An infrared display device

A display device and infrared technology, which is applied to identification devices, instruments, calculations, etc., can solve the problems of infrared display products losing operation effects, devices failing to be developed, and working task conditions without light, etc., to achieve clear and effective infrared display effects, The effect of light weight and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

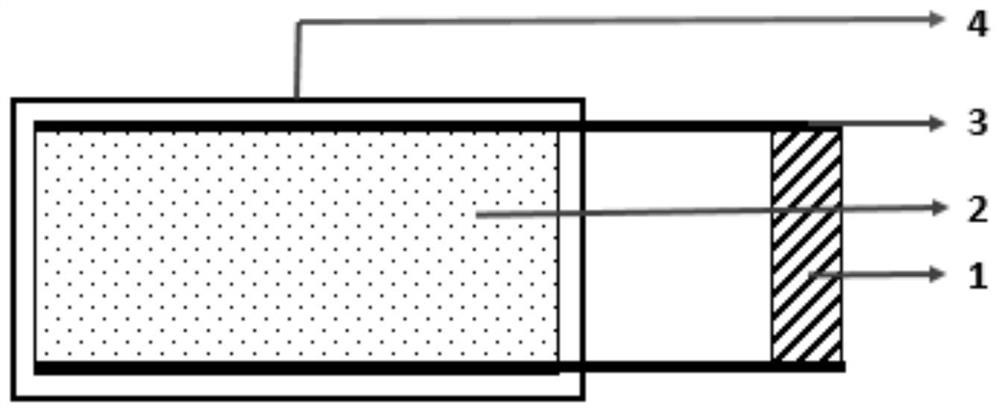

Method used

Image

Examples

Embodiment 1

[0040] On a 5cm×1cm carbon nanotube display film with a thickness of 1000μm and a volume conductivity of 10 8 S / m, hand-painted "CIOC" with glue, after it dries, apply conductive silver paste adhesive on both sides of the back, paste copper foil electrodes, dry in an oven at 125°C for 10 minutes, take polyvinyl chloride film packaging Use a heat sealer to seal the finished display film in the protective bag, and connect the power supply including the infrared display gear circuit, anti-overload protection circuit, anti-overheat protection circuit, and intermittent power supply circuit to the copper foil electrode of the display film . Use the data acquisition instrument to collect the voltage, current value, temperature of the pattern part and other parts of the display film in the circuit, and use the infrared imager to observe the infrared display effect.

[0041] The data collection results are as follows: power supply 2.0V, current 0.73A, pattern part temperature 78°C, te...

Embodiment 2

[0043] On a graphene / carbon nanotube composite display film with a size of 5cm×1cm, its thickness is 200μm, and its volume conductivity is 10 7S / m, hand-paint the words "△A01" with polyurethane emulsion. After it dries, apply conductive silver paste adhesive on both sides of the back, paste copper foil electrodes, dry in an oven at 125°C for 10 minutes, and take polyparaphenylene Seal the protective bag with ethylene glycol diformate film with a heat sealer to seal the finished display film, and seal the power supply and Copper foil electrode connections showing thin films. Use the data acquisition instrument to collect the voltage, current value, temperature of the pattern part and other parts of the display film in the circuit, and use the infrared imager to observe the infrared display effect.

[0044] The data collection results are: power supply 1.5V, current 0.63A, pattern part temperature 60°C, temperature of other parts of the display film 23°C. From image 3 It can...

Embodiment 3

[0046] On a 2.5cm×2.5cm graphene / carbon nanotube composite display film with a thickness of 120 μm and a volume conductivity of 10 6 S / m, epoxy resin solution hand-painted "ZP", after it dries, apply conductive silver paste adhesive on both sides of the back, paste copper foil electrodes, dry in an oven at 125°C for 10 minutes, take poly Use a heat sealer to seal the finished display film in the protective bag packaged with ethylene phthalate film, and seal the power supply including the infrared display gear circuit, anti-overload protection circuit, anti-overheat protection circuit, and intermittent power supply circuit Connect to the copper foil electrode of the display film. Use the data acquisition instrument to collect the voltage, current value, temperature of the pattern part and other parts of the display film in the circuit, and use the infrared imager to observe the infrared display effect.

[0047] The data collection results are: power supply 1.5V, current 0.61A,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com