Compound enzyme used for tea enzymolysis and aroma strengthening, and application thereof

A compound enzyme and enzymatic hydrolysis technology, applied in the field of compound enzymes, can solve problems such as increasing turbidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

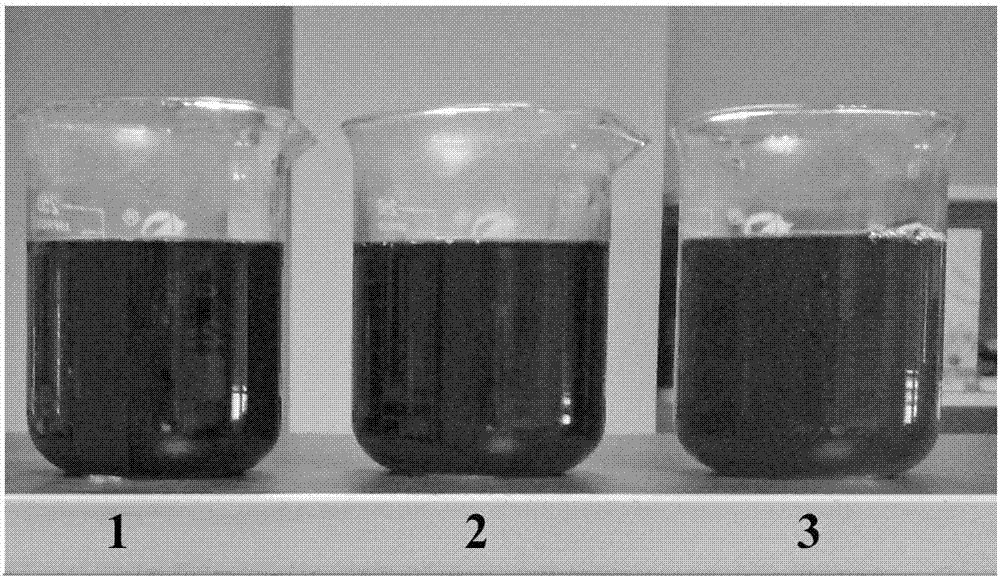

[0140] (1) Take 10.0kg of sun-dried green tea and 10.0kg of raw Pu-erh tea as raw materials, extract three times at a low temperature of 50-55°C, add water 10 times the amount of tea leaves for the first time, add water 8 times the amount of tea leaves for the second and third times, The extraction time is 1 hour each time; the extract is filtered with a 100-mesh filter cloth; the filtrate is concentrated under reduced pressure to a specific gravity of 1.035 / 68°C, and a soluble solid content of 10.5%; then it is centrifuged with a disc at a speed of 6000rpm; Concentrate to a specific gravity of 1.120 / 65° C. to obtain 16.3 kg of tea concentrate with a soluble solid content of 26.5%.

[0141] (2) Cool the tea concentrate to 55°C, take 8.0kg of the above tea concentrate, add a compound enzyme preparation to the tea concentrate, the weight ratio of each enzyme in the compound enzyme preparation is, papain: β-glucanase: flavor Glycosidase=0.5:2.0:0.1, the addition amount is 1.30% o...

