A kind of interior wall putty powder and its production process

A technology for interior wall putty powder and production process, applied in the field of putty powder, can solve the problems of not meeting people's daily needs, not having other functions, endangering human health, etc., to increase thermal insulation and fire resistance, and improve comfort and safety. , the effect of enhancing immunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

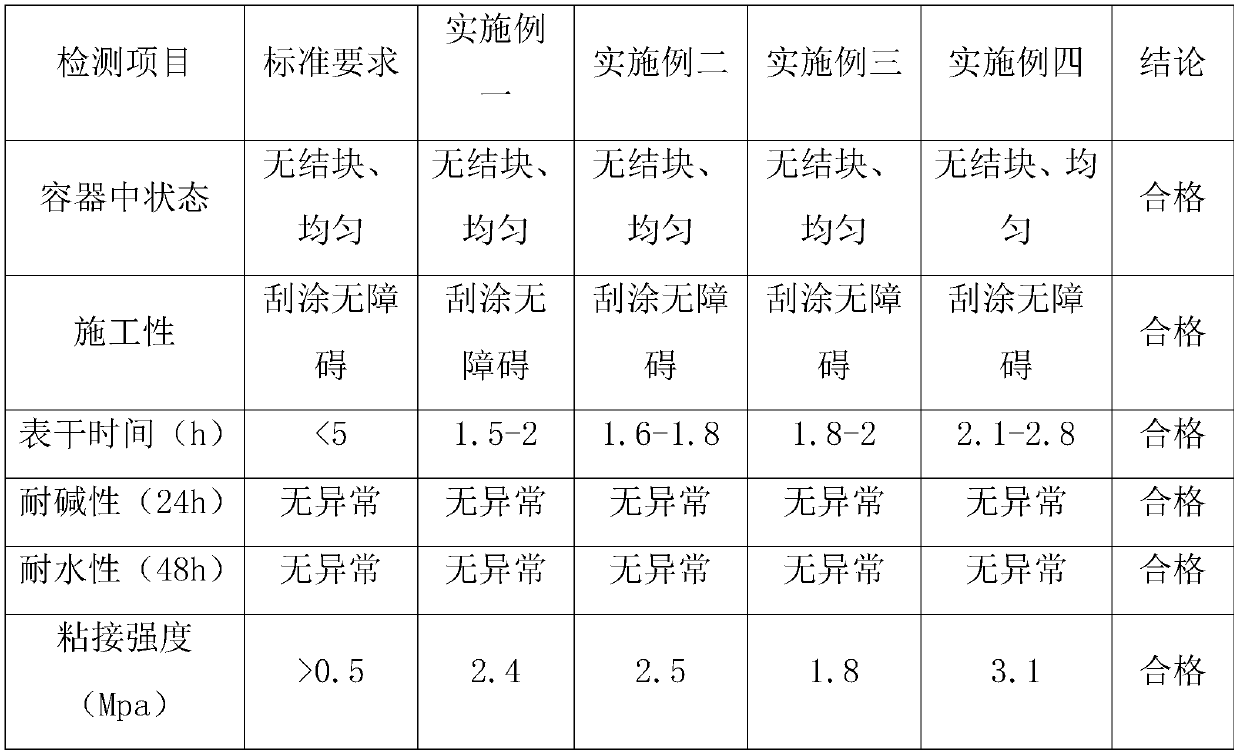

Examples

Embodiment 1

[0026] An interior wall putty powder, comprising the following components by weight: 15 parts of heavy calcium carbonate powder, 10 parts of gray calcium powder, 10 parts of titanium dioxide, 15 parts of latex powder, 5 parts of japonica rice gel powder, and 10 parts of expanded perlite 8 parts, 8 parts of shell powder, 2.5 parts of HPMC and 8 parts of other auxiliary agents; The other auxiliary agents include the following components by weight: 4 parts of lavender powder, 2 parts of peppermint powder and 2 parts of aloe powder.

Embodiment 2

[0028] An interior wall putty powder, comprising the following components by weight: 30 parts of heavy calcium carbonate powder, 15 parts of gray calcium powder, 15 parts of titanium dioxide, 20 parts of latex powder, 10 parts of japonica rice gel powder, and 20 parts of expanded perlite 12 parts, 12 parts of shell powder, 3.5 parts of HPMC and 16 parts of other auxiliary agents; the other auxiliary agents include the following components by weight: 8 parts of lavender powder, 4 parts of mint powder and 4 parts of aloe powder.

Embodiment 3

[0030] An interior wall putty powder, comprising the following components by weight: 22.5 parts of heavy calcium carbonate powder, 12.5 parts of gray calcium powder, 12.5 parts of titanium dioxide, 17.5 parts of latex powder, 7.5 parts of japonica rice gel powder, and 15 parts of expanded perlite 10 parts, 10 parts of shell powder, 3 parts of HPMC and 12 parts of other auxiliary agents; the other auxiliary agents include the following components by weight: 6 parts of lavender powder, 3 parts of mint powder and 3 parts of aloe powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com