System for detecting surface defects of metal plate based on deep convolution neural network

A technology of metal strip and deep convolution, which is applied in the direction of biological neural network model, neural architecture, optical test defects/defects, etc., can solve the problems that cannot meet the accuracy and real-time requirements of industrial on-line detection, and improve detection speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

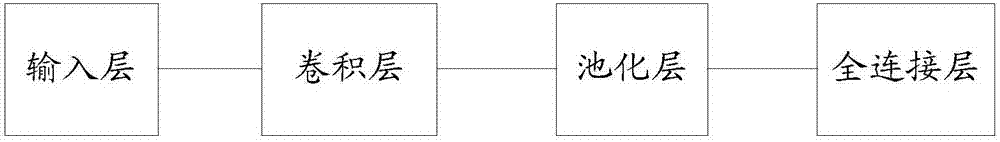

[0027] Aiming at the existing problem that the real-time requirements of on-line detection in the industry cannot be met, the present invention provides a metal strip surface defect detection system based on a deep convolutional neural network.

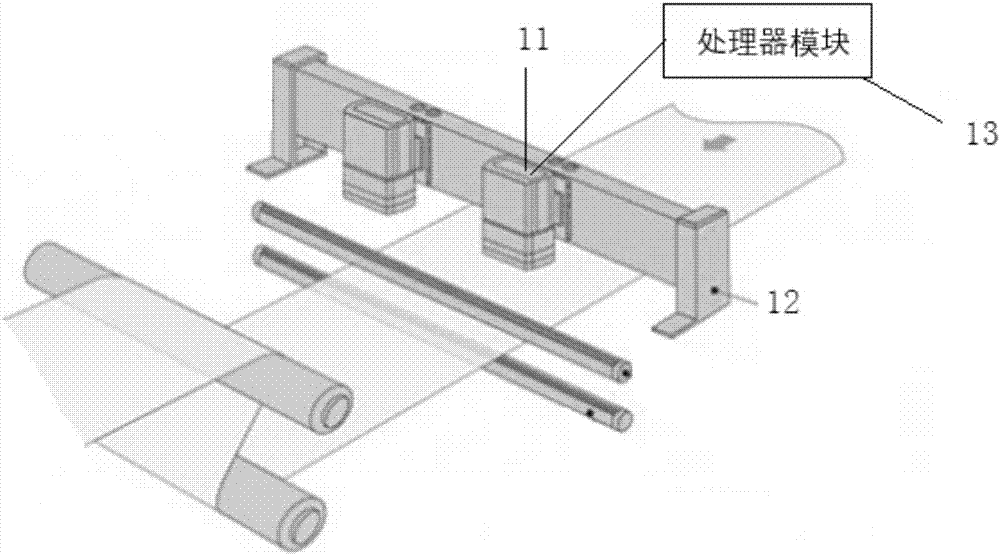

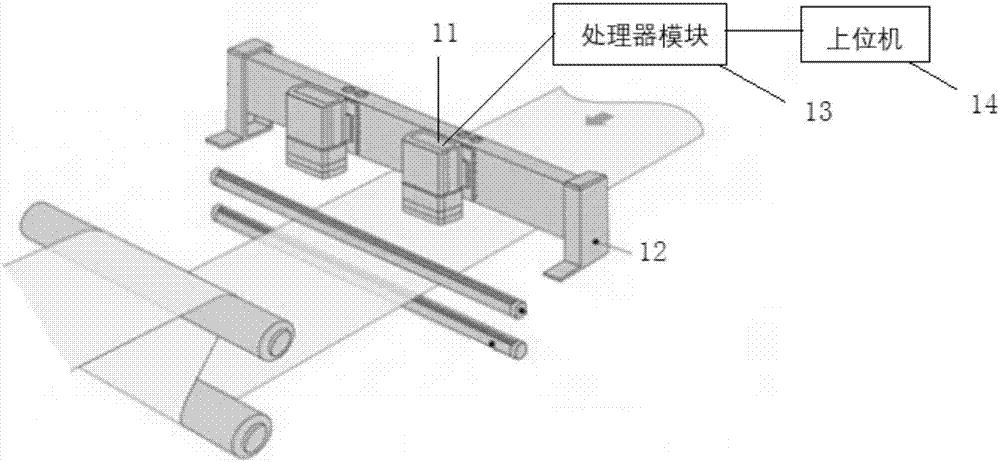

[0028] Such as figure 1 As shown, the metal strip surface defect detection system based on the deep convolutional neural network provided by the embodiment of the present invention includes: a camera 11, a mounting frame 12 for installing the camera 11, and a processor module 13; wherein,

[0029] The mounting frame 12 straddles the industrial site conveyor belt;

[0030] The camera 11 is installed on the mounting frame 12 for real-time collection of surface images of metal strips on the conveyor belt;

[0031...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com