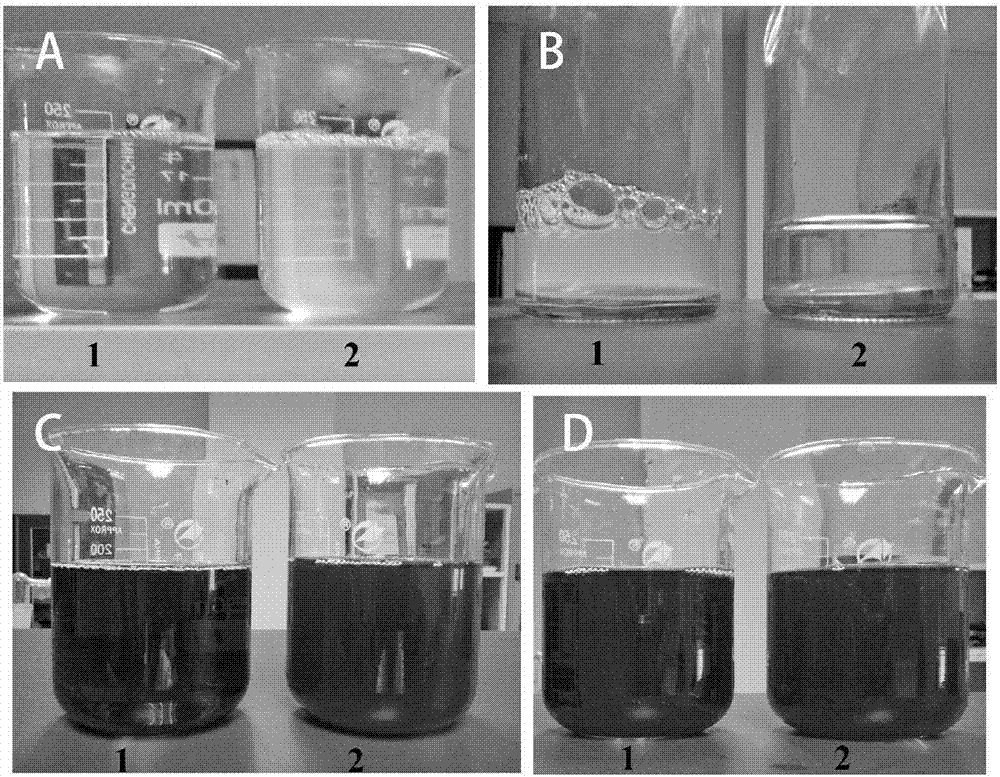

Embodiment 2

[0145] (1) Take 60.0 kg of Dianhong tea as raw material, add 16 times the amount of water of tea leaves, feed continuously, extract in countercurrent at 70-80°C low-temperature pipeline, and the total extraction time is 3 hours; filter the extract with 100-mesh filter cloth; decompress the filtrate Concentrate to a specific gravity of 1.030 / 70°C and a soluble solid content of 15.3%; then disc centrifuge at a speed of 6000rpm; concentrate the centrifuge to a specific gravity of 1.130 / 65°C to obtain a tea concentrate with a soluble solid content of 29.4% 46.0 kg.

[0146] (2) Get 10.0kg of the above-mentioned tea concentrate, cool the tea concentrate to 55° C., add a compound enzyme preparation in the tea concentrate, and the weight ratio of each enzyme in the compound enzyme preparation is, papain: β-glucanase= 0.5:2.25, the addition is 2.75% of the weight of the concentrated solution, that is, add 50g of papain (0.5% of the weight of the concentrated solution) and 225g of β-gl...

Embodiment 3

[0150] (1) Take 30.0kg of compound tea of Pu’er cooked tea and sun-dried green tea as raw material (sun-dried green tea accounts for 50%), extract at 94°C for three times, add 10 times the amount of water for the first time, and secondly, Add water of 8 times the amount of tea leaves three times, and the extraction time is 1 hour each time; the extract is filtered with a 100-mesh filter cloth; the filtrate is concentrated under reduced pressure to a specific gravity of 1.028 / 65°C, and a soluble solid content of 12.5%; Disc centrifugation at a rotational speed of 6000 rpm; the centrifuged liquid is then concentrated to a specific gravity of 1.120 / 70° C. to obtain 23.5 kg of a tea concentrate with a soluble solid content of 25.0%.

[0151] (2) Cool the tea concentrate to 55°C, get 10.0kg tea concentrate, add a compound enzyme preparation in the tea concentrate, the weight ratio of each enzyme in the compound enzyme preparation is, papain: β-glucanase=0.4 : 1.0, the addition is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com