Preparation method of biomass-derived porous carbon confinement monatomic metal composite material

A metal composite material, porous carbon technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, etc., can solve the problem of poor coordination stability of heteroatoms, metal active components Easy to aggregate, difficult to scale production and other problems, to achieve the effects of low cost, improved catalytic activity and electronic conductivity, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Precursor preparation process: phthalocyanine (0.412g) and iron phthalocyanine (0.228g) were dispersed in ethanol / tetrahydrofuran (100mL / 100mL) mixture, and complexed with stirring at 25°C for 5h. Subsequently, a homogeneous suspension of pomelo peel powder / isopropanol (0.3 g / 200 mL) was mixed into the above mixed solution, and stirred at 25° C. for 12 h. The mixed solution was placed in an 85°C water bath to evaporate the solvent while stirring, and then the sample after the solvent evaporation was baked at 100°C for 48 hours to obtain a precursor.

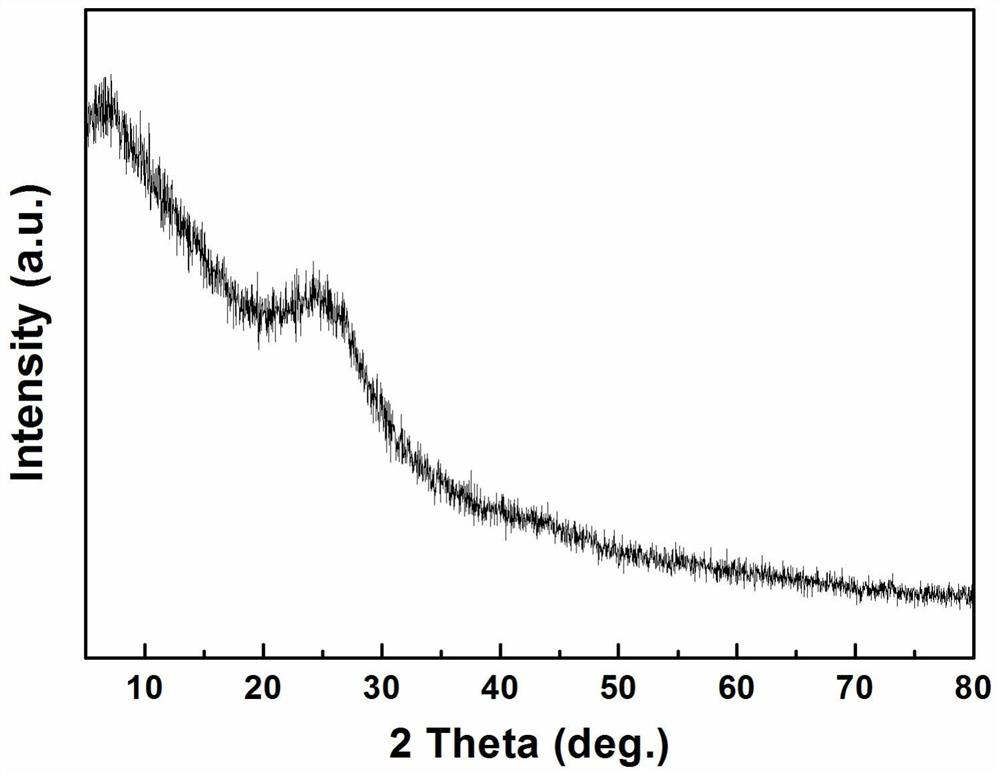

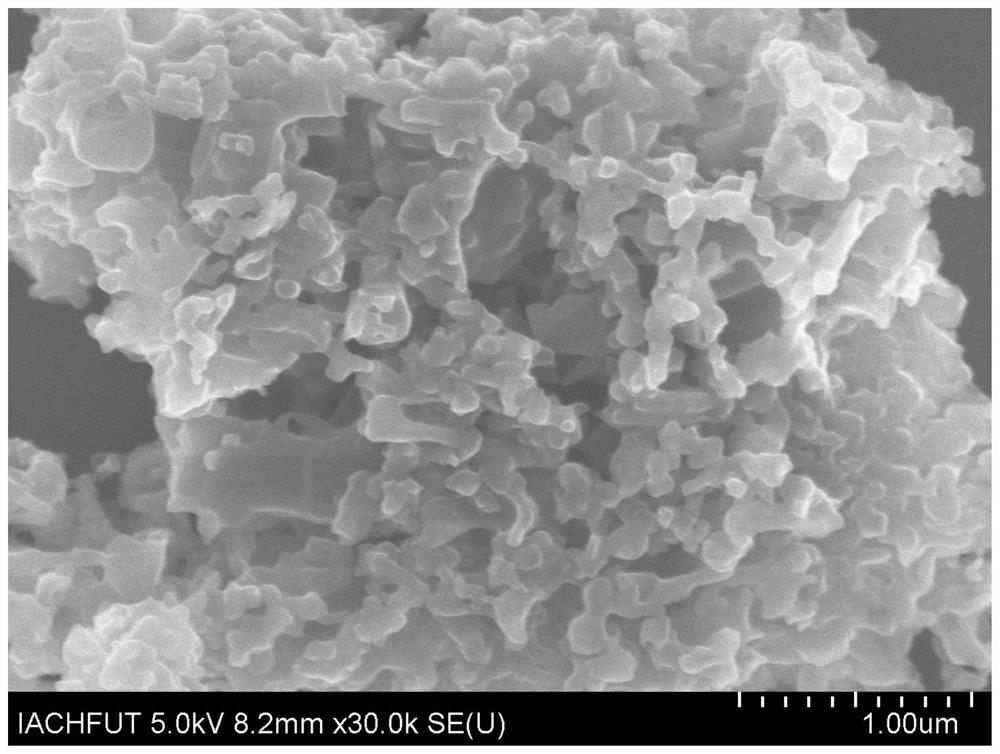

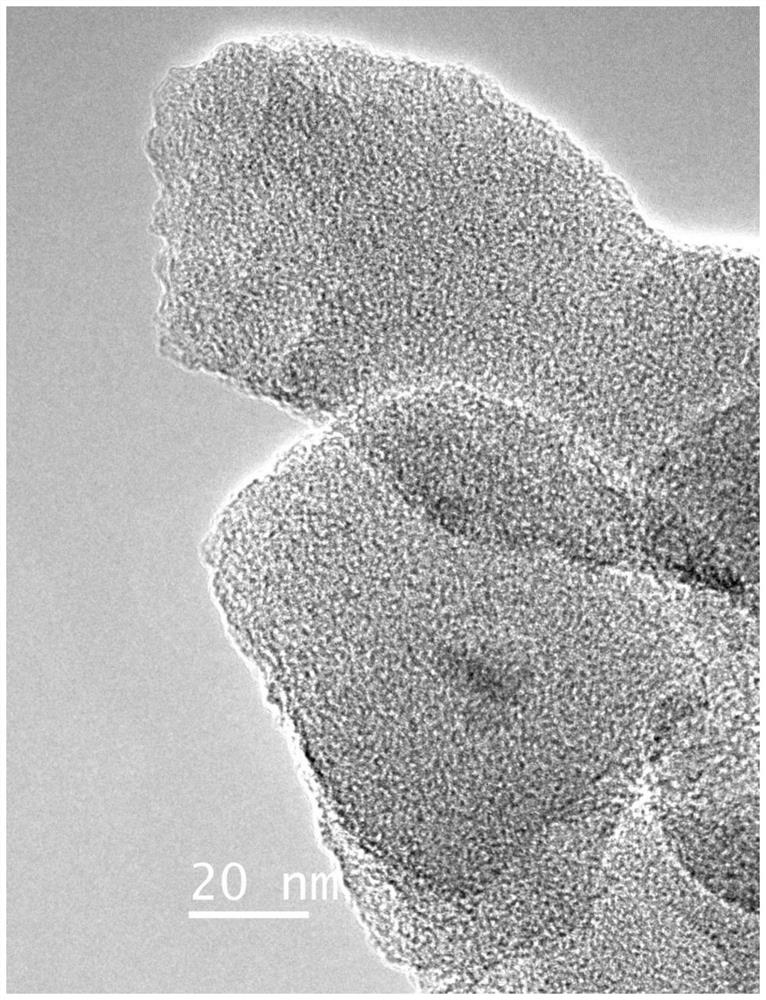

[0030](2) Carbonization process: the precursor obtained in step (1) was placed in a tube furnace for direct pyrolysis (the pyrolysis temperature was 600 °C, the pyrolysis time was 1 h, and the heating rate was 5 °C min -1 , N 2 The gas flow rate is 0.2 mL / min). The pyrolysis product was acid-washed in 2mol / L, 100mL nitric acid solution at 25°C for 12h, the obtained catalyst was centrifuged three times with ethanol, w...

Embodiment 2

