High-pulsation-resistance exhaust system design method of piston engine and exhaust system

A piston engine and exhaust system technology, applied to engine components, machines/engines, exhaust treatment, etc., can solve the problems of weakening the mechanical vibration of the supercharger and large pressure pulsation at the inlet of the turbine, so as to achieve stable operation and damping Good shock absorption effect and reduce wear and tear of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

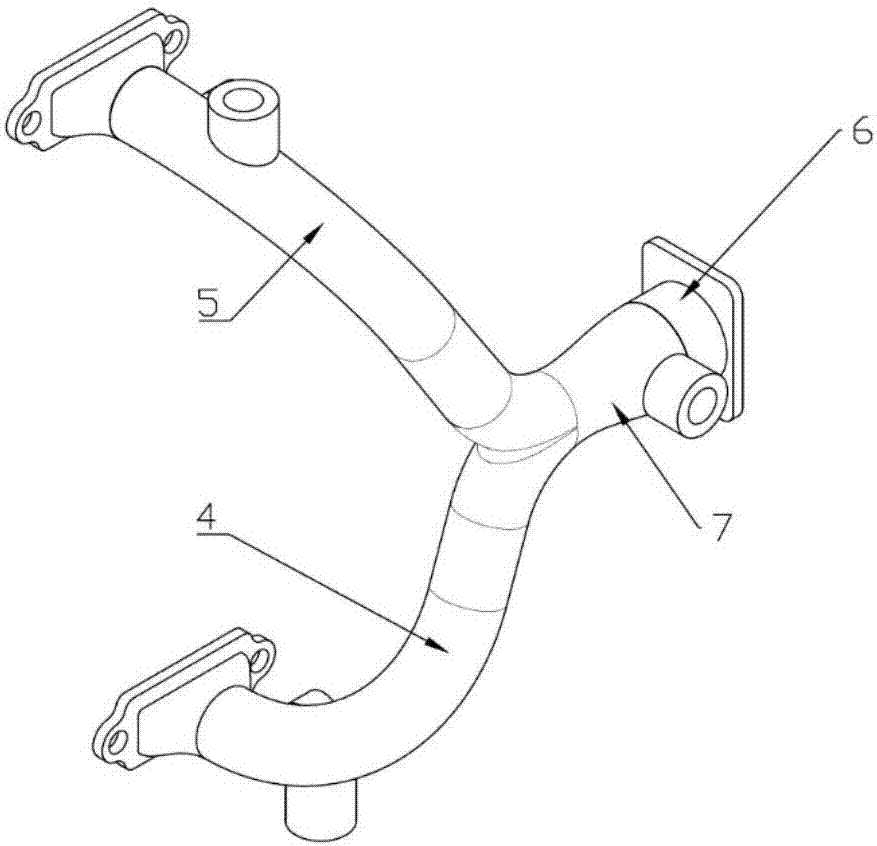

[0035] Such as figure 1 As shown, the pipeline system in the anti-high pulsation exhaust system of the present invention is directly connected with the exhaust port of the engine cylinder.

