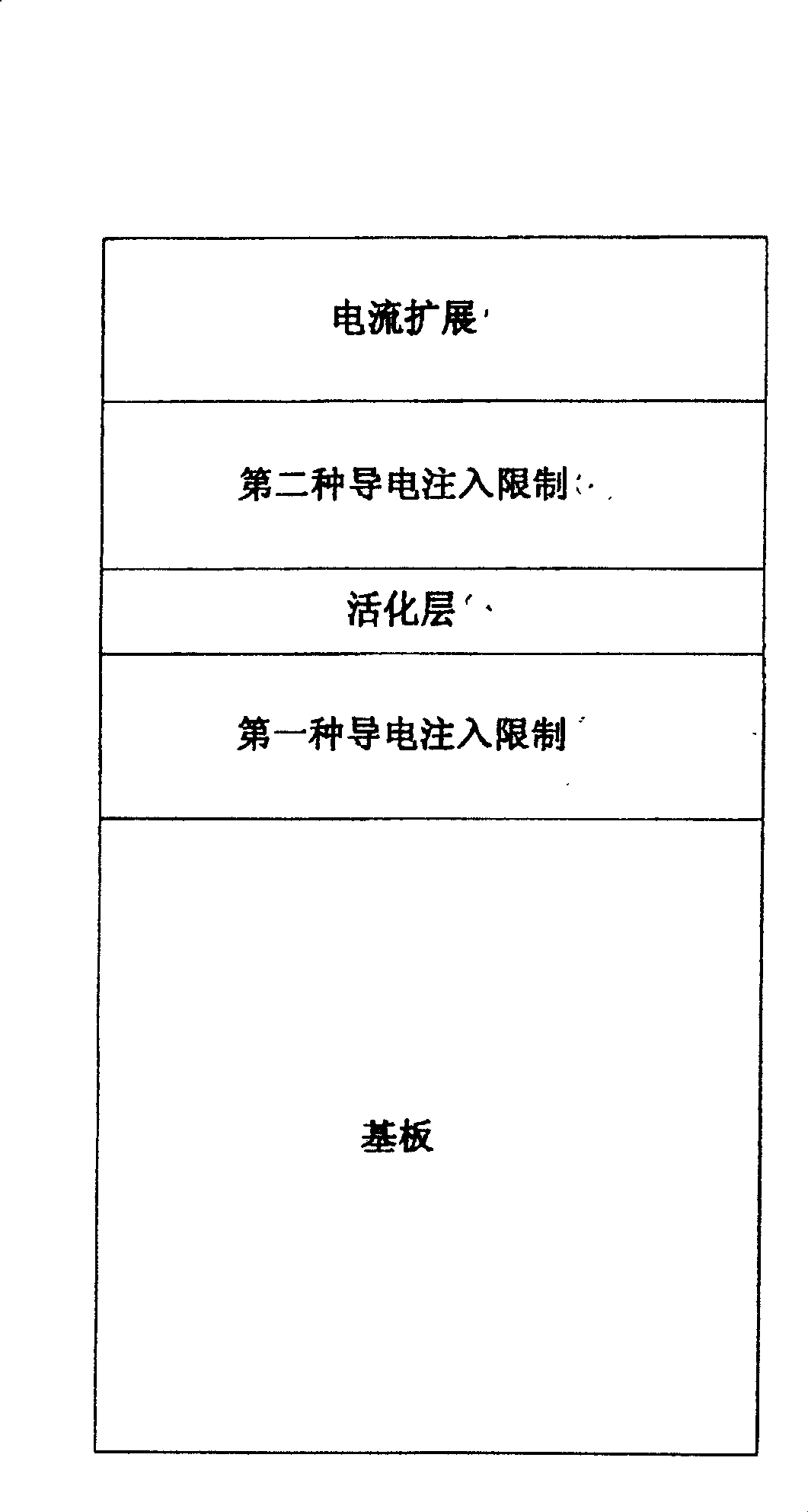

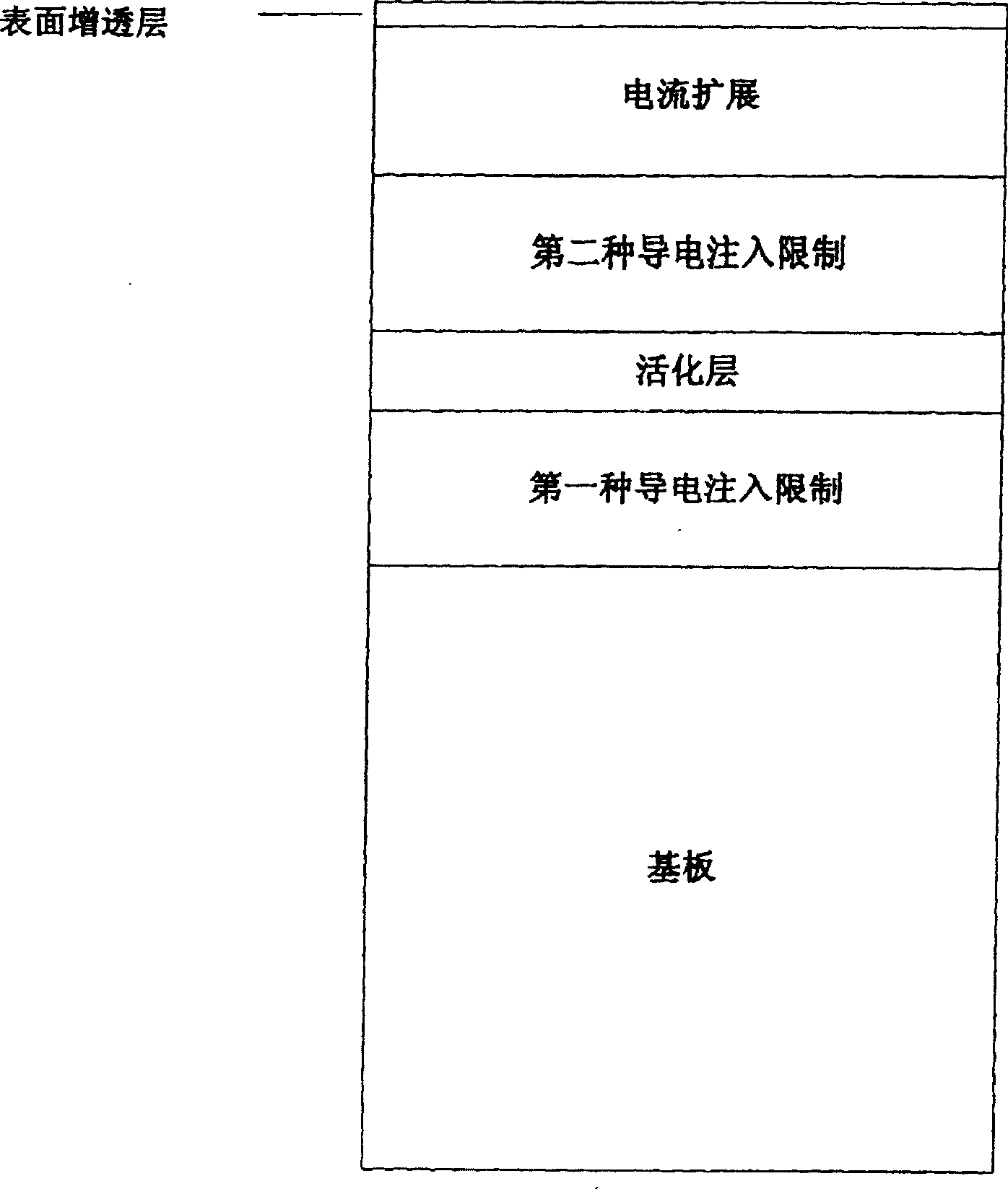

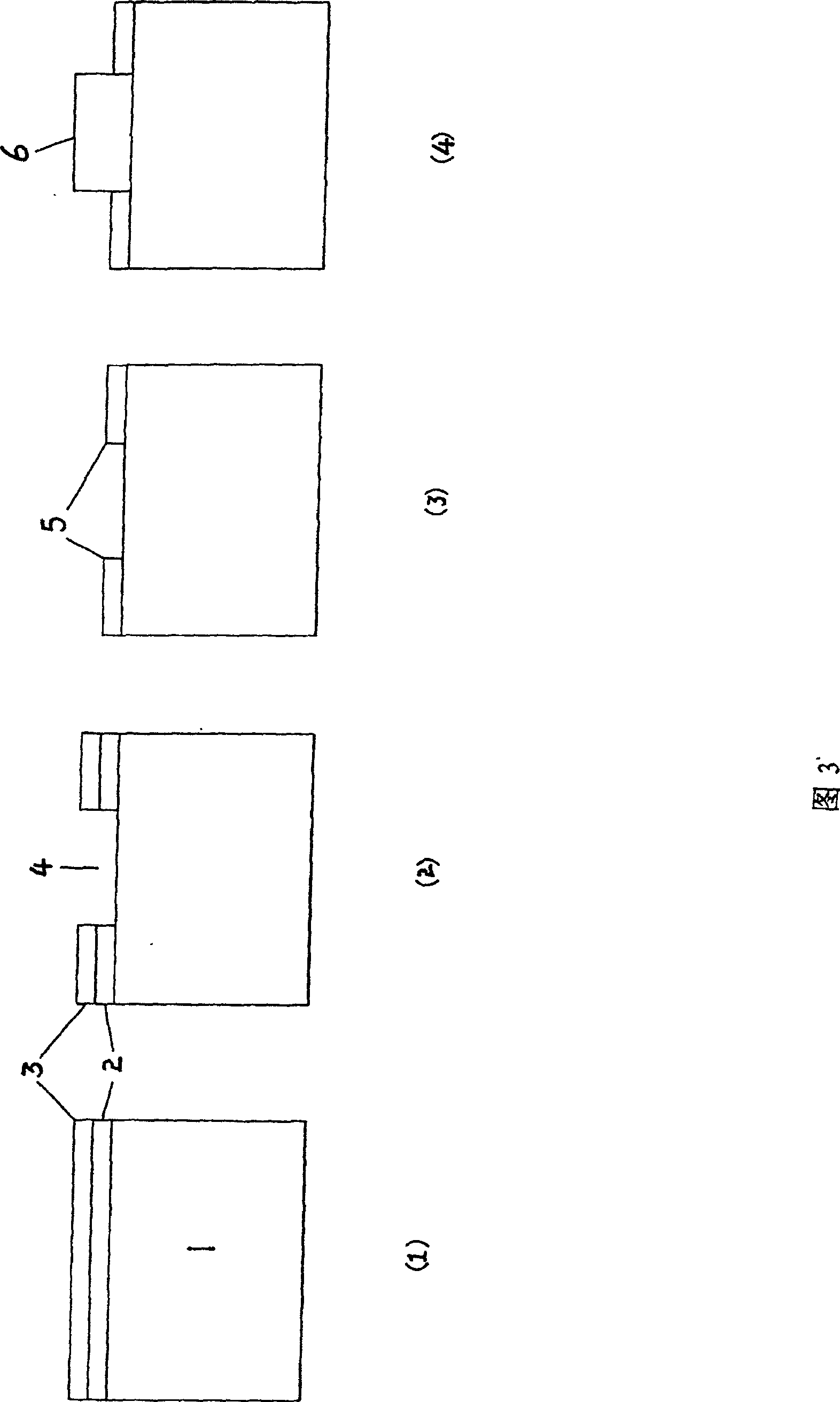

[0015] figure 1 Light-emitting diode conventional structure, figure 2 It is an epitaxial growth structure of the diode of the present invention. The typical difference between the structure of the present invention and the conventional structure is that there is a surface anti-reflection film grown in the epitaxial process on the window layer, in this example, it is AlxGa1-xAs (x=80%), and its thickness will satisfy the anti-reflection coating after oxidation. Transparent effect, such as for 625 red light emitting diodes, the thickness is 1200 angstroms. remove figure 2 structure, the surface of AlGaAs can also be covered with a protective layer such as GaAs or GaInP that is not easily oxidized (as shown in Figure 3(1), 3(2)).

[0016] Figure 3 is the process route for preparing the light emitting diode of the present invention: (a) as shown in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com