[0037] In this example, a biomass-derived porous carbon-confined iron single-atom metal composite was prepared in the same manner as in Example 1, with the only difference being that orange peel powder was used instead of grapefruit peel powder.

[0038] After testing, the mass of the composite material prepared in this example is ~0.2534g, the loading amount of monoatomic iron is 2.2wt%, and the monoatomic iron is highly dispersed in the porous carbon framework derived from orange peel, with high catalytic activity.

[0039] The same method as in Example 1 was used to test the catalytic performance of the composite material prepared in this example. After testing, the degradation rate of organic pollutant Golden Orange II and heavy metal pollutant hexavalent chromium reached 100%.

Embodiment 3

[0041] In this example, a biomass-derived porous carbon-confined iron single-atom metal composite was prepared in the same manner as in Example 1, with the only difference being that banana peel powder was used instead of pomelo peel powder.

[0042] According to tests, the mass of the composite material prepared in this example is ~0.2284g, the loading amount of monoatomic iron is 1.8wt%, and the monoatomic iron is highly dispersed in the porous carbon framework derived from banana peel, with high catalytic activity.

[0043] The same method as in Example 1 was used to test the catalytic performance of the composite material prepared in this example. After testing, the degradation rate of organic pollutant Golden Orange II and heavy metal pollutant hexavalent chromium reached 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com