Array substrate, preparation method thereof and liquid crystal panel

An array substrate and substrate substrate technology, which is applied in semiconductor/solid-state device manufacturing, optics, instruments, etc., can solve the problems of low utilization efficiency of backlight sources, and achieve the effects of easy operation, simple preparation process, and reduced production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In the present invention, unless stated to the contrary, the used orientation words such as "up, down, left, and right" usually refer to the orientations shown in the drawings and the orientations in practical applications.

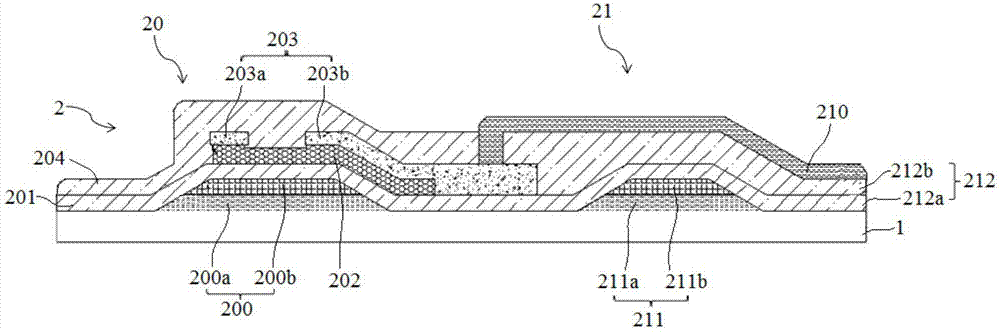

[0030] The present invention provides an array substrate, which includes a base substrate 1, a plurality of pixel units 2 formed on the base substrate 1 and distributed in an array, each pixel unit 2 includes a thin film transistor switch 20, wherein , the thin film transistor switch 20 includes a grid 200 formed on the base substrate 1, the grid 200 includes a first reflective layer 200a formed on the base substrate 1, and the grid 200 can reflect back the light passing through the grid 200 itself . By setting the grid 200 containing the first reflective layer 200a on the base substrate 1, so that when the light emitted by the backlight passes through the array substrate, the grid 200 can reflect back the light passing through itself, so that when...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com