A stirring device having an automatic cleaning function

A stirring device and automatic cleaning technology, applied to mixers with rotating stirring devices, mixer accessories, transportation and packaging, etc., can solve problems such as unfavorable cleaning, many residues, affecting mixing work, etc., to achieve automatic control and speed up Production efficiency and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

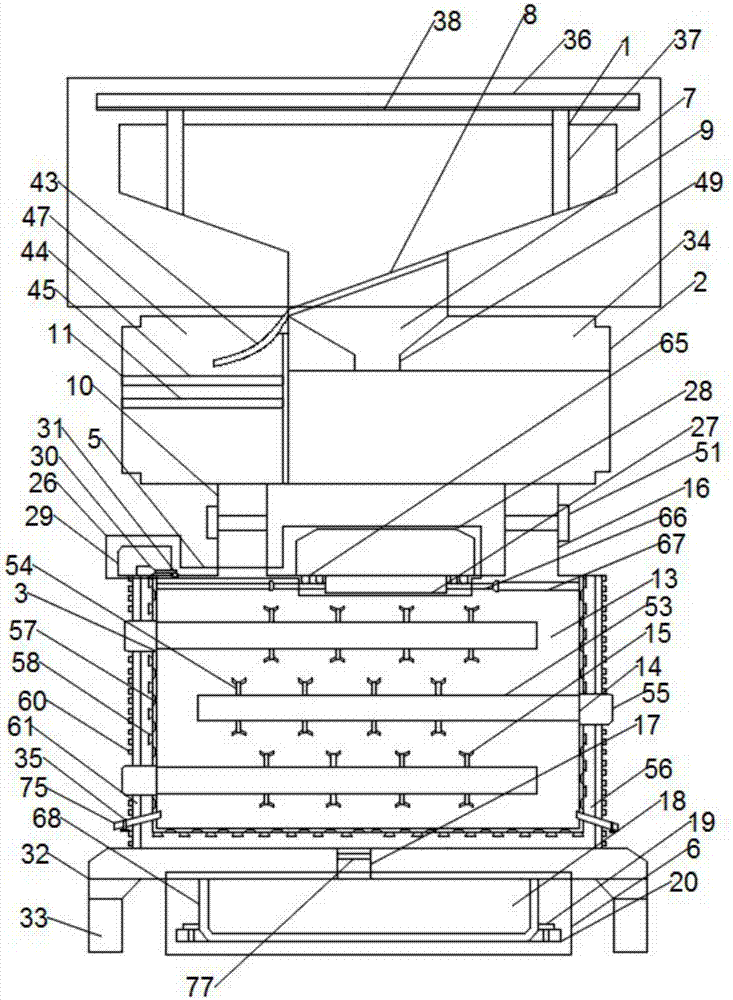

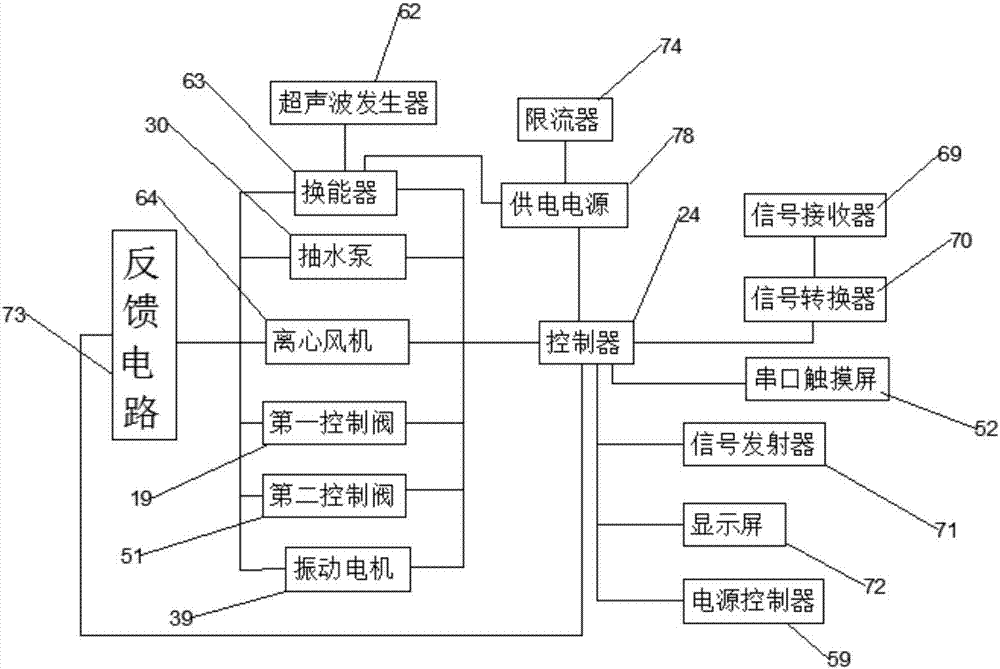

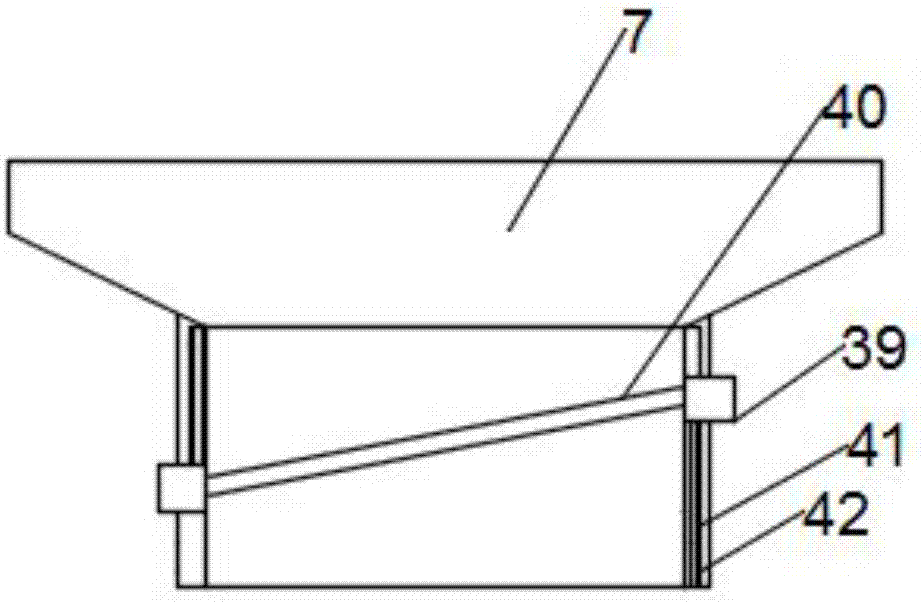

[0024] Such as Figure 1-Figure 8 As shown, the present invention provides a kind of stirring device with automatic cleaning function, comprises feeding device 1, refining device 2, stirring device 3, control device 4, cleaning device 5 and discharging device 6, described feeding device 1 includes a feed hopper 7, a vibrating screen 8 and a discharge hopper 9, the top of the feed hopper 7 is provided with a sealing cover 36, and the bottom end of the sealing cover 36 is connected with a hydraulic rod 37, and the hydraulic rod 37 is arranged on the feed The inner wall of the bucket 7, the bottom surface of the sealing cover 36 is provided with a sealing ring 38. When feeding, the height is stretched by the hydraulic action of the hydraulic rod 37, and the sealing cover 36 and the feeding hopper 7 are separated, so that the required stirring The materials are sequentially discharged into the feed hopper 7. After the feed is completed, the sealing cover 36 is closed by the hydrau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com