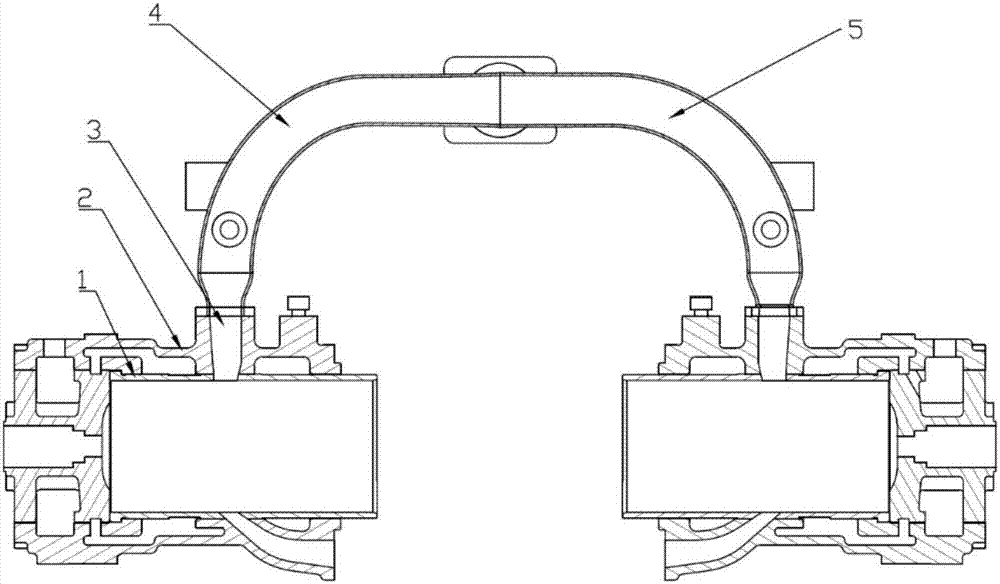

[0036] Such as figure 2 As shown, the anti-high pulsation exhaust system involved in the present invention mainly includes three parts: two exhaust manifolds, an exhaust manifold containing an exhaust regulator, and a large damping anti-high pulsation Floating thrust bearing.

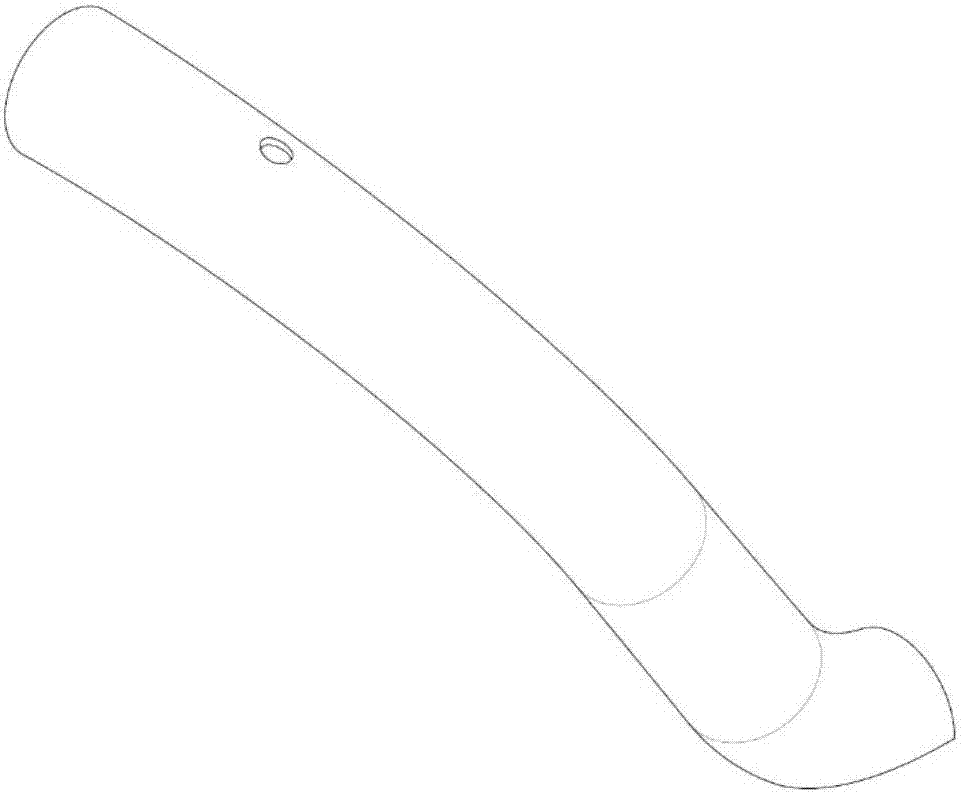

[0037] Such as image 3 As shown, the design of the exhaust manifold not only includes the design of the length and diameter, but also includes the planning of the specific shape line. The shape line design of the manifold has a great influence on the loss in the exhaust process of the engine.

[0038] Such as Figure 4 As shown, the exhaust regulator designed on the exhaust ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com